Philjoe5

Well-Known Member

- Joined

- Jul 12, 2007

- Messages

- 1,727

- Reaction score

- 321

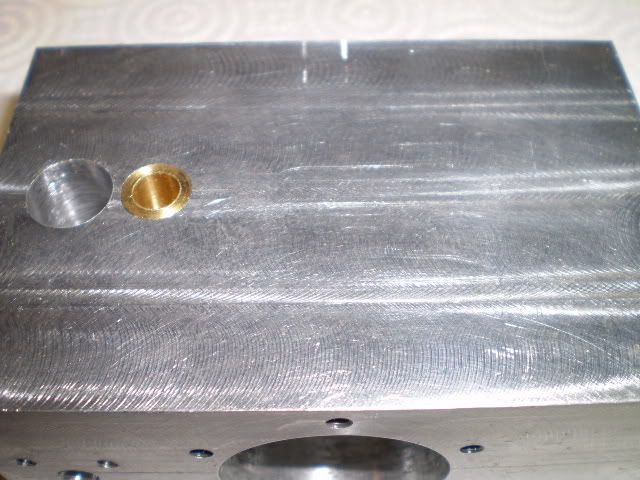

Last evening I milled a piece of steel of unknown alloy. I used an inexpensive but new end mill of 1 diameter. I obtained this surface finish, which, while appealing to the artist in me, seems fairly coarse. I was taking light cuts of maybe 0.020 at not more than 200-300 rpm. I did not experience any unusual vibration during this operation.

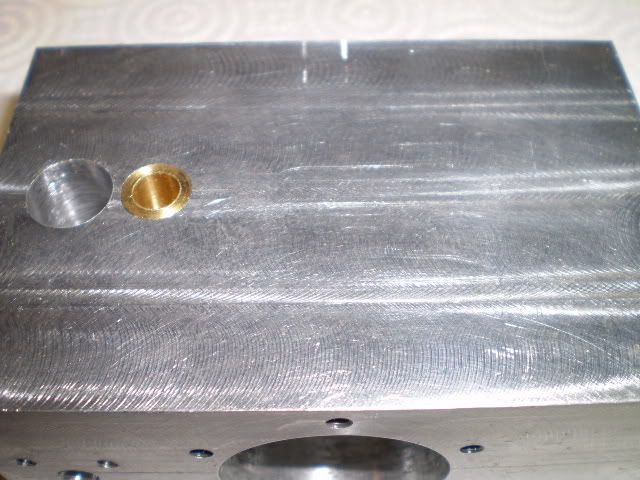

A few days ago I milled some 7000 series aluminum using the same setup and obtained a surface thats quite smooth

Am I seeing the consequence of a steel alloy that doesnt machine well or might there be some machine issues I should check? Any comments or advice appreciated,

Cheers,

Phil

A few days ago I milled some 7000 series aluminum using the same setup and obtained a surface thats quite smooth

Am I seeing the consequence of a steel alloy that doesnt machine well or might there be some machine issues I should check? Any comments or advice appreciated,

Cheers,

Phil