Hello all,

Just started this project and looking at the speed I work its going to tale some time. I was asked to detail my progress with pictures so here is the start of the job.

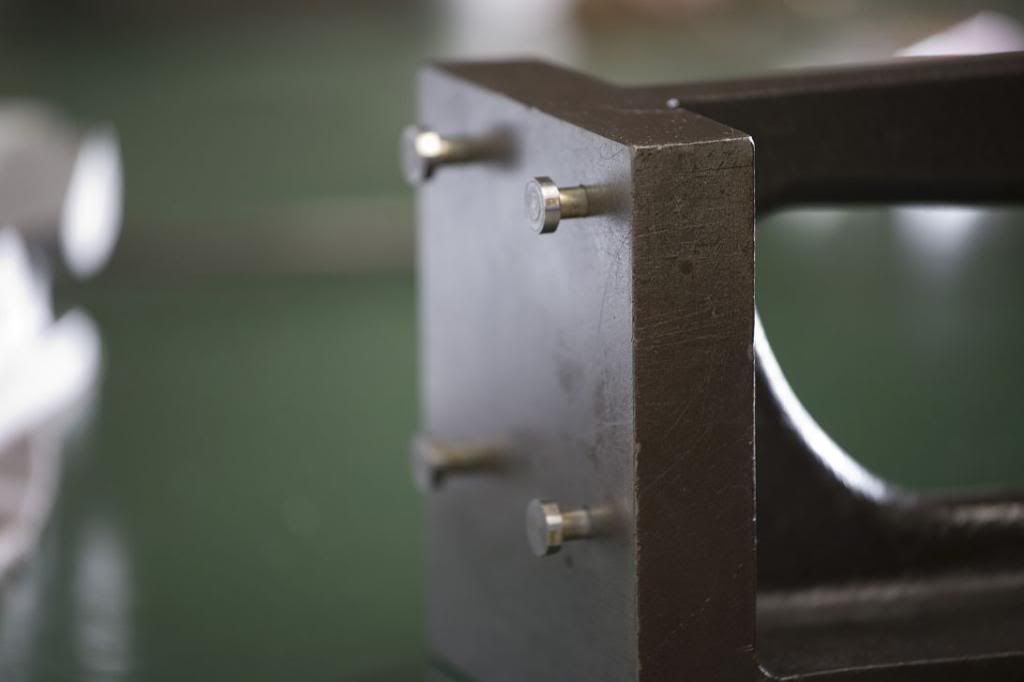

The castings look like this :

