Thanks guys. Your positive comments mean a lot to me. Now that it actually works, I can clean it up a bit and start work on a return ball track.---Brian

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Jacobs Ladder---

- Thread starter Brian Rupnow

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

AussieJimG

Well-Known Member

- Joined

- Oct 17, 2010

- Messages

- 890

- Reaction score

- 118

Thank you Brian, an educational journey all the way. Can't wait to see what you will do next.

Jim

Jim

Brian, a novel idea taken to conclusion (well almost) - just love it.

Thanks for taking the time to share that.

Ken

Thanks for taking the time to share that.

Ken

- Joined

- Jan 30, 2011

- Messages

- 365

- Reaction score

- 72

Hi Brian,

I have to confess this is not my kind of project but I have been following it from the beginning and have enjoyed watching it grow. I admire your ingenuity and the thought that you have put in as well as the excellent way you have presented it. Looking forward to it's further development.

Have a good break and Best Wishes for the coming year

Ramon

I have to confess this is not my kind of project but I have been following it from the beginning and have enjoyed watching it grow. I admire your ingenuity and the thought that you have put in as well as the excellent way you have presented it. Looking forward to it's further development.

Have a good break and Best Wishes for the coming year

Ramon

- Joined

- Dec 2, 2008

- Messages

- 971

- Reaction score

- 8

Brian

A very interesting mechanism and a lot of lessons learned. The problems with the connecting link reversing would have trapped me too and the simple solution of an elongated hole at one end is a good one to remember. The trouble that you had with the chain links jumping and the fix of moving the drive to the bottom shaft had me puzzled. I had to have an explanation for the improvement so I spent some time thinking. (what's that burning smell?) Here is my theory, others may think differently.

When you were driving the top sprocket, the top chain pulls tight and any slack in the chain causes the bottom side to droop away from the sprocket, reducing the effective number of sprocket teeth engaged allowing the chain to climb out.

When you drive the bottom sprocket, the bottom chain is pulled tight and the slack in the top chain droops to the inside of the loop, increasing the wrap on the the drive sprocket.

The key here is not the fact that one sprocket is higher than the other. The critical factor is that the droop in the chain must be on the top where it closes the loop and not on the bottom where it opens the loop.

If there are any different theories out there, speak up! I like to have a reason for things like this.

Jerry

A very interesting mechanism and a lot of lessons learned. The problems with the connecting link reversing would have trapped me too and the simple solution of an elongated hole at one end is a good one to remember. The trouble that you had with the chain links jumping and the fix of moving the drive to the bottom shaft had me puzzled. I had to have an explanation for the improvement so I spent some time thinking. (what's that burning smell?) Here is my theory, others may think differently.

When you were driving the top sprocket, the top chain pulls tight and any slack in the chain causes the bottom side to droop away from the sprocket, reducing the effective number of sprocket teeth engaged allowing the chain to climb out.

When you drive the bottom sprocket, the bottom chain is pulled tight and the slack in the top chain droops to the inside of the loop, increasing the wrap on the the drive sprocket.

The key here is not the fact that one sprocket is higher than the other. The critical factor is that the droop in the chain must be on the top where it closes the loop and not on the bottom where it opens the loop.

If there are any different theories out there, speak up! I like to have a reason for things like this.

Jerry

Shows your thinking Jerry. The fact that I removed one link from the chain was a big help too. ;D ;D

Christmas is over, all the relatives have returned home, and I got to play in my shop a bit this afternon. The Jacobs ladder runs successfuly when driven by my "Overcrank Single" air/steam engine. I however, am having a very difficult time getting am "in focus" movie of it. My camera instructions say to hold the button half way down to let the auto focus work before pushing it all the way down to take a picture. That seems to work fine for still shots, but doesn't seem to work worth a darn when I'm making a video. I will talk to the Cannon camera people when the holidays are over and get that sorted out. I may try the Jacobs Ladder with my horizontal twin engine tomorrow and see if the action smooths out any--its a bit jerky when driven by the Overcrank Single. At any tate, another milestone has been reached, as I now know that one of my air/steam engines has enough power to run things.

Success!!! I have figured out the mystery of my camera (Read the instruction booklet) and changed engine over to my Horizontal Twin to run the Jacobs ladder. Its working real slick now. And yes, you will hear me contradict myself---I can't honestly remember if it was 3 or 4 years ago that I built my horizontal twin engine---(I say both in the video). Now I can start work on my ball return track.

