Maryak

Well-Known Member

- Joined

- Sep 12, 2008

- Messages

- 4,990

- Reaction score

- 77

Dave & Pete,

Thanks guys :bow: :bow:

After my problems with Firefox 4 and photobucket I finally uploaded a couple of piccys.

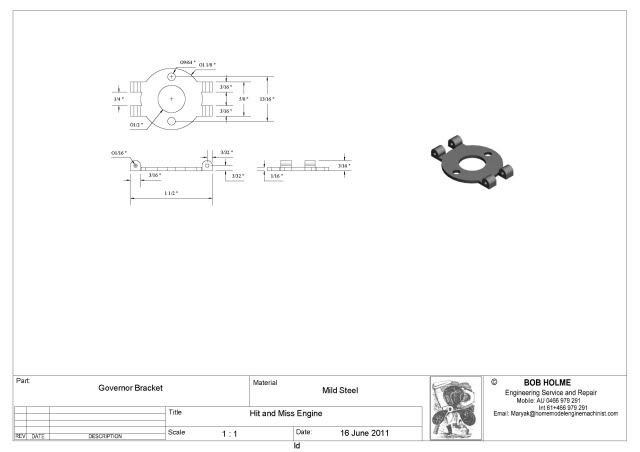

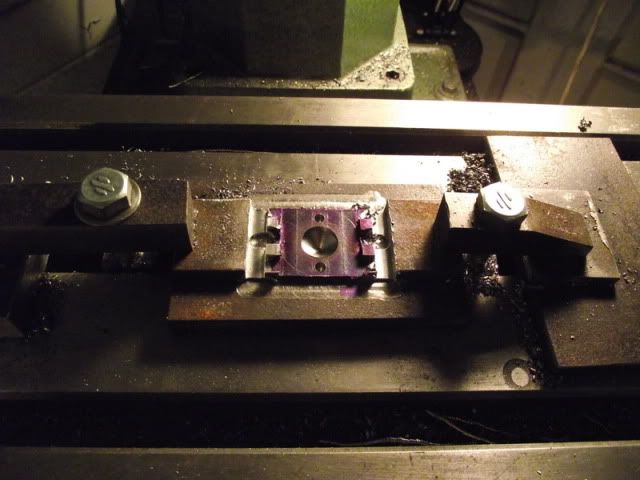

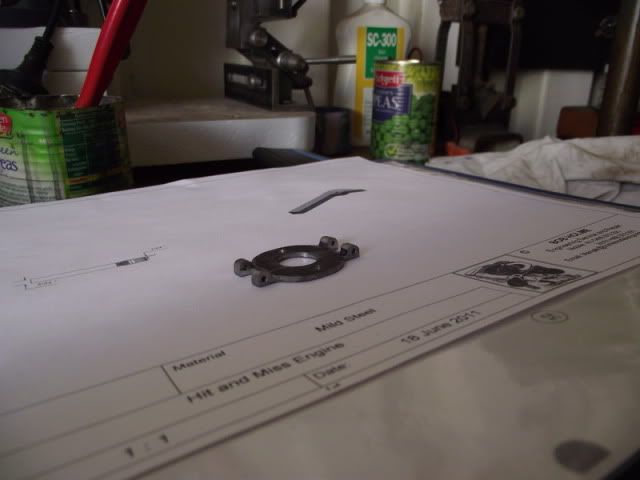

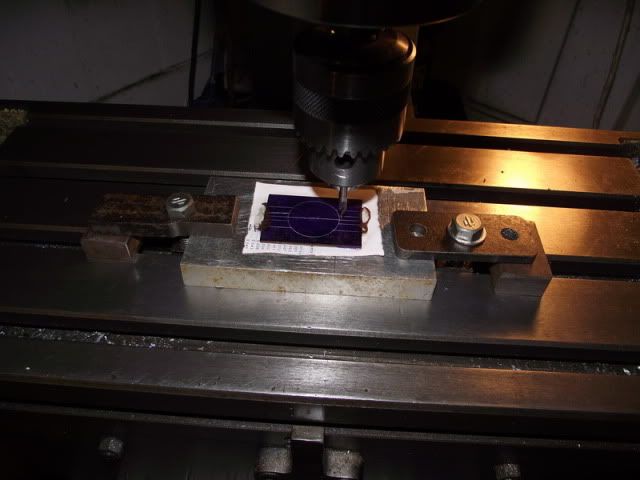

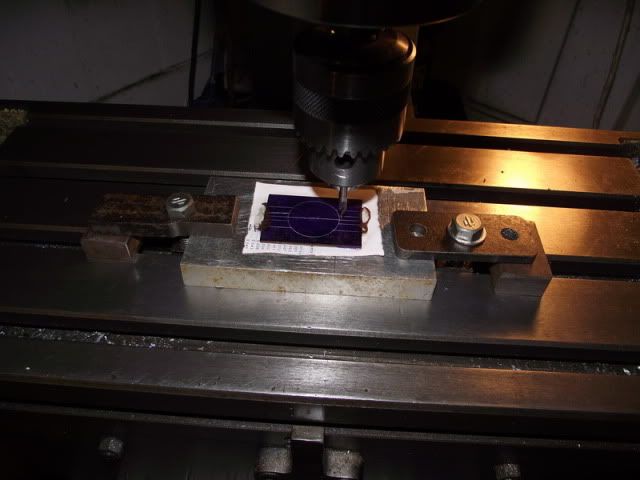

The governor bracket.

A couple of hacks and a bit of filing should see me ready to fold the arms to make the hinges for the weights and arms.

Best Regards

Bob

Thanks guys :bow: :bow:

After my problems with Firefox 4 and photobucket I finally uploaded a couple of piccys.

The governor bracket.

A couple of hacks and a bit of filing should see me ready to fold the arms to make the hinges for the weights and arms.

Best Regards

Bob