- Joined

- Aug 25, 2007

- Messages

- 3,890

- Reaction score

- 715

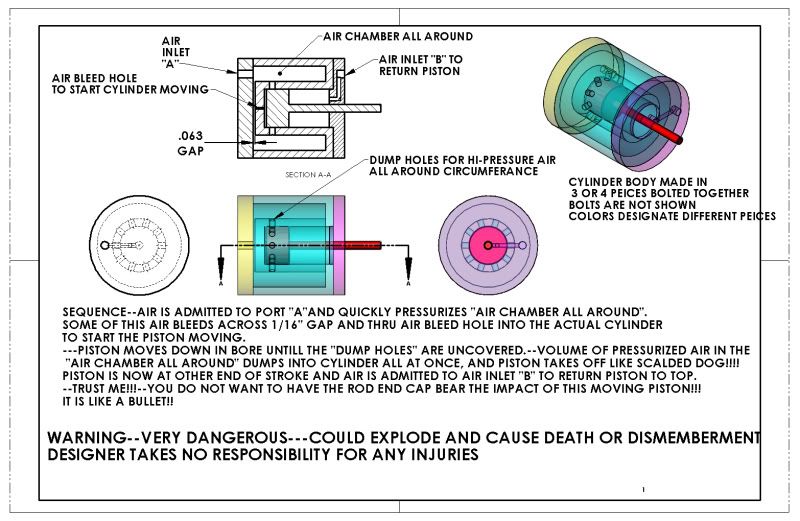

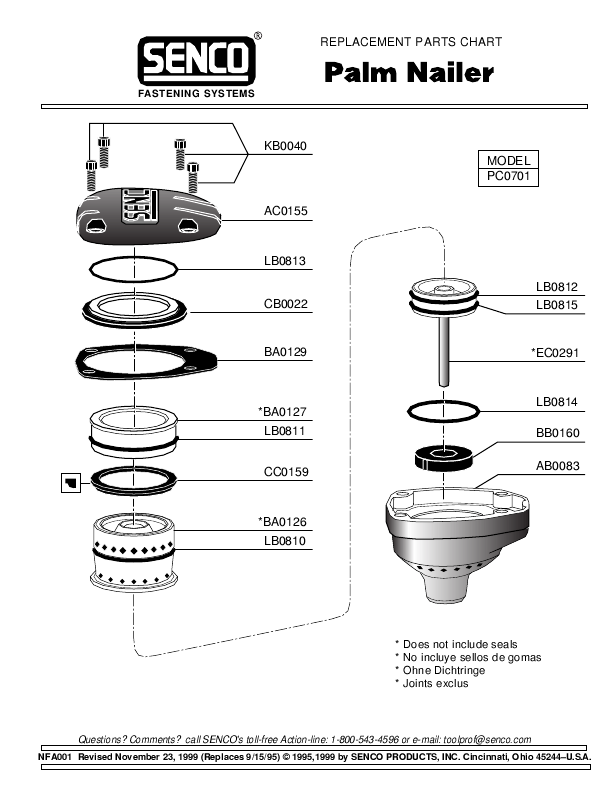

Do any of you know how a Palm Nailer works? It runs on air, you put a nail inside the tube in the bottom, then when you press lightly against the wood, a piston inside moves up and down driving the nail into the wood. I've looked at parts diagrams on the web and there is a piston inside a cylinder which has rows of holes around the top and the bottom. A valve in the form of a sleeve slides up and down around the outside of the cylinder so that it can cover either the top or bottom row of holes but not both at once (I think). I can't figure out for the life of me how it works, but the design looks like it might be applied to a small, compressed air engine.

g

g

Chuck

Chuck