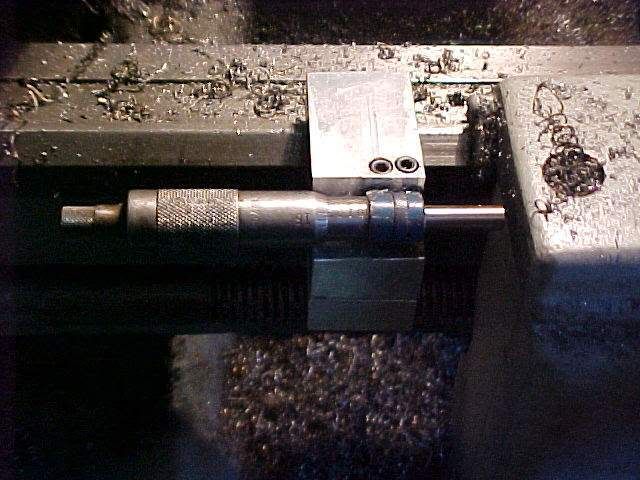

With all the suggestions for carriage stop, I might as well add mine. Made from a yard sale mic but with new mics at $9.00 it is not expensive and easy to make. Just hacksaw off the required piece and make the rest to fit your lathe.

I use it regularly to cut, bore or drill (with drill bit on tool post) to specified depth. Set the stop short of where you want to be, make the first cut and then measure and adjust the mic to the exact spot you want. Making repetitive cuts is a no brainer then.

If threading to a certain point and using the compound to advance the tool, you can adjust the mic after each cut to compensate for the right to left movement of the compound when you advanced it

No shiny paint in my shop, the tools get used.

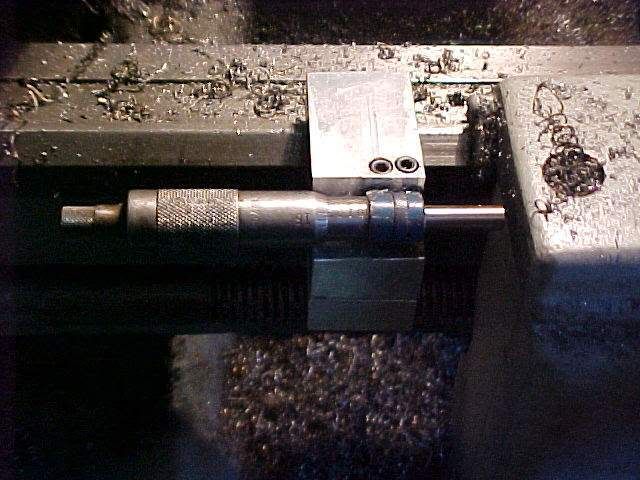

I use it regularly to cut, bore or drill (with drill bit on tool post) to specified depth. Set the stop short of where you want to be, make the first cut and then measure and adjust the mic to the exact spot you want. Making repetitive cuts is a no brainer then.

If threading to a certain point and using the compound to advance the tool, you can adjust the mic after each cut to compensate for the right to left movement of the compound when you advanced it

No shiny paint in my shop, the tools get used.