Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

A few years back when I had to go to work for a living, One of the coworkers named Kip was telling me of going to a yard sale and buying a little metal cutting lathe for $40. He did not know what kind it was, but it sounded intriguing. Kip builds things by welding, but does not have much interest in machining, so I offered to buy it from him to put in my collection. I even got up to where I offered three times what he paid, but it simply was not for sale for money. However he was very willing to trade it for one of my miniature muzzle loading rifles. I don't normally do gun work for people outside my family, but Kip was almost like family and I wanted that lathe, so I agreed.

I failed to take a picture after the rifle was finished, but below is one taken during construction. There is a full size Hawken muzzle loader reproduction that I built for myself leaning against the tool cabinet for size reference. Then a half size one right below it, and the one in the vise under construction is the one that was traded for the lathe.

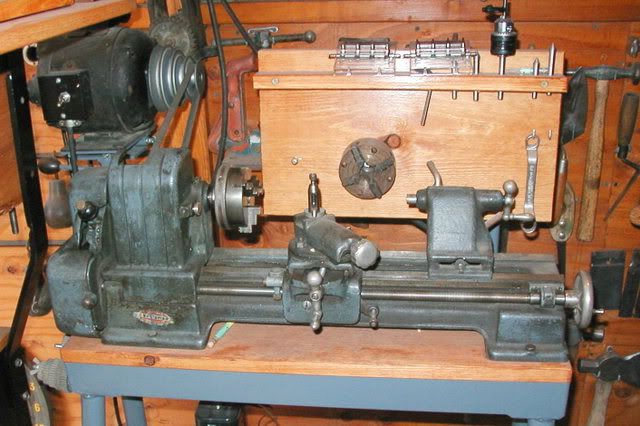

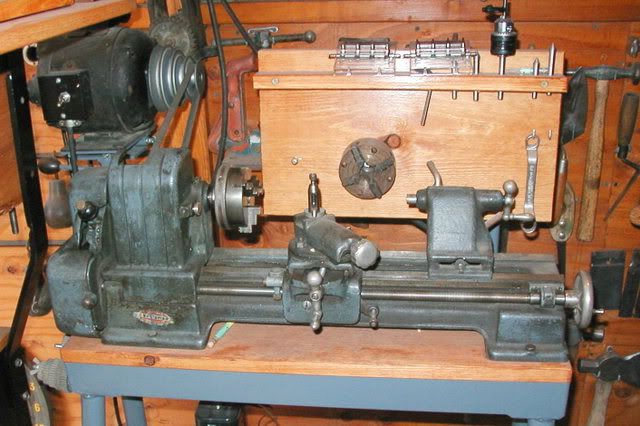

It took about a hundred hours to build the miniature, because every part has to be hand made from scratch. I finally finished it and delivered it to him, and then he brought the lathe for me the next day, like a mail order bride. That lathe had so much crud on it you could not even tell what it was. But some solvent and a parts washing brush fixed that. I uncovered a decal that said "Craftsman".

It was a model AA109.

Was it a fair trade? You bet! We both got what we wanted. I got more iron, and he might have got more value, but what is a few hours between good friends.

At home Kip had a 4 year old grandson pose with the rifle while they took some pictures and that kid was really "hamming" it up. When the picture taking was finished, Kip went to get the rifle and that was not an option as far as the grandson was concerned. Kip had to pry his fingers off to get it back.

Shortly after I got the AA109 set up on display, my friend George from Brigham City brought me a box of lathe parts that someone had given to him. Apparently someone had taken it apart to paint it and then never reassembled it again. The main parts were there, but so many of the little parts had vanished, like gibs, half nut, handles, etc. etc. that it was no longer serviceable. It was a model 80. Just a newer version of the AA109. Most of the working parts are interchangeable. After sitting in the nurturing atmosphere of my workshop it began to grow those missing parts until it became functional again.

Both lathes are now on display. They would do machining, but not the way my new Jet does, so they can just sit there and amuse our visitors.

Birk

I failed to take a picture after the rifle was finished, but below is one taken during construction. There is a full size Hawken muzzle loader reproduction that I built for myself leaning against the tool cabinet for size reference. Then a half size one right below it, and the one in the vise under construction is the one that was traded for the lathe.

It took about a hundred hours to build the miniature, because every part has to be hand made from scratch. I finally finished it and delivered it to him, and then he brought the lathe for me the next day, like a mail order bride. That lathe had so much crud on it you could not even tell what it was. But some solvent and a parts washing brush fixed that. I uncovered a decal that said "Craftsman".

It was a model AA109.

Was it a fair trade? You bet! We both got what we wanted. I got more iron, and he might have got more value, but what is a few hours between good friends.

At home Kip had a 4 year old grandson pose with the rifle while they took some pictures and that kid was really "hamming" it up. When the picture taking was finished, Kip went to get the rifle and that was not an option as far as the grandson was concerned. Kip had to pry his fingers off to get it back.

Shortly after I got the AA109 set up on display, my friend George from Brigham City brought me a box of lathe parts that someone had given to him. Apparently someone had taken it apart to paint it and then never reassembled it again. The main parts were there, but so many of the little parts had vanished, like gibs, half nut, handles, etc. etc. that it was no longer serviceable. It was a model 80. Just a newer version of the AA109. Most of the working parts are interchangeable. After sitting in the nurturing atmosphere of my workshop it began to grow those missing parts until it became functional again.

Both lathes are now on display. They would do machining, but not the way my new Jet does, so they can just sit there and amuse our visitors.

Birk