dwentz

Well-Known Member

- Joined

- Dec 20, 2007

- Messages

- 120

- Reaction score

- 5

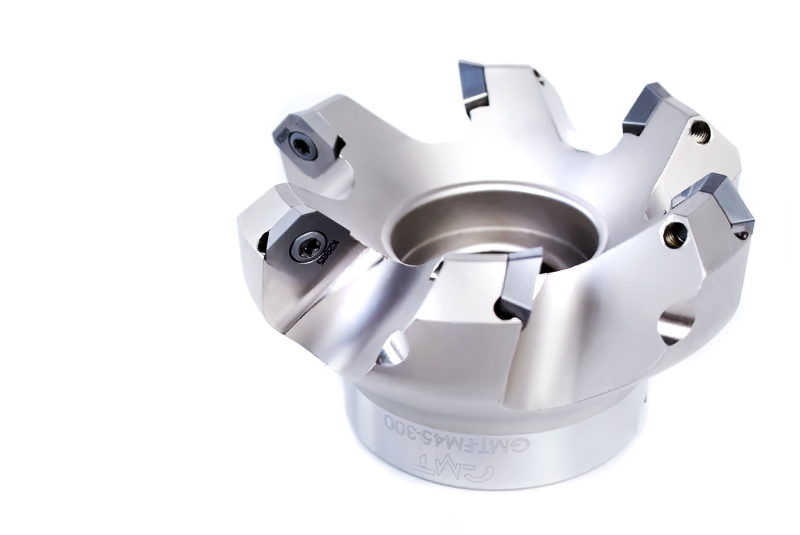

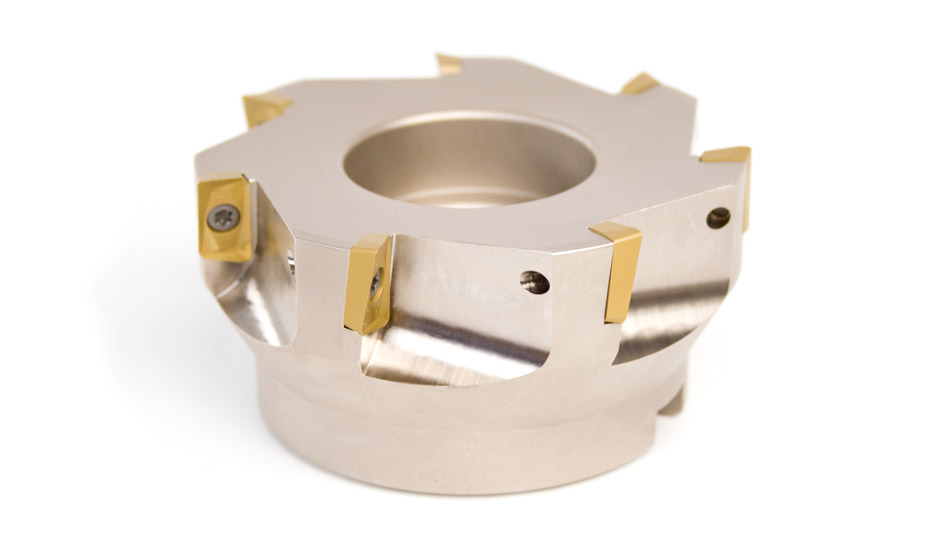

I am also looking for a good inexpensive face mill that has a MT2 mount.

I have a Mini Mill as well as a Clausing 8520 which has the MT2 so I have standardized on on the MT2 vs the MT3 of the Mini Mill.

I would like to hear from anyone that has used a small face mill on machines these sizes and their experience.

I have flycutters but am not supper happy with them. Most of the time I just use a 3/4 inch endmill and the finish is not great. It I need a super good finish the part goes in the shaper, but it would be nice to have something nice for in the mill when the part is already in the vise are held to the table.

Dale

I have a Mini Mill as well as a Clausing 8520 which has the MT2 so I have standardized on on the MT2 vs the MT3 of the Mini Mill.

I would like to hear from anyone that has used a small face mill on machines these sizes and their experience.

I have flycutters but am not supper happy with them. Most of the time I just use a 3/4 inch endmill and the finish is not great. It I need a super good finish the part goes in the shaper, but it would be nice to have something nice for in the mill when the part is already in the vise are held to the table.

Dale