Hi Bob,

My, My you have been busy, well done that man.

The engine looks terrific and I am eagerly awaiting the first run.

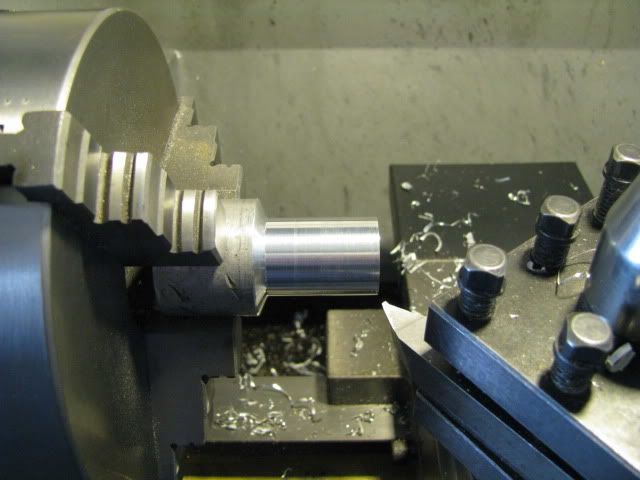

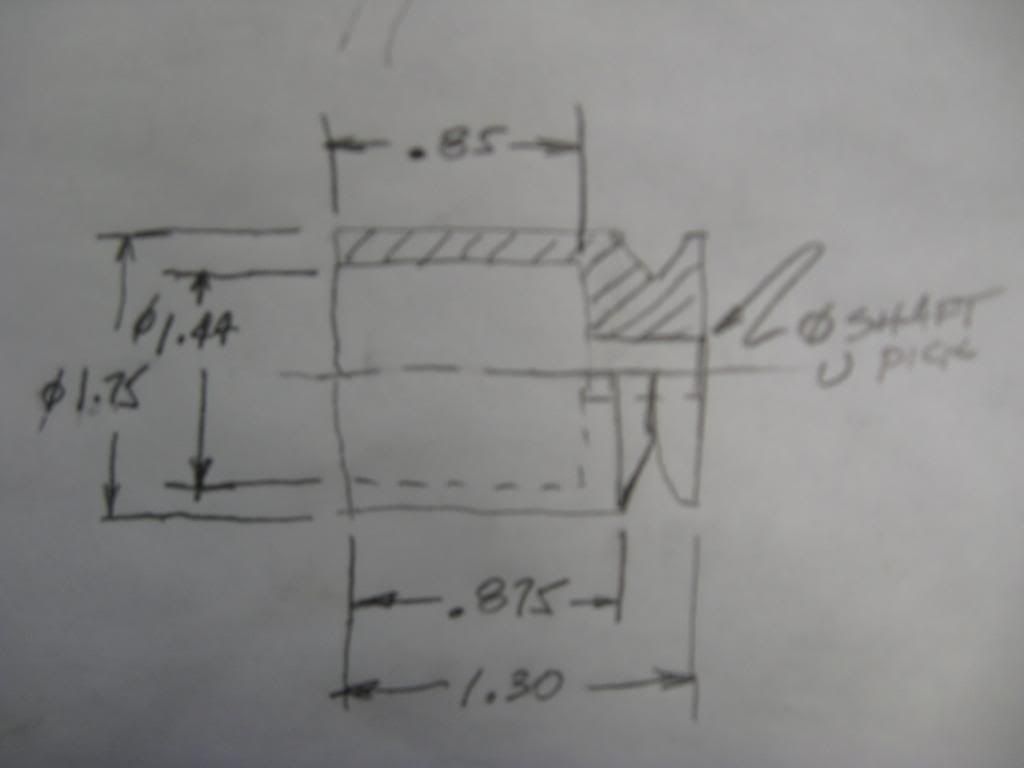

I would like to ask one question though.... how is your prop driver (back nut) connected to the crank shaft, it looks like you have threaded it?

If this is so, and the final front spinner nut is also threaded on to the same shaft, thus clamping the prop between the 2 then there is a risk (especially if you are using an electric starter) that the front spinner will slacken slightly under the engine compression, which would leave the prop, and both nuts capable of unscrewing from the shaft when the engine is running.  NOT RECOMMENDED.

Normally, when a starter is used a separate spinner is fitted (with the front shaft nut inside it) which envelopes the prop hub, thus the force from the starter is applied more to the prop hub than to the spinner nut.

This would not cause the same, potential, loosening and is therefore a much safer option.

Having said that, it is not usually recommended that you start compression ignition engines using an electric starter, the forces are just so much greater than with a GLOW PLUG engine, which has much lower, and constant compression, and can lead to con rod damage or worse.

If you must use a spinner nut and the electric start, then might I suggest that you also use a standard prop nut to clamp the prop then fit the spinner nut as a lock nut.

Remember, make sure you run your drill in REVERSE when using it as a starter.... otherwise you could be there all day

;D ;D

I trust you will consider this as a safety warning.

Congratulations on a great build.

best regards