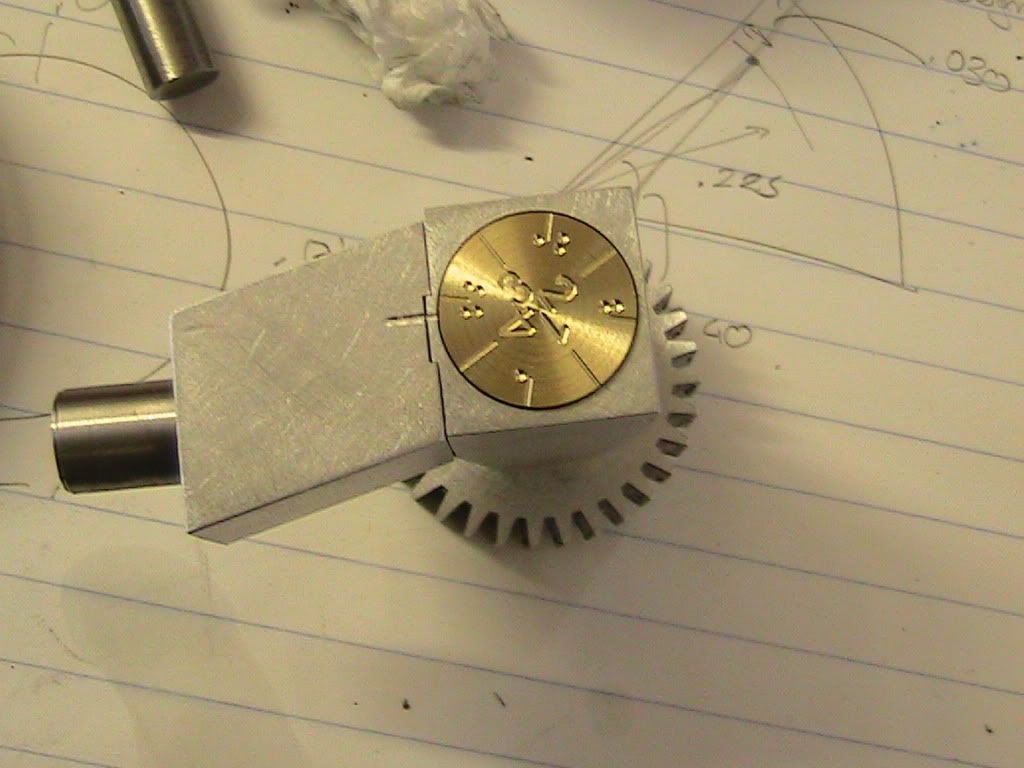

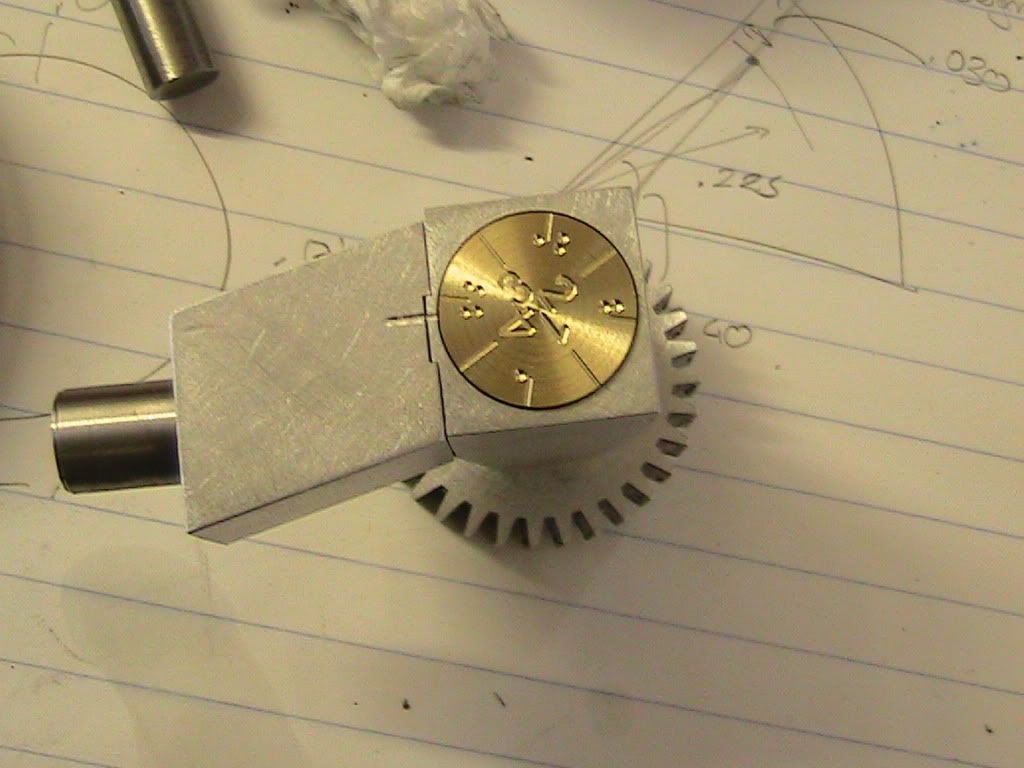

And this is how the almost final product looks.

I may have to paint the dial and the mark on the holder for visibility...

