Great test, Brian! Needless to say, I'm pretty tickled with the results. While watching your progress on the Britnell carb, I've also been doing further testing with my original design, although I haven't posted anything.

I learned a couple of things.

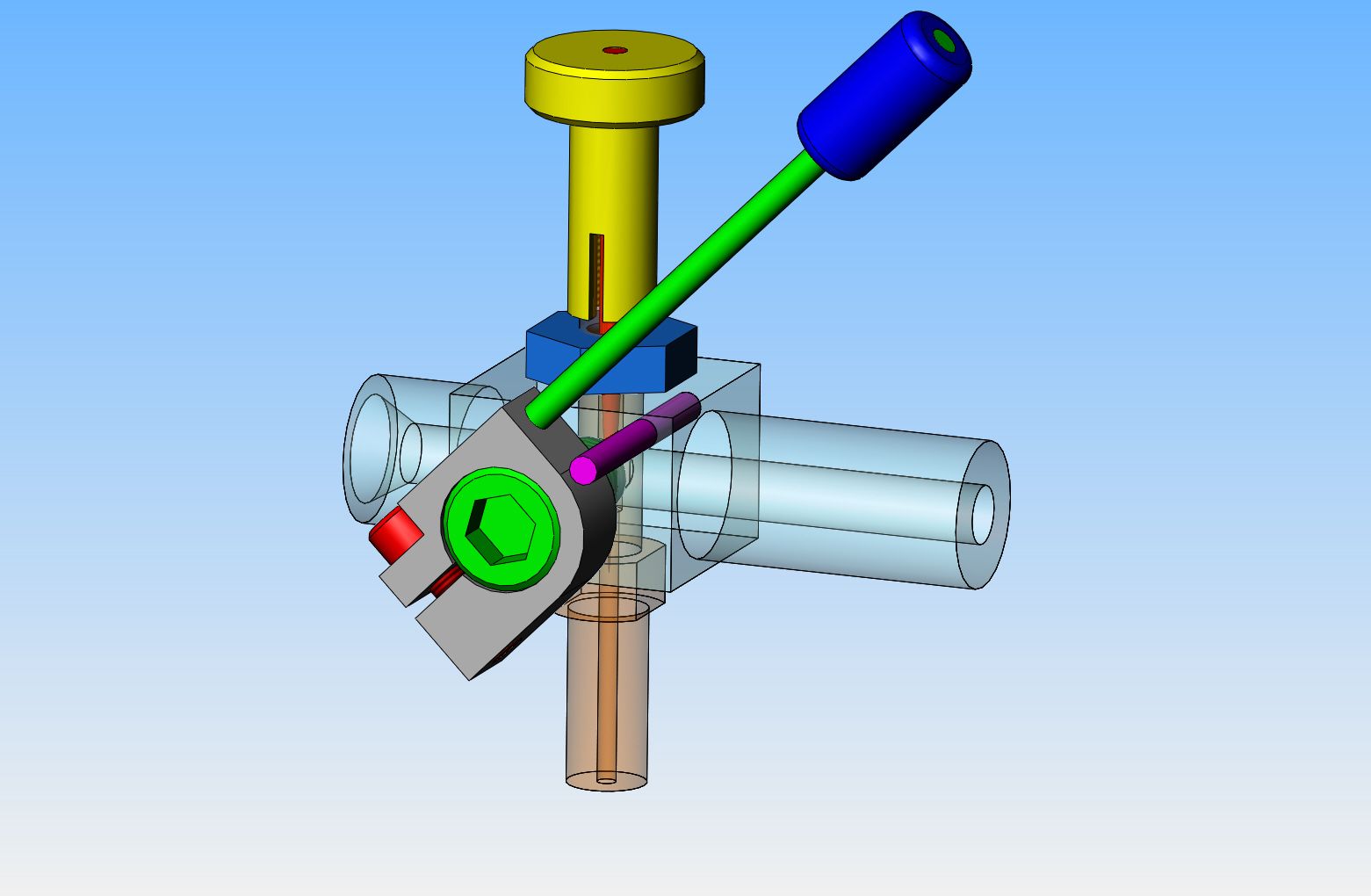

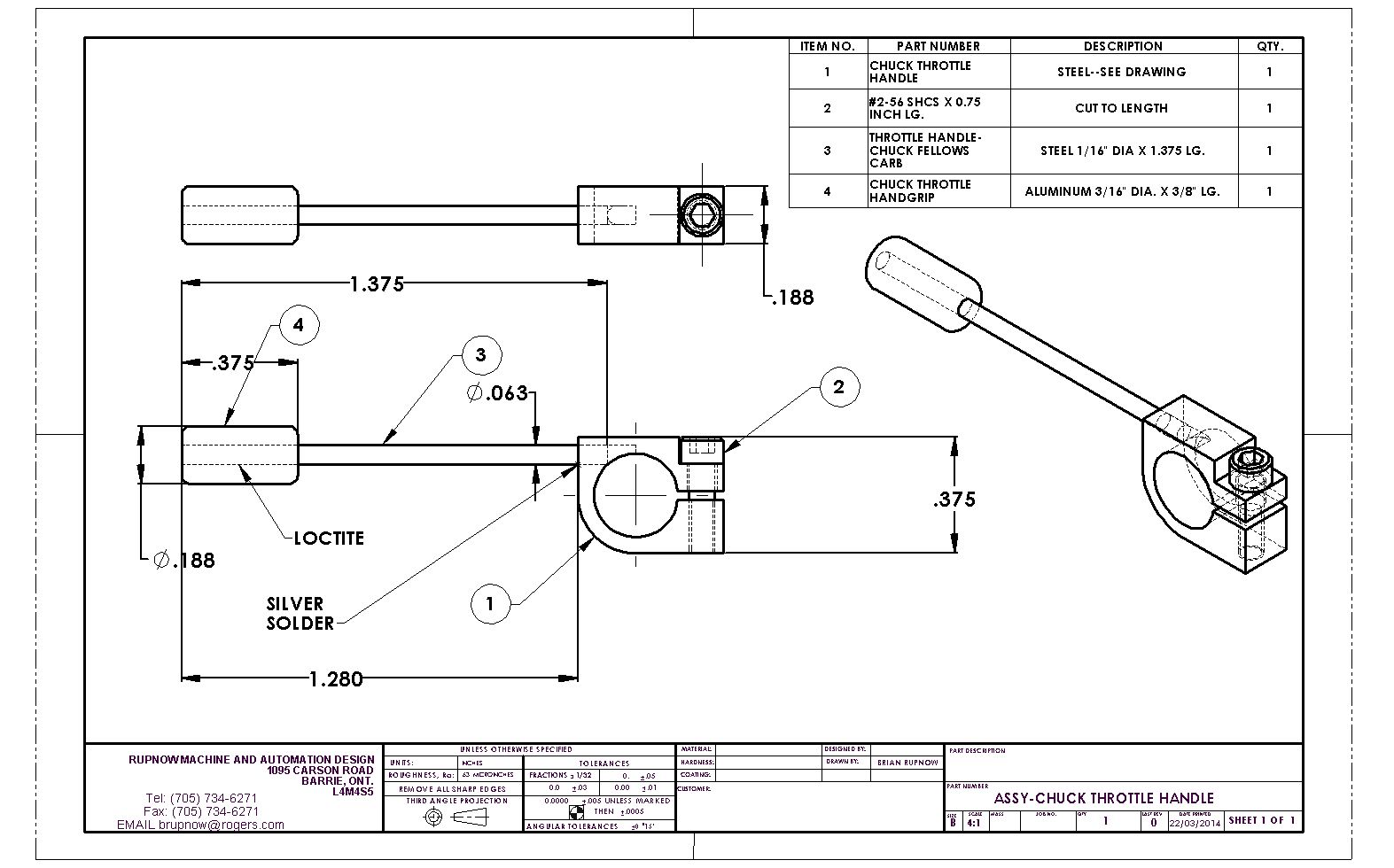

First, the rotational position of the needle valve assembly is very touchy. The fuel aperture into the air passage should point directly at or slightly in front of (away from the engine) the throttle screw. This makes a considerable difference in the way the carb performs.

Second, it turns out the problem I was having wasn't the fault of the carburetor, it was the ignition I was using. As you recall, I was testing the carburetor on my vertical single and I hadn't really shaken all the bugs out of the engine itself. So, with a proper working ignition installed, the results I'm getting are much better. I built another carburetor for the vertical single, sticking to my original design, but I made the venturi 5/32" instead of the original 1/8". I also used a 10-32 throttle screw instead of the 8-32. This carburetor works quite well and I'm happy with it.

I'm still using my first carburetor with the 1/8" venturi on my plumbing parts engine and it runs flawlessly. It will idle down to a very slow speed and never miss a lick.

So, in summary, I was a bit quick on the trigger to abandon my original design and your test seems to confirm my later results. I think both your carb and mine will satisfy most needs for slow running model engines.

Thanks for all the work you put in on this, particularly in documenting your build and in running the comparative tests!

Chuck