hi guys. a few months back i posted a thread asking about making a speed reducer for my mini lathe. some guys recommended using poly-v/ micro-v belts, so i ordered some up and got them a while ago. i also bought some material and have made a part once in a while and have finally got something going. pictures are worth a thousand words, so here you go.

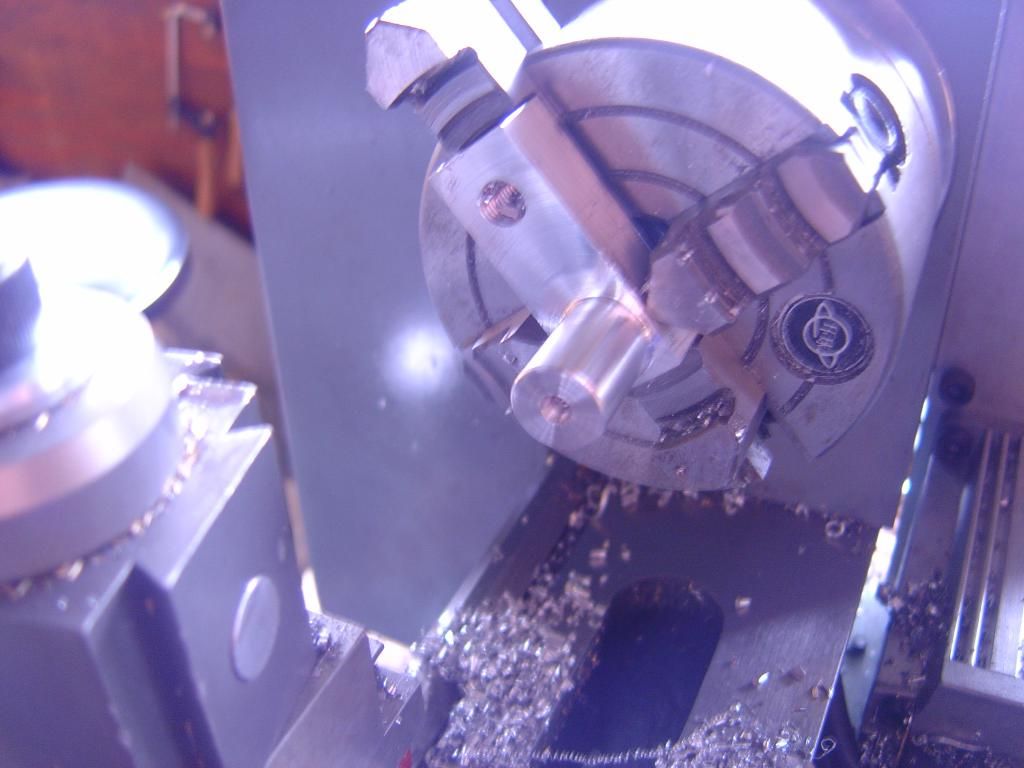

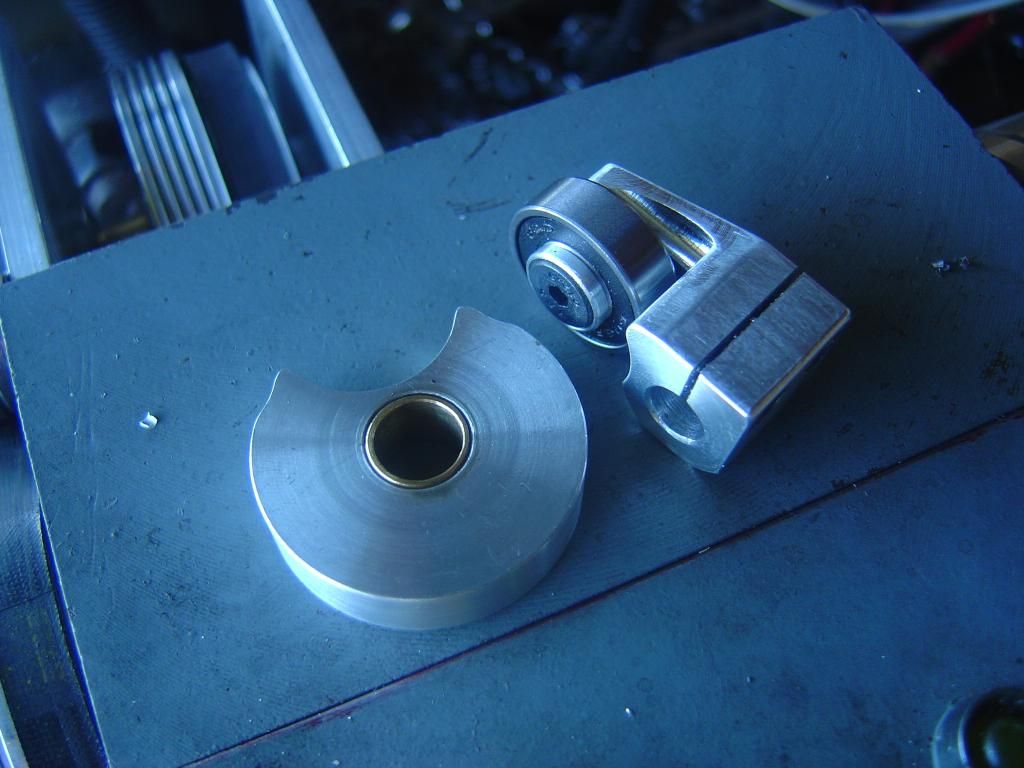

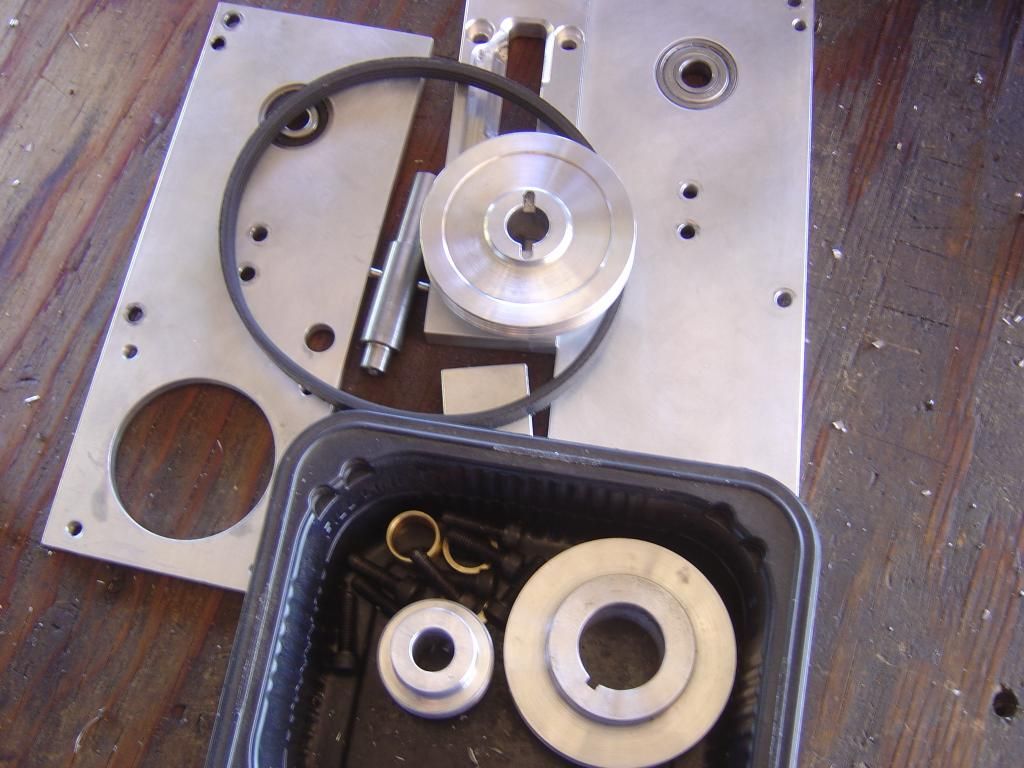

