ChooChooMike

Well-Known Member

- Joined

- Jan 5, 2008

- Messages

- 864

- Reaction score

- 13

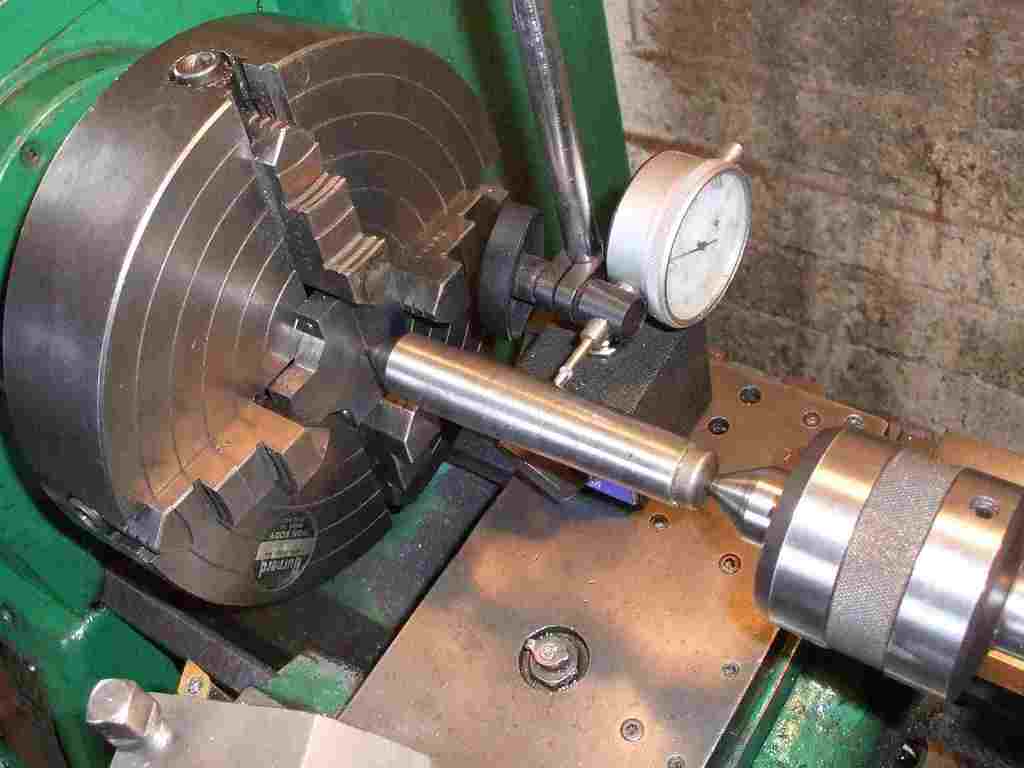

Has anyone made Kozo's wiggler/center test indicator from his Building the Shay book ?

If so, I'm curious as to what dimensions you used. His are in metric, so wanted to see what was used in place of those.

e.g. the rod diameter is 2mm = 0.0787. Guess you could substitute 1/16" or 3/32" for that or Enco has 2mm drill rod. Hmmm.

I realize the dimension aren't really that critical for what it does.

Here's 2 pages with few pictures :

http://www.thms.tedatum.com/PenA3/HTML/PA3_journals.html

http://www.thms.tedatum.com/shop16.html

If so, I'm curious as to what dimensions you used. His are in metric, so wanted to see what was used in place of those.

e.g. the rod diameter is 2mm = 0.0787. Guess you could substitute 1/16" or 3/32" for that or Enco has 2mm drill rod. Hmmm.

I realize the dimension aren't really that critical for what it does.

Here's 2 pages with few pictures :

http://www.thms.tedatum.com/PenA3/HTML/PA3_journals.html

http://www.thms.tedatum.com/shop16.html