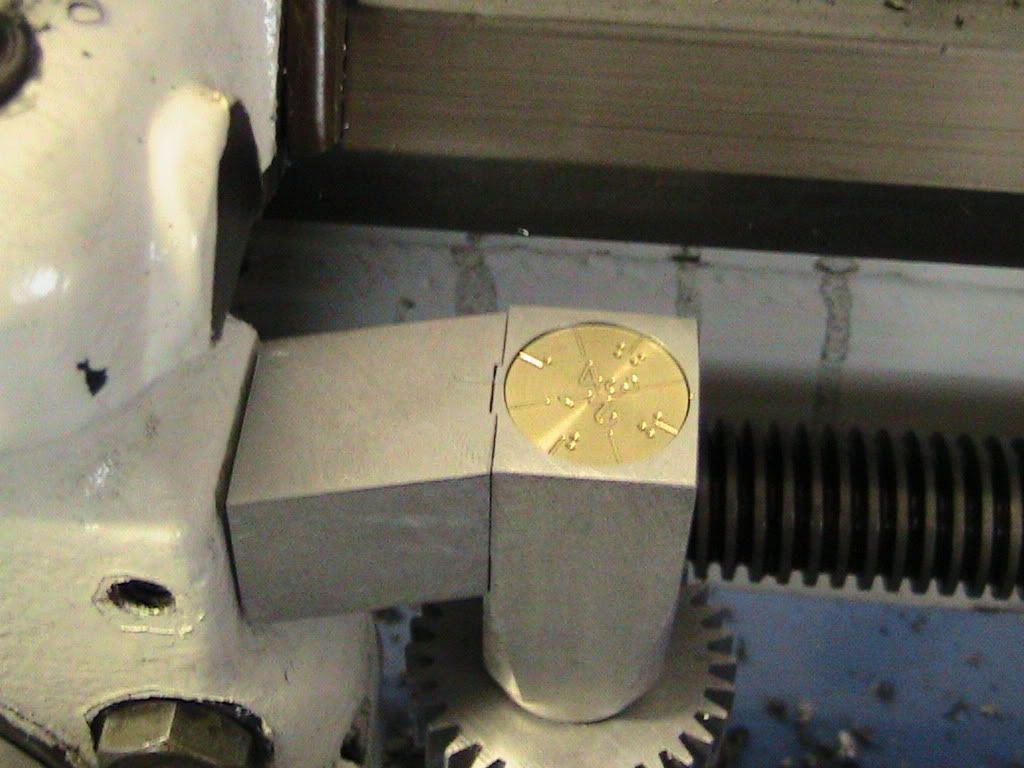

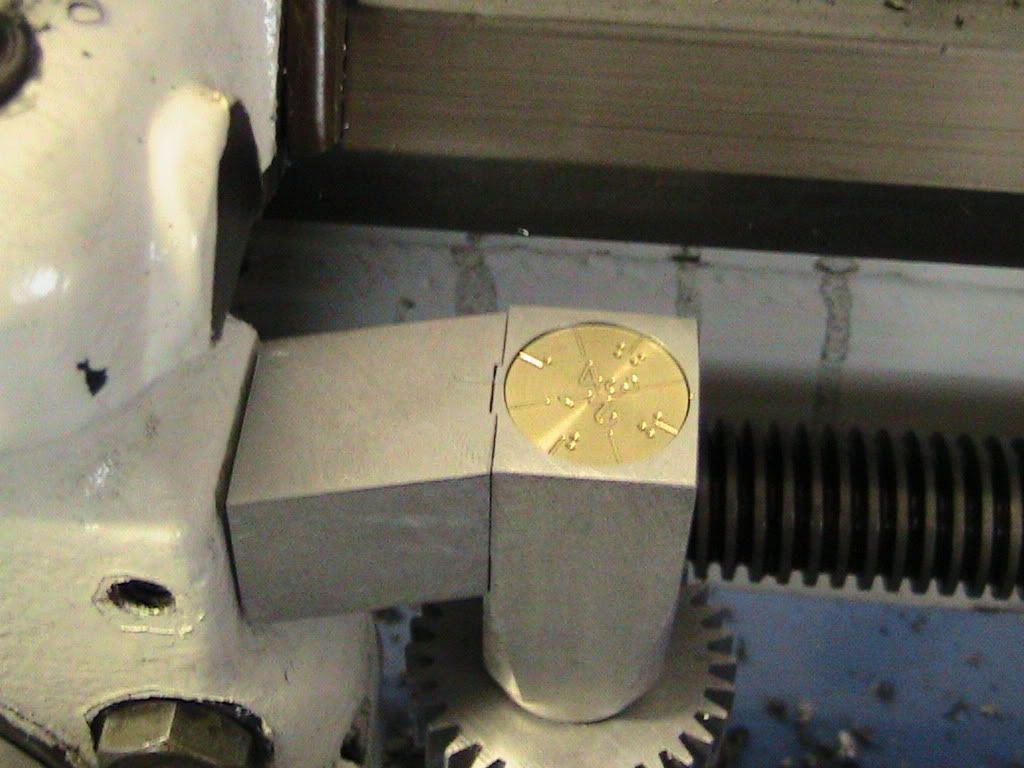

Test fit on the 10K...

and another view...

So tomorrow I'll see if I can find a spring washer to do the mounting as per john's (Bogs') suggestion. It may mean that I should put a (V?) groove on the steel round pin that goes into the casting also...

I still have to reduce a tad the length of the gear teeth, make a housing for the gear, and then lock it in place with blue loctite (as per Marv)

Any suggestions on painting the engravings? I'll paint, let it set, and then scratch the paint off of the face (but not from the engravings) with some fine grit sandpaper... any suggestions on colors? :big:

take care,

Tom in MA

I may have to paint the dial and the mark on the holder for visibility...

Test fit on the 10K...

and another view...

So tomorrow I'll see if I can find a spring washer to do the mounting as per john's (Bogs') suggestion. It may mean that I should put a (V?) groove on the steel round pin that goes into the casting also...

I still have to reduce a tad the length of the gear teeth, make a housing for the gear, and then lock it in place with blue loctite (as per Marv)

Any suggestions on painting the engravings? I'll paint, let it set, and then scratch the paint off of the face (but not from the engravings) with some fine grit sandpaper... any suggestions on colors? :big:

take care,

Tom in MA