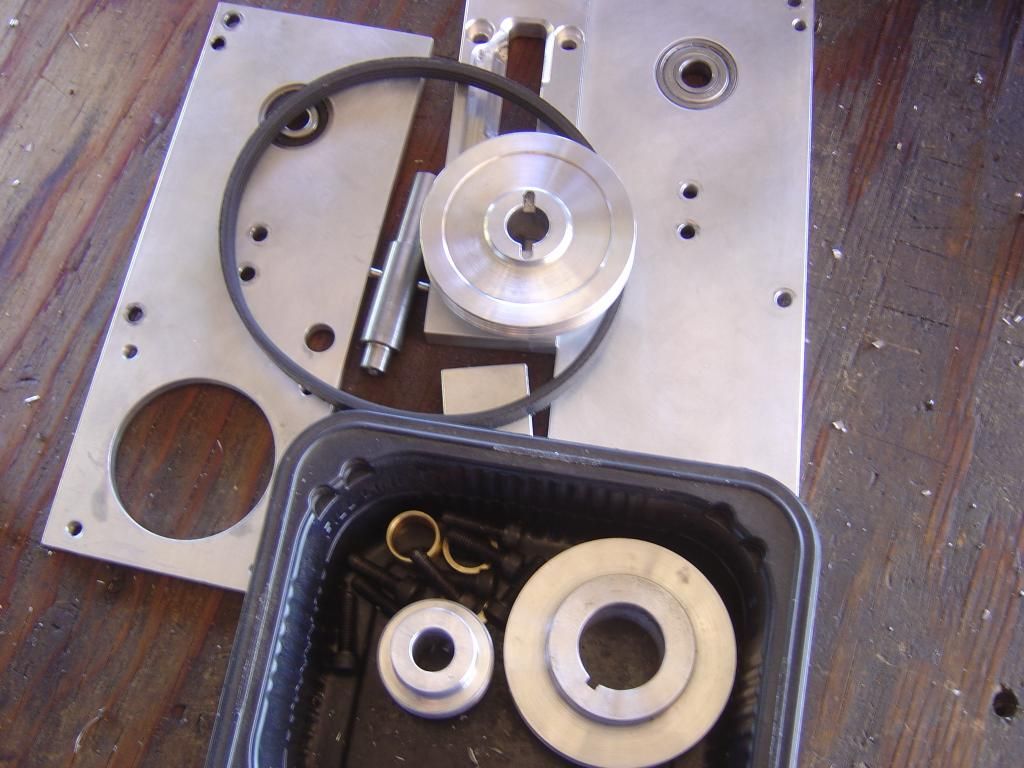

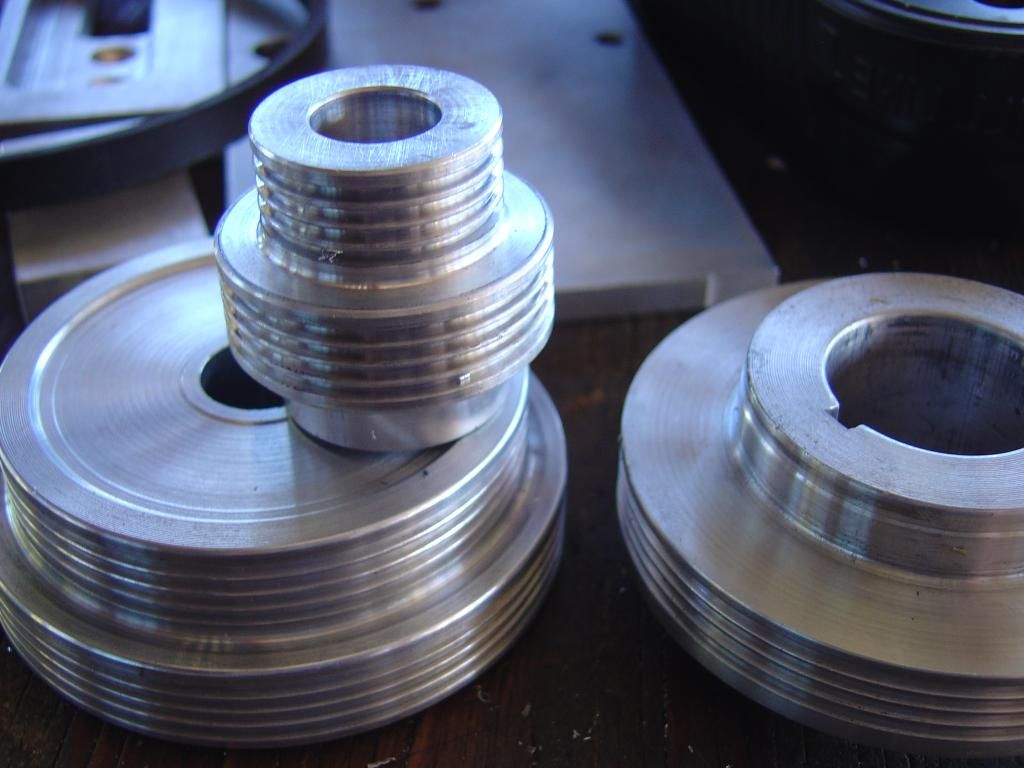

some of the parts

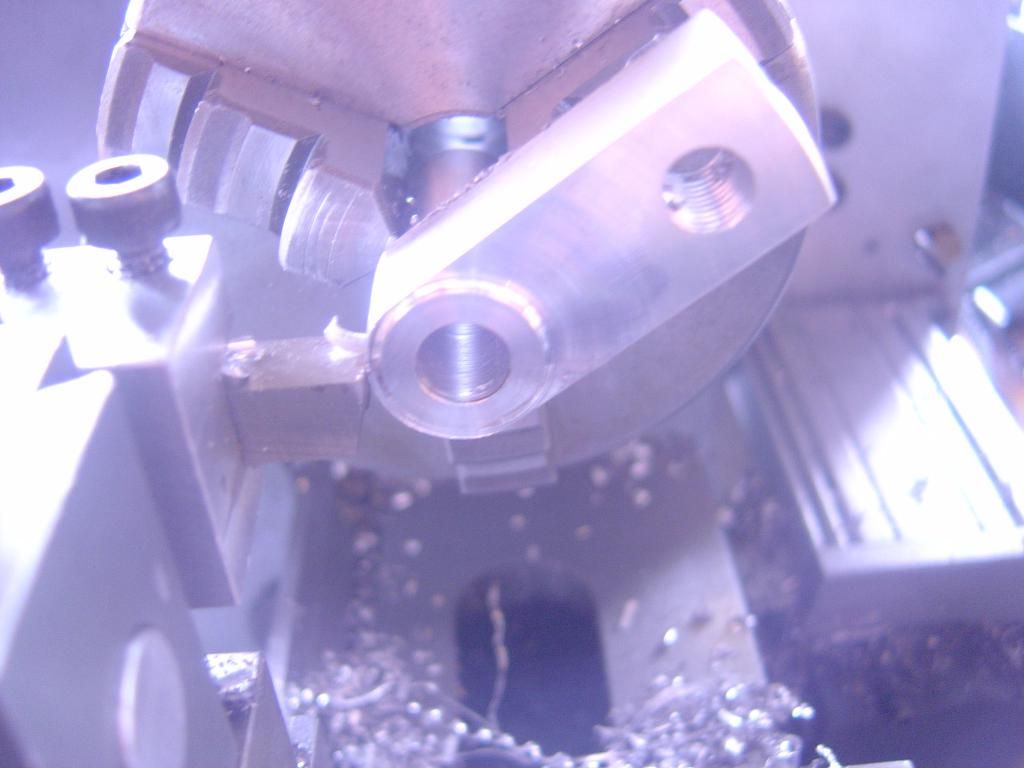

