Sixtysixdeuce

Member

- Joined

- Jun 4, 2014

- Messages

- 18

- Reaction score

- 25

It is dubbed AR-7.5, a 50% scale AR-15. I give you my partial build as it sits now, nearing the close of week 3 and after about 75-80 hours of machine and finishing work:

That is a normal 5.56 size AR receiver on top. Don't know how many we have here who are familiar with the AR-15, but for those who are, the scale should be rather striking.

Now, before anyone asks, yes, it is 100% legal in the USA to build your own title I firearm for personal use. They needn't be serialized, and they can even be legally sold at a later time, so long as they weren't build with the intent to sell.

Anyway, I still have a long, loooong way to go. Chambering is going to be .17 Mach 2, which is a .22 long rifle necked down to .17 caliber. I still need to procure a barrel to modify, as rifling barrels is one thing I'm not yet equipped to handle. I have not yet made: Barrel nut/Delta ring ( will be one piece), front sight, flash hider, forward HG retainer, hand guards, charging handle, stock, faux gas key, buffer, bolt catch, magazine catch, extractor, ejector and firing pin.

This is where it all started with a piece of .860" 7075-T6 on Sunday, October 5th:

Carving trigger, hammer, disconnector out of D2 tool steel:

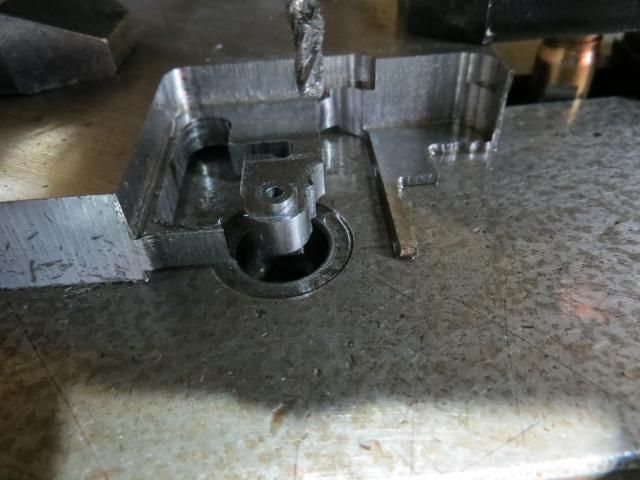

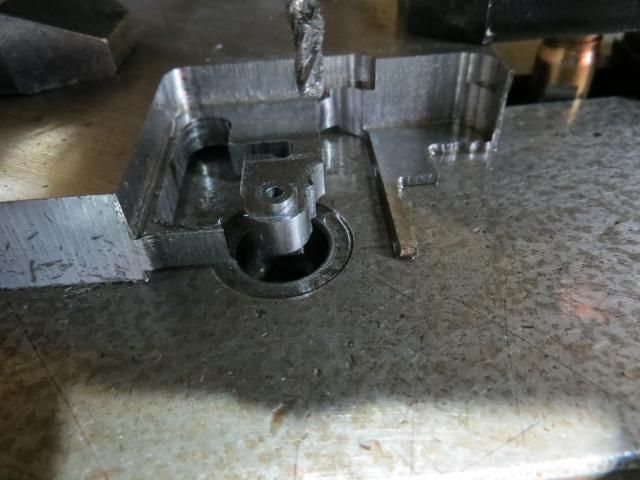

Installed, and receiver extension housing threaded (5/8-24):

Unfortunately, I totally forgot any pics while I was carving out the selector. Oh well.

Moving on, now time to get after the 6061-T651 upper half:

Threading the barrel housing in 3/4-28 before cutting away too much material, which would risk tweaking the piece:

Starting to show signs of life:

In the rough:

The pint sized homogenous bolt/carrier I cut from an air hammer chisel. Should last forever, but it was slow going. This super tough, super hard alloy destroyed a half dozen carbide end mills and over 20 HSS, TiAlN and cobalt drill bits

In the upper, as I try to gauge depth for the modified Savage Mk II mag that will be used until I get around to making a forming die to do scale magazines:

Today was receiver extension ("buffer tube") day. Also cut from 7075-T6, this is how the bulk of it was formed:

Using a 7" long 3/8" carbide end mill and trying to keep the piece rigid enough to avoid chatter proved futile. I just resigned myself to the fact that there would be a couple blemishes that even 2+ hours of hand finishing wouldn't remove. Next time I'll use a 7/16" 4 flute for this process.

It will be a fully functional 6 position carbine stock, which I will be carving out of ABS as I did the grip.

Remember, I have no CNC capability. This is all done on these 3 machines:

And with a lot of elbow grease using die grinders, dremels and assorted hand tools.

So that's about it for now. When completed, it will be a 50% scale blow-back operated pistol. I say pistol, because the stock will obvisouly be useless at only 5.2" fully extended. Hopefully ATF will agree with me and allow this to be a title I handgun rather than forcing me to register another title II short barreled rifle. We shall see!

That is a normal 5.56 size AR receiver on top. Don't know how many we have here who are familiar with the AR-15, but for those who are, the scale should be rather striking.

Now, before anyone asks, yes, it is 100% legal in the USA to build your own title I firearm for personal use. They needn't be serialized, and they can even be legally sold at a later time, so long as they weren't build with the intent to sell.

Anyway, I still have a long, loooong way to go. Chambering is going to be .17 Mach 2, which is a .22 long rifle necked down to .17 caliber. I still need to procure a barrel to modify, as rifling barrels is one thing I'm not yet equipped to handle. I have not yet made: Barrel nut/Delta ring ( will be one piece), front sight, flash hider, forward HG retainer, hand guards, charging handle, stock, faux gas key, buffer, bolt catch, magazine catch, extractor, ejector and firing pin.

This is where it all started with a piece of .860" 7075-T6 on Sunday, October 5th:

Carving trigger, hammer, disconnector out of D2 tool steel:

Installed, and receiver extension housing threaded (5/8-24):

Unfortunately, I totally forgot any pics while I was carving out the selector. Oh well.

Moving on, now time to get after the 6061-T651 upper half:

Threading the barrel housing in 3/4-28 before cutting away too much material, which would risk tweaking the piece:

Starting to show signs of life:

In the rough:

The pint sized homogenous bolt/carrier I cut from an air hammer chisel. Should last forever, but it was slow going. This super tough, super hard alloy destroyed a half dozen carbide end mills and over 20 HSS, TiAlN and cobalt drill bits

In the upper, as I try to gauge depth for the modified Savage Mk II mag that will be used until I get around to making a forming die to do scale magazines:

Today was receiver extension ("buffer tube") day. Also cut from 7075-T6, this is how the bulk of it was formed:

Using a 7" long 3/8" carbide end mill and trying to keep the piece rigid enough to avoid chatter proved futile. I just resigned myself to the fact that there would be a couple blemishes that even 2+ hours of hand finishing wouldn't remove. Next time I'll use a 7/16" 4 flute for this process.

It will be a fully functional 6 position carbine stock, which I will be carving out of ABS as I did the grip.

Remember, I have no CNC capability. This is all done on these 3 machines:

And with a lot of elbow grease using die grinders, dremels and assorted hand tools.

So that's about it for now. When completed, it will be a 50% scale blow-back operated pistol. I say pistol, because the stock will obvisouly be useless at only 5.2" fully extended. Hopefully ATF will agree with me and allow this to be a title I handgun rather than forcing me to register another title II short barreled rifle. We shall see!