Slowly, and not too surely, my ball return is progressing. I'm making it up as I go along here, but this first leg of the return track seems to work okay.---At least any balls dropped in at the top end do fall cleanly and quickly out through the hole in the side. ;D ;D

Its not very often that I think I'd like a power feed on my mill table, but it would have been nice to have one today!!! I'm building the second part of my return ball track, and that slot is about 10" long x 1/4" deep x 3/4" wide. I feed .030" on the vertical axis bfore each cut, and deepen it another .030" when I reverse directions, so I'm cutting while travelling both ways. With a 3/8" end mill, daamn, thats a lot of cranking!!!!

chuck foster

Well-Known Member

- Joined

- Jul 11, 2007

- Messages

- 704

- Reaction score

- 2

i know it is too late now but you should try a roughing end mill, you would have been able to cut that slot in 2 passes.

i tried a roughing end mill for the first time about a month ago and man oh man do they cut

i had a 1/2" roughing end mill in my mill and took a cut .250" deep (in aluminum), the cutter was spinning 1800 rpm's and

as fast as i could crank the work into the cutter it just kept cutting.

the swarf was just flying.

just a thought.............all be it a late thought

chuck

i tried a roughing end mill for the first time about a month ago and man oh man do they cut

i had a 1/2" roughing end mill in my mill and took a cut .250" deep (in aluminum), the cutter was spinning 1800 rpm's and

as fast as i could crank the work into the cutter it just kept cutting.

the swarf was just flying.

just a thought.............all be it a late thought

chuck

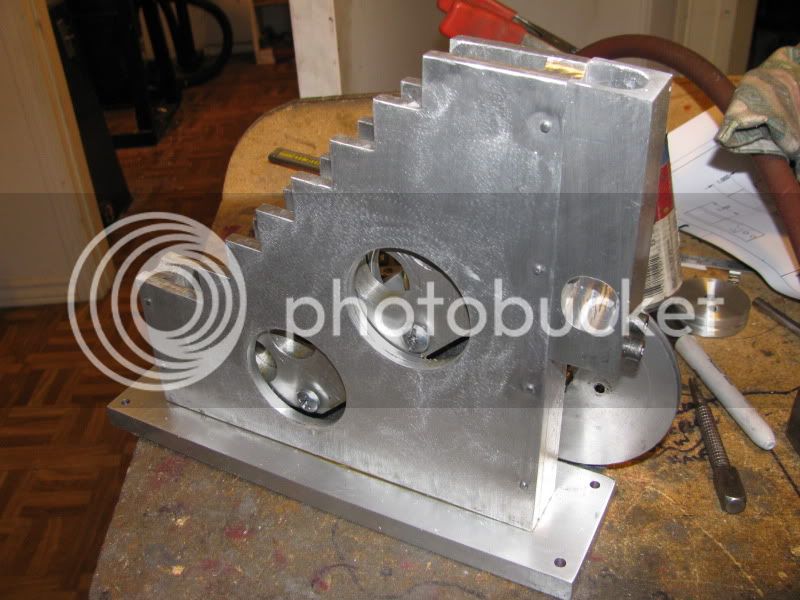

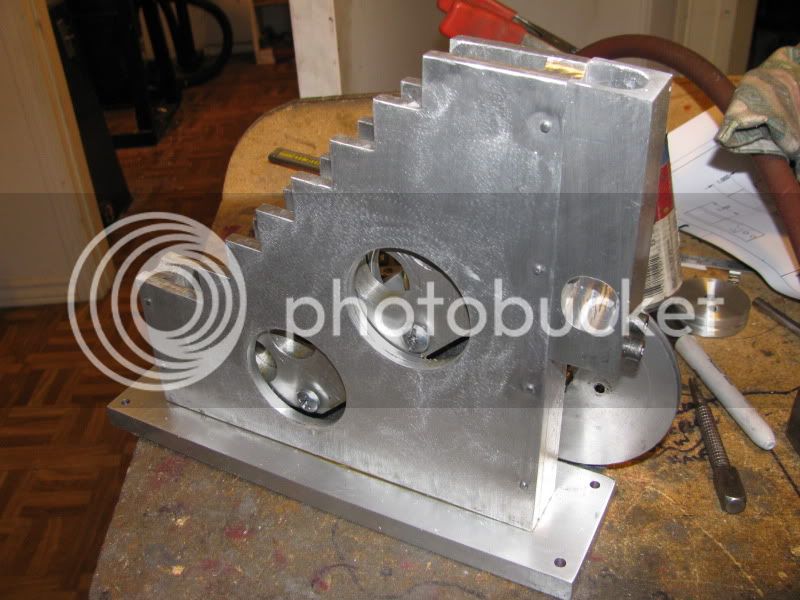

Rotary tables are a GOOD thing to have!!!!

And yes, the ball does return all the way to the first step!!! Now, to build a few brackets to hang my ramp on-----

Similar threads

- Replies

- 77

- Views

- 24K