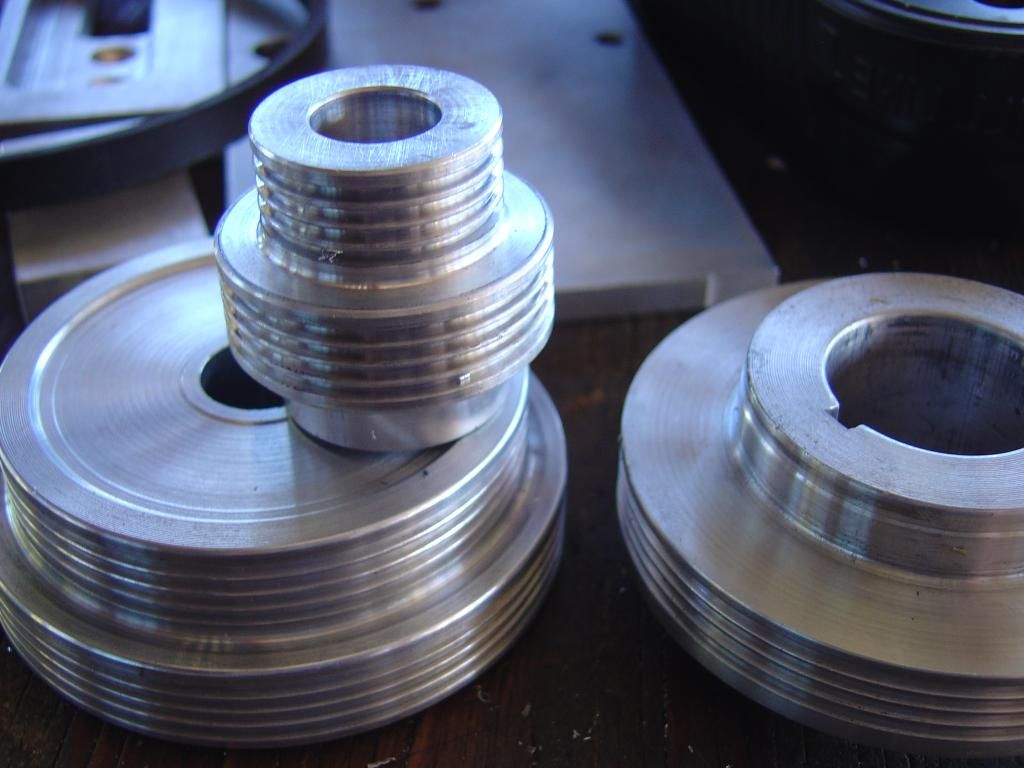

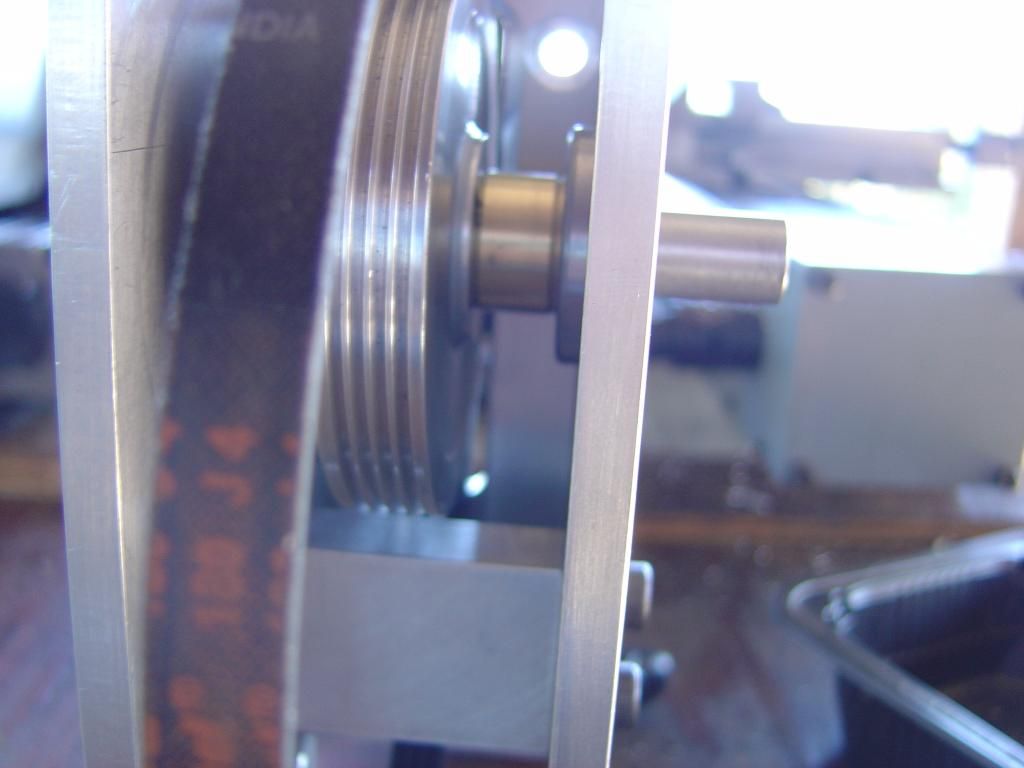

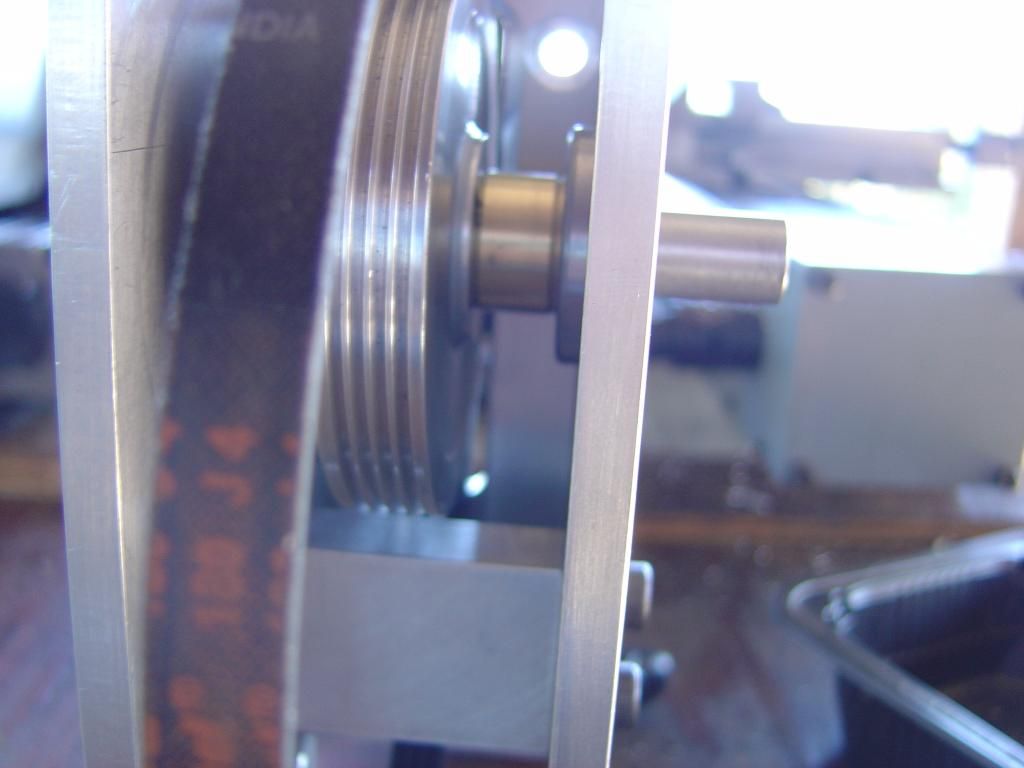

all the pulleys