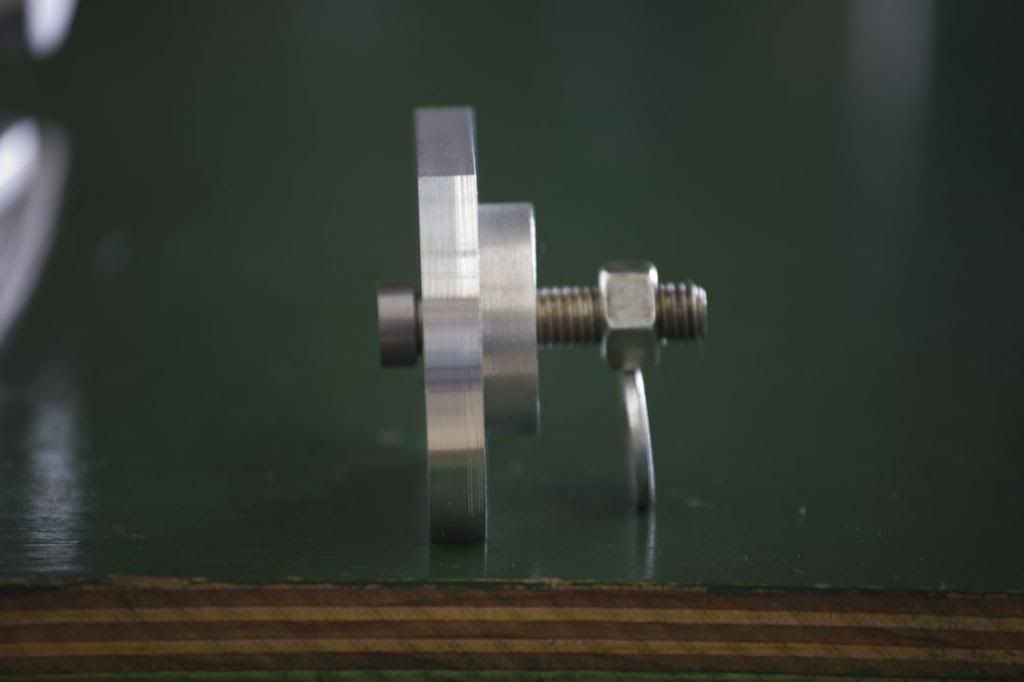

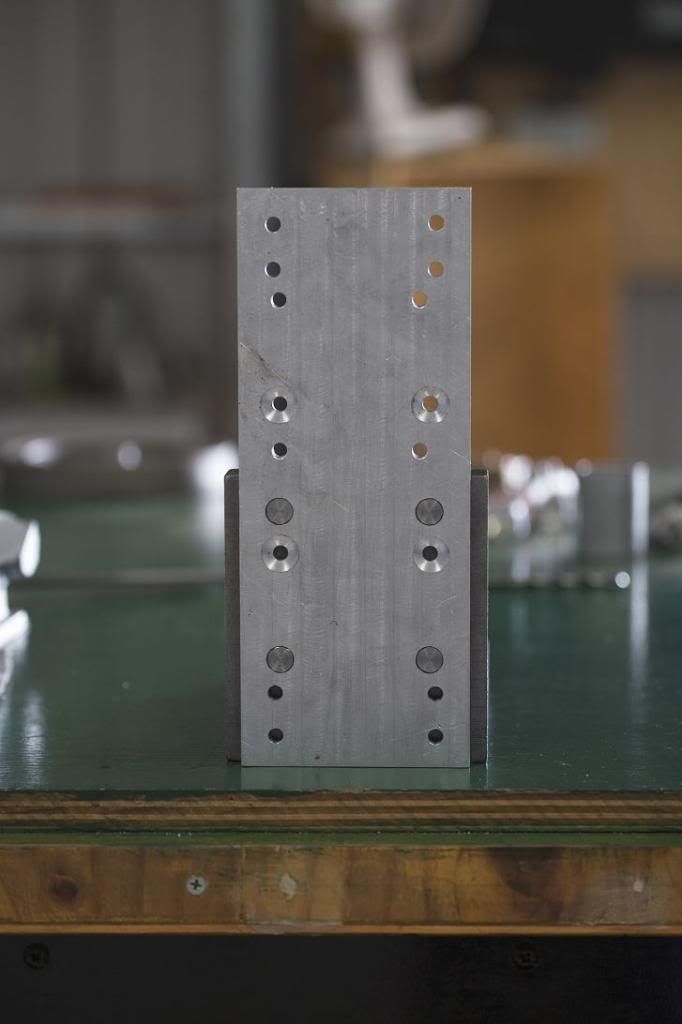

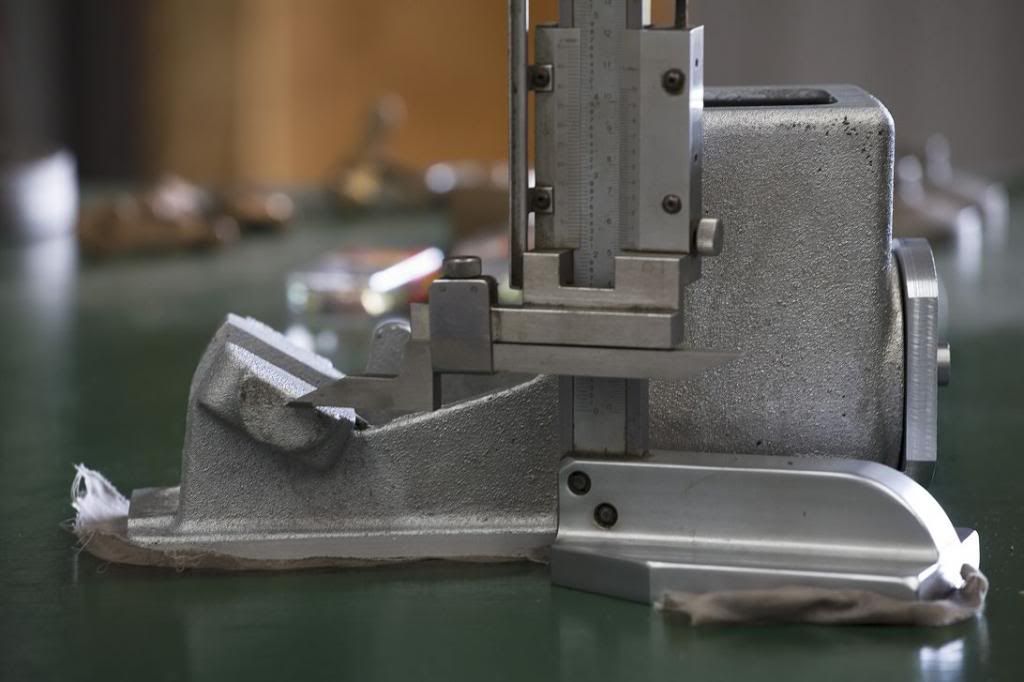

The first thing to do is to machine the castings to get the reference surfaces. Some pieces are easier to do than other pieces. Cleaning up the bottom mount was easy and here is a pic of the work holding :

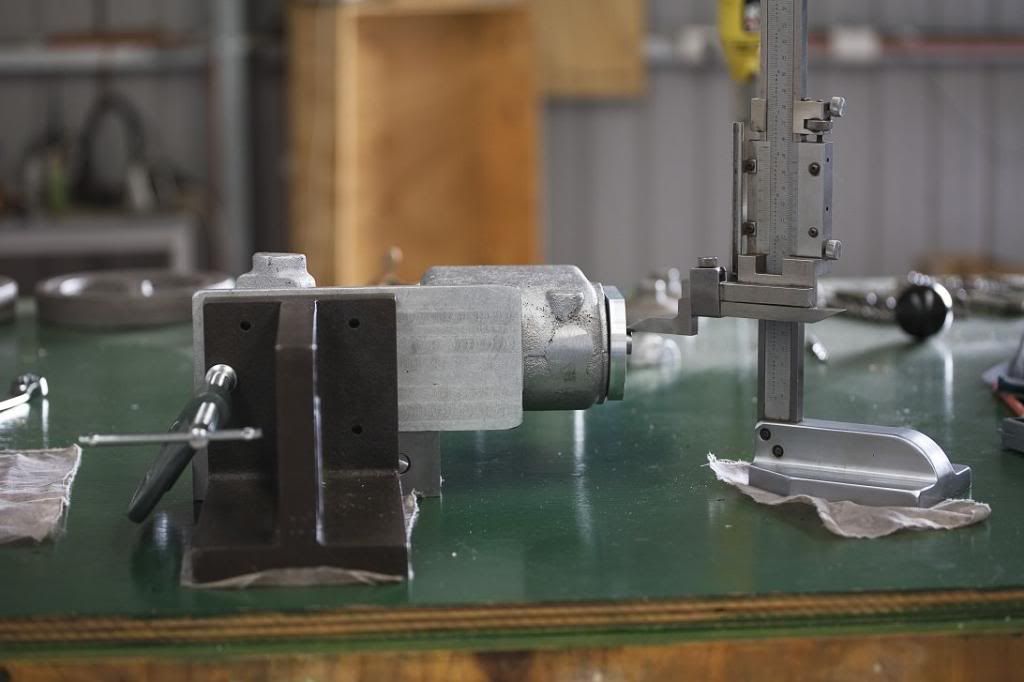

The top piece is a bit more "curly". The reference surface is the castings bottom surface and two of the rectangle edges. Here is how I setup. The accurate Wixey digital "spirit level" and angle finder (used in set up of astronomy instruments) is used to make the reference "parallel " with the mill table and the dial indicator gets the reference with the x and y travel:

By suitable shimming of the casting in the vise the surface is made true.

Well this is the start.

Just started this project and looking at the speed I work its going to tale some time. I was asked to detail my progress with pictures so here is the start of the job.

The castings look like this :

The first thing to do is to machine the castings to get the reference surfaces. Some pieces are easier to do than other pieces. Cleaning up the bottom mount was easy and here is a pic of the work holding :

The top piece is a bit more "curly". The reference surface is the castings bottom surface and two of the rectangle edges. Here is how I setup. The accurate Wixey digital "spirit level" and angle finder (used in set up of astronomy instruments) is used to make the reference "parallel " with the mill table and the dial indicator gets the reference with the x and y travel:

By suitable shimming of the casting in the vise the surface is made true.

Well this is the start.