Hello all.

PatCVT

In the PatCVT a sprocket or gearwheel (actually an idler) is intermeshed with "teeth" on both spans of the V-belt.

The displacement of the center of the sprocket varies positively the transmission ratio:

enabling various "modes" of operation:

Drive Mode:

The lever that holds the sprocket is released to pivot freely about the cross; the CVT runs automatically under the control of a variator in the one conical pulley and of a spring / torque cam in the other conical pulley.

Sport Mode:

Performance oriented.

A control spring pushes the lever towards the conical pulley with the spring / torque cam; the CVT continues to run "fully automatic", but it selects shorter transmission ratios.

Economy Mode:

For green, quiet, reliable, comfortable operation.

The control spring pushes the lever towards the variator's conical pulley; the CVT continues to run "fully automatic" (as in the "Drive Mode"), but it selects longer transmission ratios.

Manual Mode:

The rider / driver displaces "manually" the lever about the cross to select any transmission ratio from the available infinity, regardless of what the "variator / spring / torque cam" command.

By locking the lever at a number of discrete positions, the CVT replicates a manual gear box.

In all modes the sprocket acts as a "baffle roller" (drive belt tensioner), too.

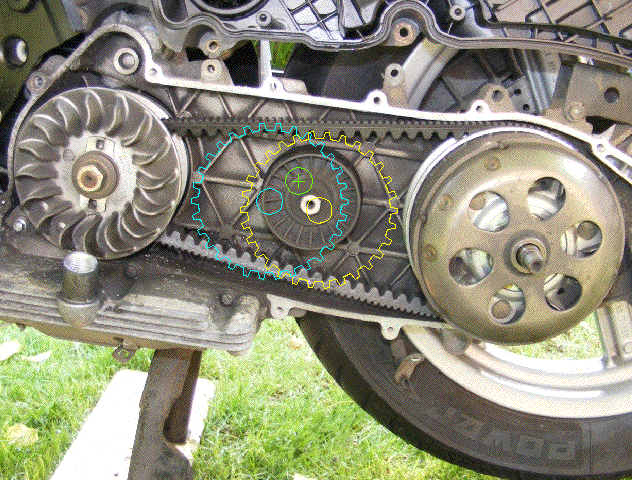

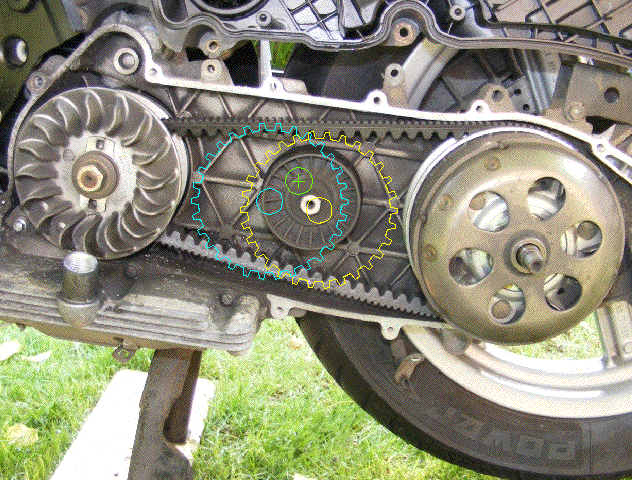

The available space inside the CVT of many scooters (like, for instance, the Sport-City Aprilia 250cc, below) is more than what the PatCVT needs:

How it works?

With the sprocket engaged with the toothed-V-belt as in the animation, the sprocket divides the V-belt in two parts (one at left of the sprocket and another at right of the sprocket), with each part maintaining its length constant.

The move away of the center of the sprocket from the one conical pulley causes the decrease of the effective diameter the V-belt is running on this conical pulley, and the increase of the effective diameter the V-belt is running on the other conical pulley.

For more: http://www.pattakon.com/pattakonPatCVT.htm

Thoughts?

Thanks

Manolis Pattakos

PatCVT

In the PatCVT a sprocket or gearwheel (actually an idler) is intermeshed with "teeth" on both spans of the V-belt.

The displacement of the center of the sprocket varies positively the transmission ratio:

enabling various "modes" of operation:

Drive Mode:

The lever that holds the sprocket is released to pivot freely about the cross; the CVT runs automatically under the control of a variator in the one conical pulley and of a spring / torque cam in the other conical pulley.

Sport Mode:

Performance oriented.

A control spring pushes the lever towards the conical pulley with the spring / torque cam; the CVT continues to run "fully automatic", but it selects shorter transmission ratios.

Economy Mode:

For green, quiet, reliable, comfortable operation.

The control spring pushes the lever towards the variator's conical pulley; the CVT continues to run "fully automatic" (as in the "Drive Mode"), but it selects longer transmission ratios.

Manual Mode:

The rider / driver displaces "manually" the lever about the cross to select any transmission ratio from the available infinity, regardless of what the "variator / spring / torque cam" command.

By locking the lever at a number of discrete positions, the CVT replicates a manual gear box.

In all modes the sprocket acts as a "baffle roller" (drive belt tensioner), too.

The available space inside the CVT of many scooters (like, for instance, the Sport-City Aprilia 250cc, below) is more than what the PatCVT needs:

How it works?

With the sprocket engaged with the toothed-V-belt as in the animation, the sprocket divides the V-belt in two parts (one at left of the sprocket and another at right of the sprocket), with each part maintaining its length constant.

The move away of the center of the sprocket from the one conical pulley causes the decrease of the effective diameter the V-belt is running on this conical pulley, and the increase of the effective diameter the V-belt is running on the other conical pulley.

For more: http://www.pattakon.com/pattakonPatCVT.htm

Thoughts?

Thanks

Manolis Pattakos