Well, not technically my first, but the previous was many years ago on a different continent.

So I just received my machines (Sieg Super C3 & Super X1L) last week and figured I'd pick a little engine project to break them in and get some practice. I picked Elmer's #25 because it looked like a nice little design - and I just happened to have suitable stock lying around.

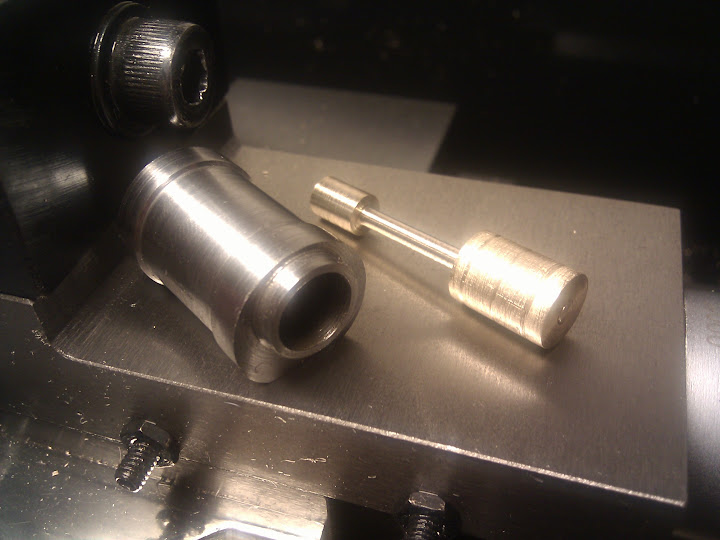

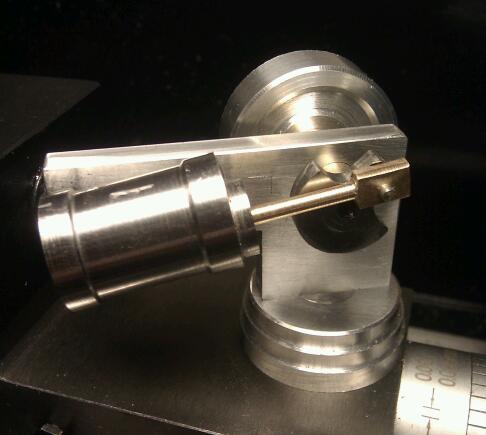

I got a start on it tonight by converting the plans to metric and making the piston (shown upside-down here):

The process used was to face and turn a length of brass bar down to the right diameter, then cut the oil grooves, centre drill, drill through with pilot bit for M3, then drill out the waste from the piston interior. I parted off to length and then tapped the M3 thread manually (I don't have a bottoming tap and I didn't want to run the risk of breaking my through tap). The brass was exceptionally easy to cut on the SC3 - 1mm passes didn't show any signs of struggle at all, and the parting cut was smooth sailling.

I don't have a reamer of the right diameter for the cylinder so I'm planning to use a boring bar to bring it to the right size. Should I plan to lap the cylinder and the piston together? Will I have any problems if I swap the cylinder to aluminium?

So I just received my machines (Sieg Super C3 & Super X1L) last week and figured I'd pick a little engine project to break them in and get some practice. I picked Elmer's #25 because it looked like a nice little design - and I just happened to have suitable stock lying around.

I got a start on it tonight by converting the plans to metric and making the piston (shown upside-down here):

The process used was to face and turn a length of brass bar down to the right diameter, then cut the oil grooves, centre drill, drill through with pilot bit for M3, then drill out the waste from the piston interior. I parted off to length and then tapped the M3 thread manually (I don't have a bottoming tap and I didn't want to run the risk of breaking my through tap). The brass was exceptionally easy to cut on the SC3 - 1mm passes didn't show any signs of struggle at all, and the parting cut was smooth sailling.

I don't have a reamer of the right diameter for the cylinder so I'm planning to use a boring bar to bring it to the right size. Should I plan to lap the cylinder and the piston together? Will I have any problems if I swap the cylinder to aluminium?