Hi, All,

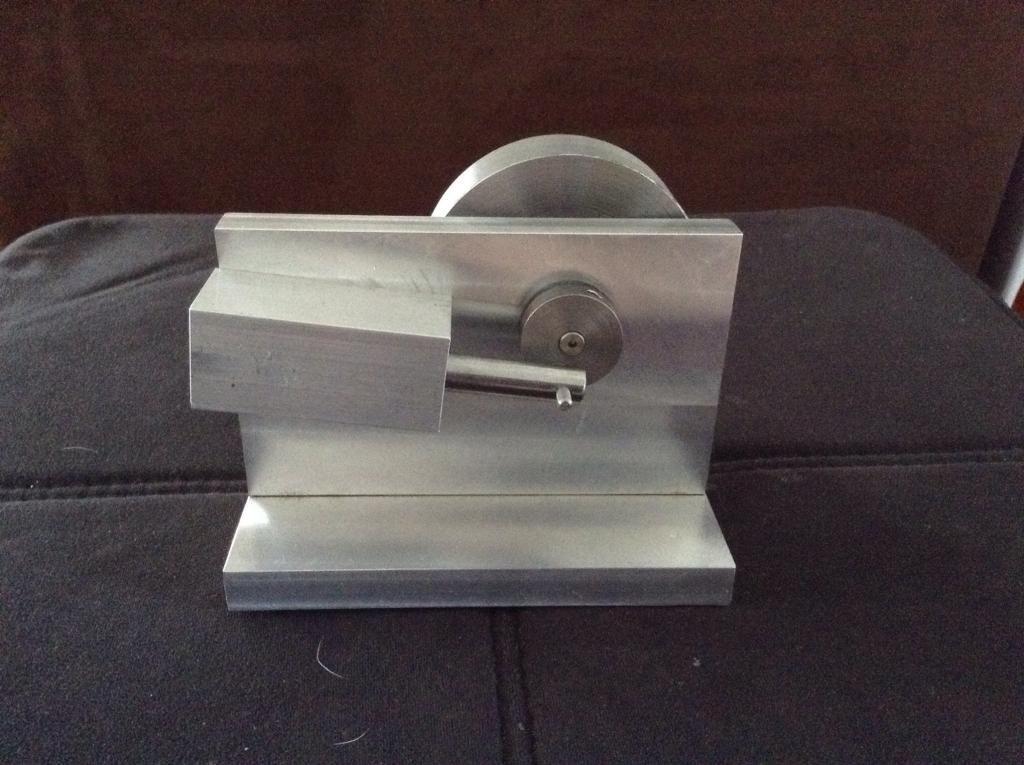

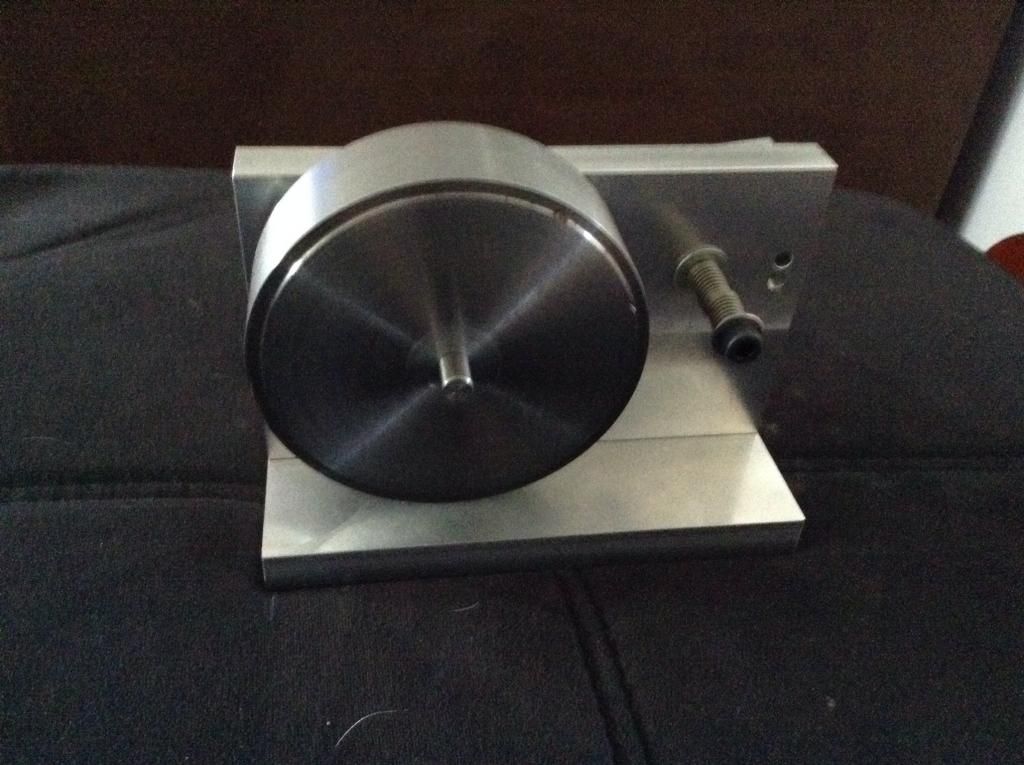

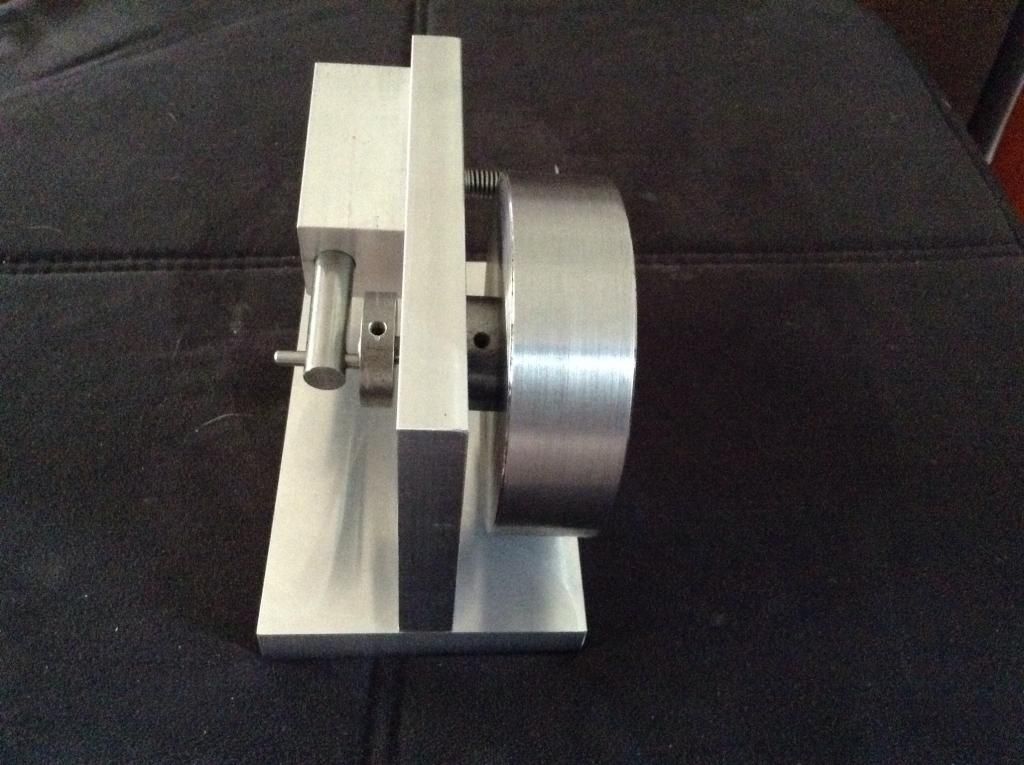

Well, I just finished machining and assembly of my Lucy-style wobbler this afternoon. I didn't chase down the air fitting yet, so I just held my air gun against the intake opening where the fitting would thread. I got half a turn, and then nothing. After numerous repeats, I realized that there was a little binding going on in a few spots, so I corrected them. (Opened the hole slightly in the piston and polished the crankshaft further to reduce it's diameter. In spite of being really careful to drill the crankdisk square, and making a little fixture to make sure it went in square when I pressed it in, it was still a bit off.) Now it makes about 1 3/4 turns but won't continue. I guess tomorrow I'll rig up the air properly so I can take some pictures/video while it's failing to run.

The one big variable is the spring. I tried to use a spring about the same wire diameter and spacing as the original plans, but whether I succeeded is anyone's guess. To compensate, I bought screws of various lengths so I can use them to adjust tension.

BTW, these original plans from Western Kentucky University have a few errors. There were numerous missing dimensions, most of which could be calculated from the other parts, but one of which could not. (This was the horizontal position of the crankshaft hole in the valve plate. I ended up scaling it from the drawings.) There were also some errors (wrong drill size specified for tapping a 10-32), and some things that I would have done differently (for example, using 10-32 threads for strength in aluminum. I would have specified a coarser thread, but this is a moot point since that was the wrong drill size issue [yes, I should have checked it myself BEFORE drilling] and I ended up going to 1/4-20.) I mention all this primarily in case someone else is using the plans. They were free, they were clear, and they got me started, so I'm glad they were available.

I'll post some photos/video tomorrow, and then maybe those of you with more experience than me (i.e., everyone on the site) can feel free to make suggestions...