Mosey

Well-Known Member

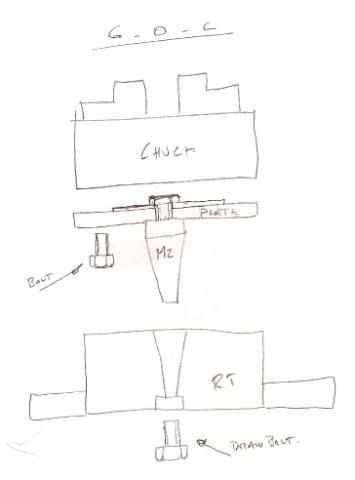

I would like suggestions for mounting work on the RT. I have 2 tables, a Sherline that accepts a threaded screw or post into the center hole, not too difficult. And, a 6" Phase 1 with a MT-2 hole through the center. If I put an MT-2 collet in the center hole, I can tighten the collet from below with a bolt up from the bottom of the table into the collet, but it will protrude out the bottom of the table. Block up the table?