- Joined

- Oct 29, 2011

- Messages

- 287

- Reaction score

- 2

After spending several hours making a new piston rod for a Stuart Beam, I had something like this (that's the old rod at the top):

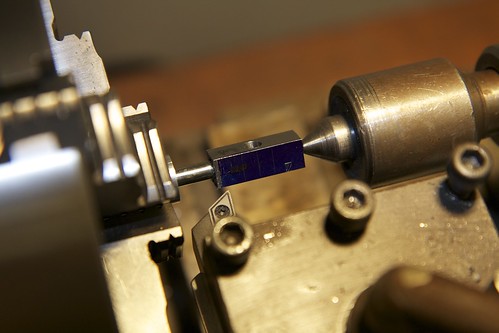

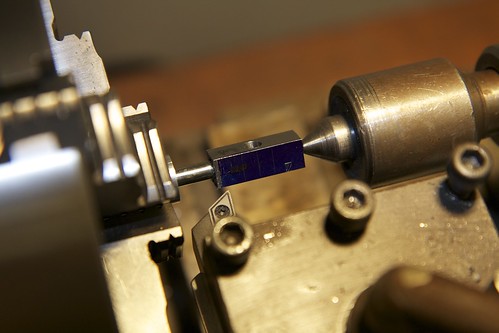

Now to turn down the shoulder, and shorten it up:

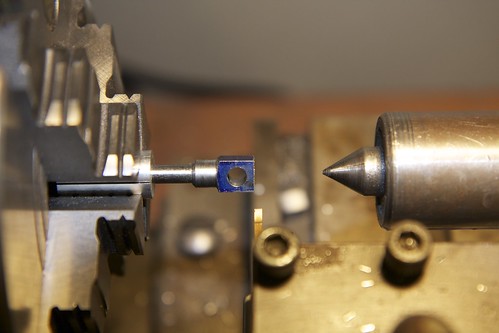

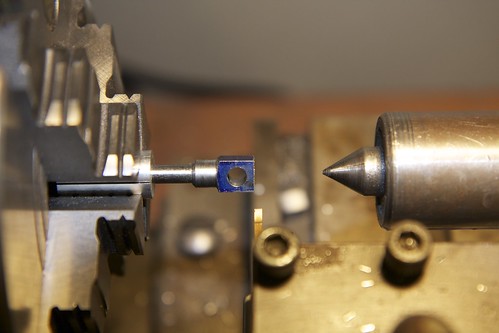

Gee, thought I, I'll just use my handy parting tool to cut off the top! It's held by a live center, what can go wrong?? As the tool was getting towards the point of no return, I thought "mmm, maybe I should back off and cut the last part with the hacksaw". Of course, just then the tool broke through, something went "thunk", and the top end of my piston rod spun around with an ominous wobble

It's not too obvious from the photo, but the part is junk.

In hindsight, I should have had the square part in the 4-jaw for this operation. Ah well!

Now to turn down the shoulder, and shorten it up:

Gee, thought I, I'll just use my handy parting tool to cut off the top! It's held by a live center, what can go wrong?? As the tool was getting towards the point of no return, I thought "mmm, maybe I should back off and cut the last part with the hacksaw". Of course, just then the tool broke through, something went "thunk", and the top end of my piston rod spun around with an ominous wobble

It's not too obvious from the photo, but the part is junk.

In hindsight, I should have had the square part in the 4-jaw for this operation. Ah well!