D

DaveH

Guest

Hello all,

Im going to make a couple of Fly cutters to replace the ones that went missing.

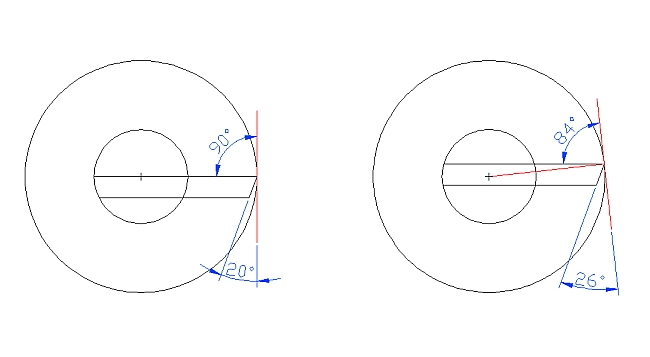

One thing I just cant get to grips with is why the slot for the cutter bit (HSS or whatever) is off set so that the cutters edge (the part that does the cutting) lines up with the centre line.

Seems most of the ones I have seen are like this.

Any comments?

Im going to make a couple of Fly cutters to replace the ones that went missing.

One thing I just cant get to grips with is why the slot for the cutter bit (HSS or whatever) is off set so that the cutters edge (the part that does the cutting) lines up with the centre line.

Seems most of the ones I have seen are like this.

Any comments?