PeterB

Well-Known Member

- Joined

- Mar 2, 2012

- Messages

- 53

- Reaction score

- 14

Please, help me, I need a brain :-\

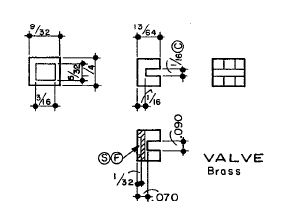

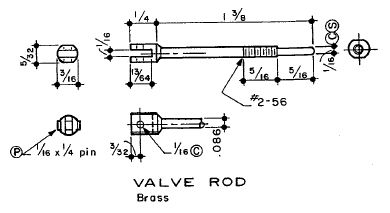

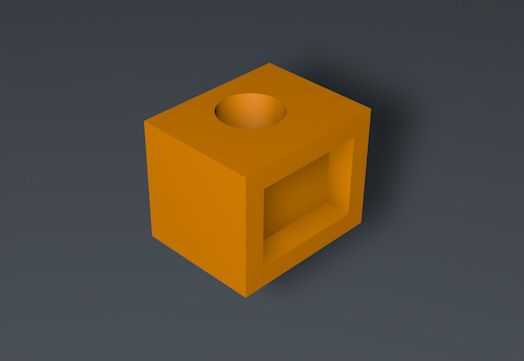

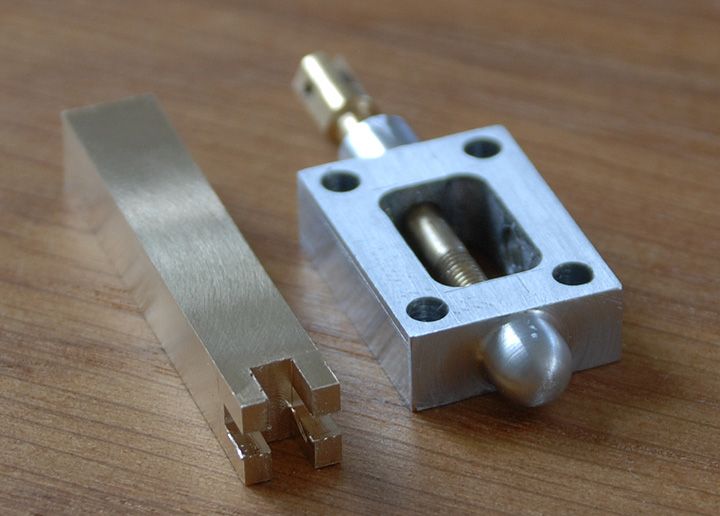

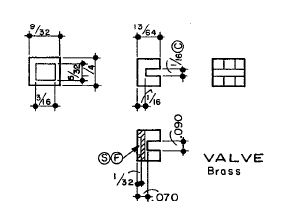

I'm building Elmers Grasshopper engine and the next part I'll do is the valve. But I can't figure out how the valve is designed. Can some smart guy at HMEM please tell me how I should do. I have seen some photos of such a valve but there is always two parts. In the plan I got there is only one part.

I'm building Elmers Grasshopper engine and the next part I'll do is the valve. But I can't figure out how the valve is designed. Can some smart guy at HMEM please tell me how I should do. I have seen some photos of such a valve but there is always two parts. In the plan I got there is only one part.