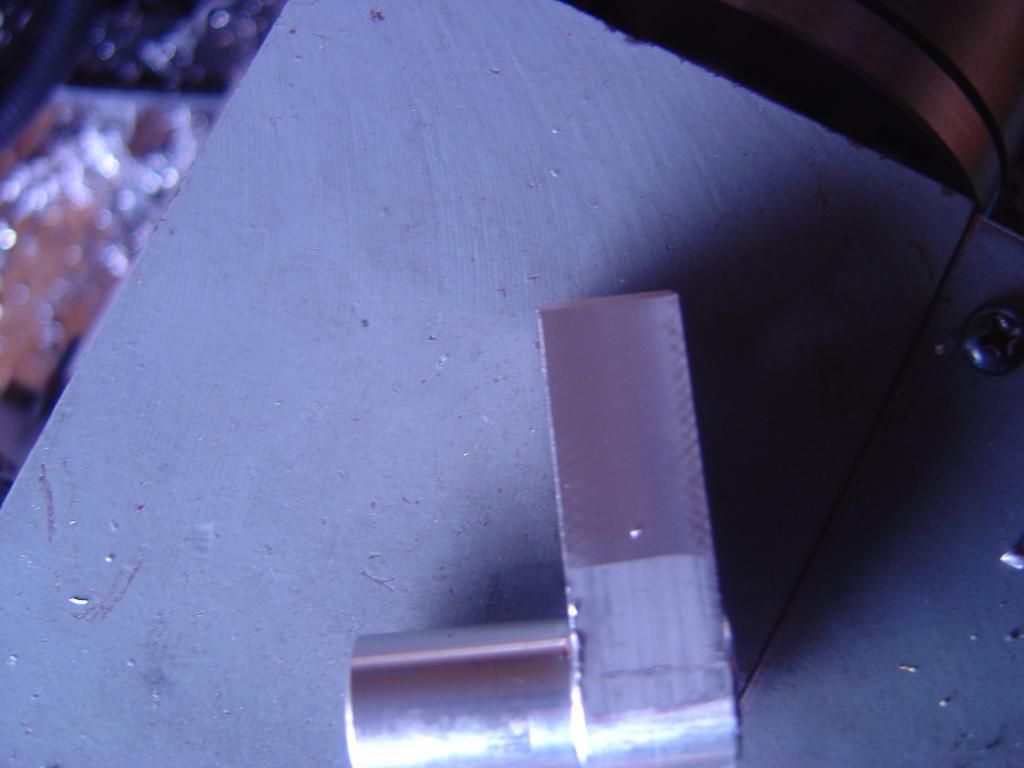

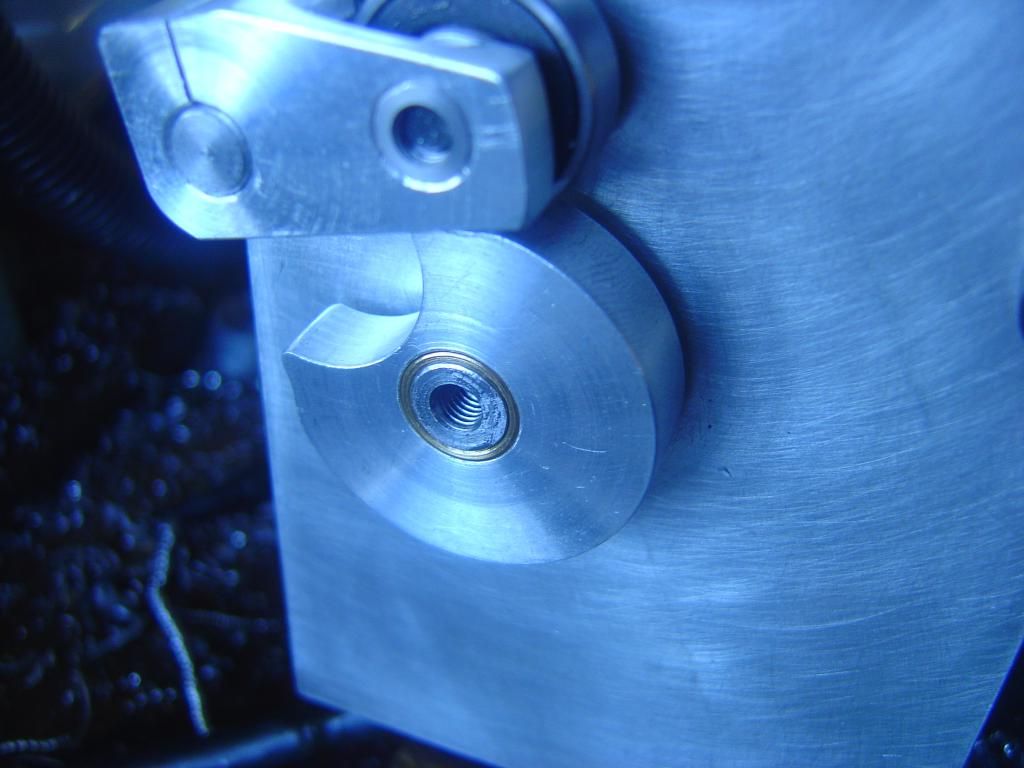

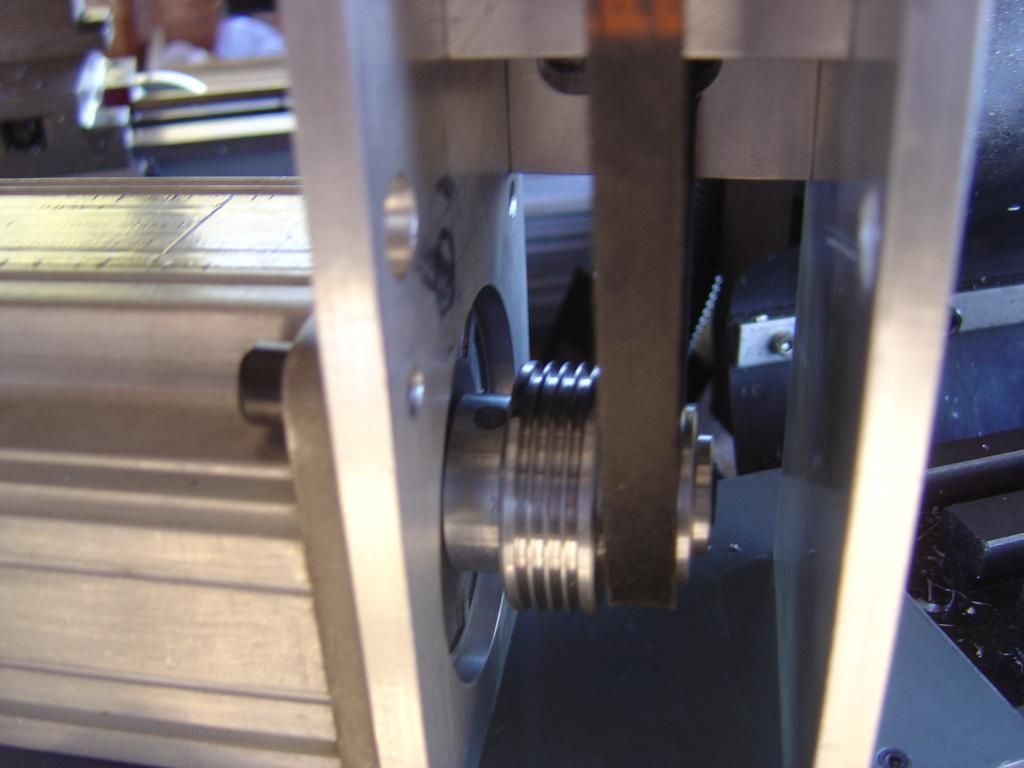

here is the cutting tool i made for the job.

