camm-1

Well-Known Member

- Joined

- Feb 15, 2012

- Messages

- 109

- Reaction score

- 58

Hi

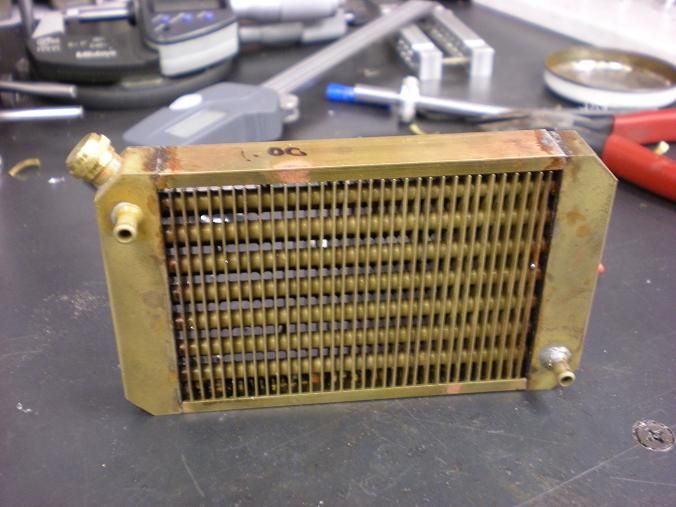

I would like to know how do you guys who can make so good looking

radiators do???

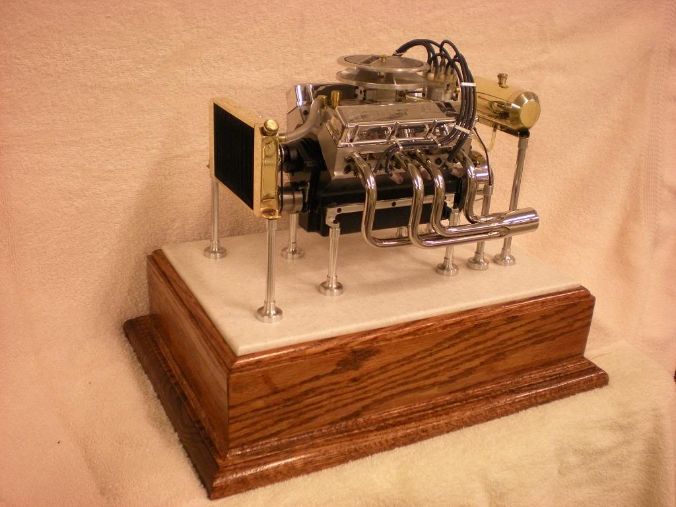

Like this for example (mr gbritnell´s ford)

http://www.youtube.com/watch?feature=player_embedded&v=lfTGrYdp_BI

Happy New Year!!

Ove

I would like to know how do you guys who can make so good looking

radiators do???

Like this for example (mr gbritnell´s ford)

http://www.youtube.com/watch?feature=player_embedded&v=lfTGrYdp_BI

Happy New Year!!

Ove