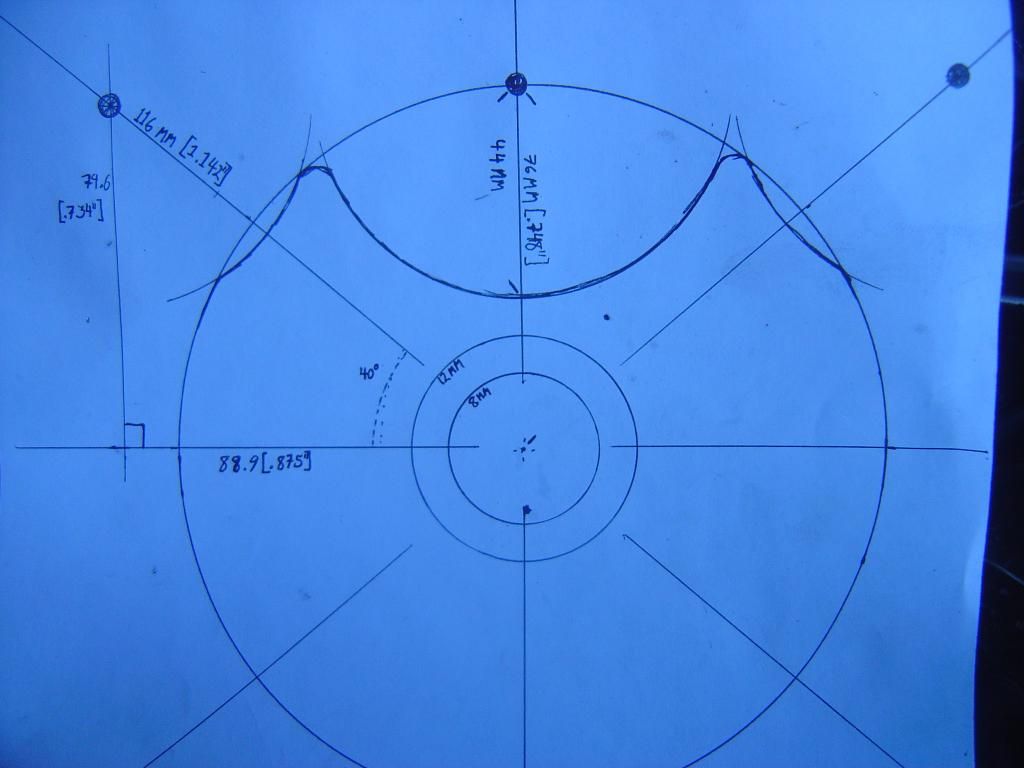

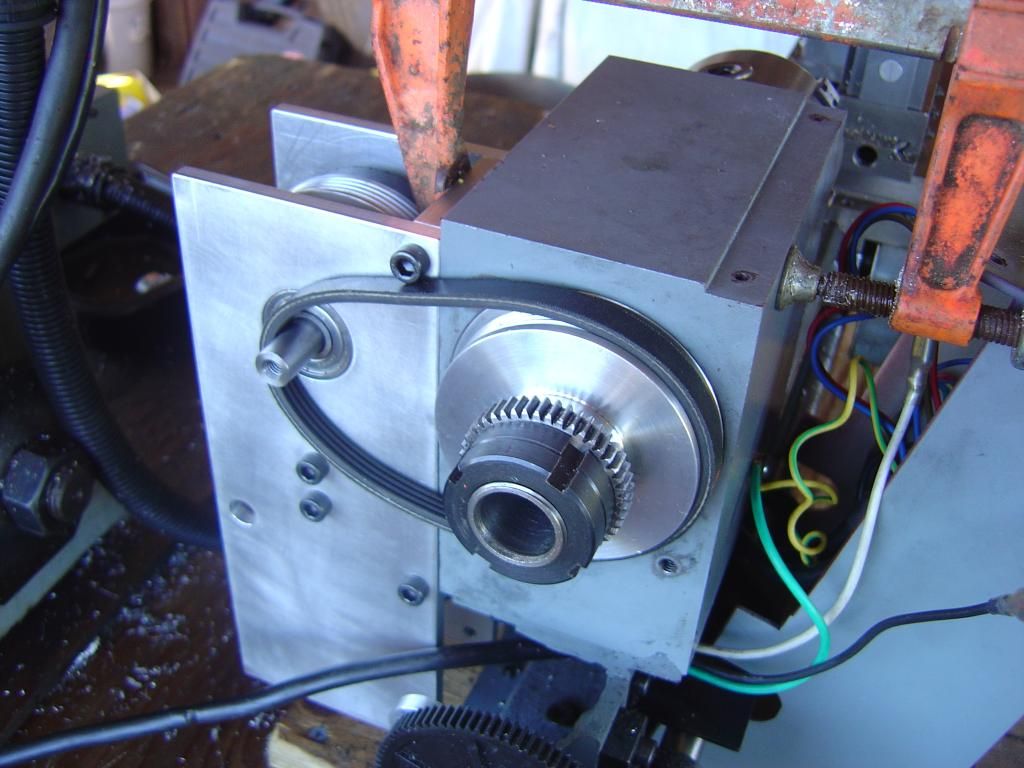

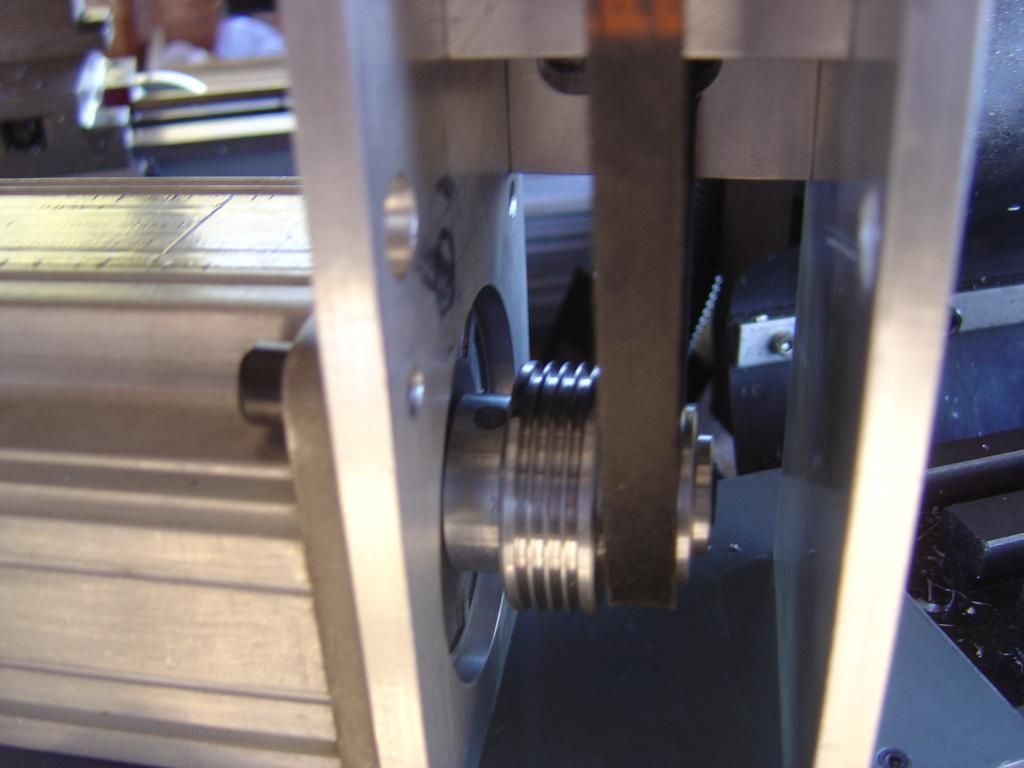

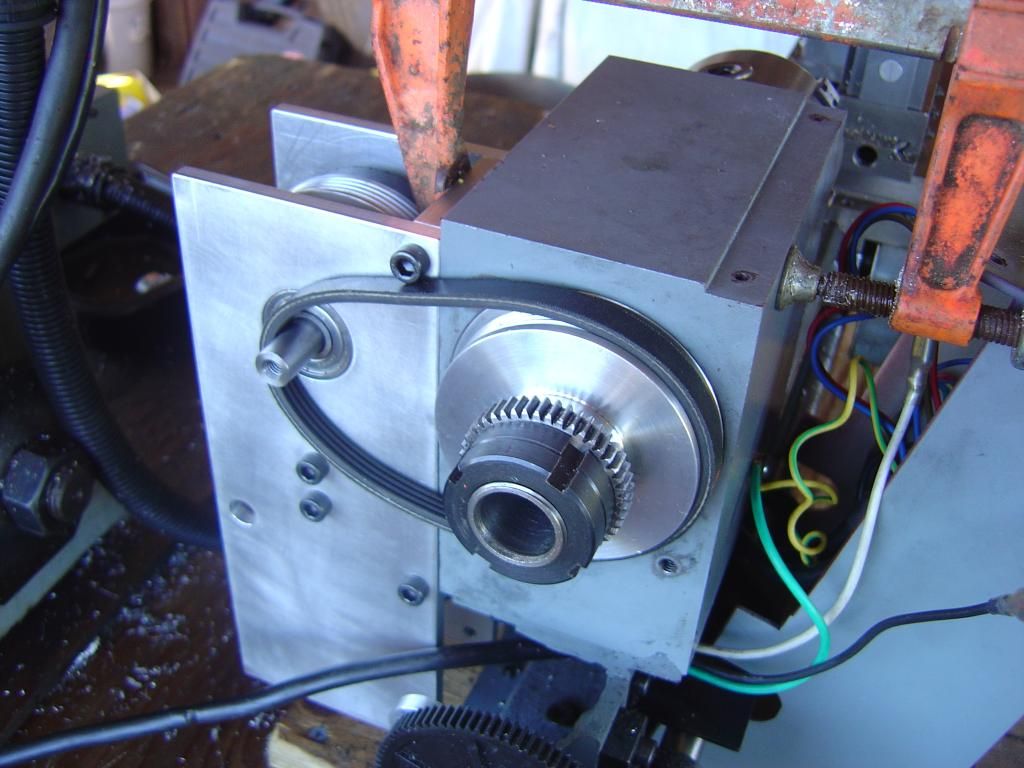

mocked up

minimum speed in low range is 27rpm, max is 825rpm , with significant torque. will be good for threading and tapping. ratio from chuck to motor is about 7:1 (original belt is 2:1). to measure the speed i used a home made worm wheel and screw. timed how long it took to advance 310 teeth (the gear had some weird number and i just counted the tens to make it easy). it took over 11 minutes at low speed!

i still need to make proper tensioners for the belt. even with incorrect tension on the belts it has more usable power than before!

some of the parts

all the pulleys

here is the cutting tool i made for the job.

mocked up

minimum speed in low range is 27rpm, max is 825rpm , with significant torque. will be good for threading and tapping. ratio from chuck to motor is about 7:1 (original belt is 2:1). to measure the speed i used a home made worm wheel and screw. timed how long it took to advance 310 teeth (the gear had some weird number and i just counted the tens to make it easy). it took over 11 minutes at low speed!

i still need to make proper tensioners for the belt. even with incorrect tension on the belts it has more usable power than before!