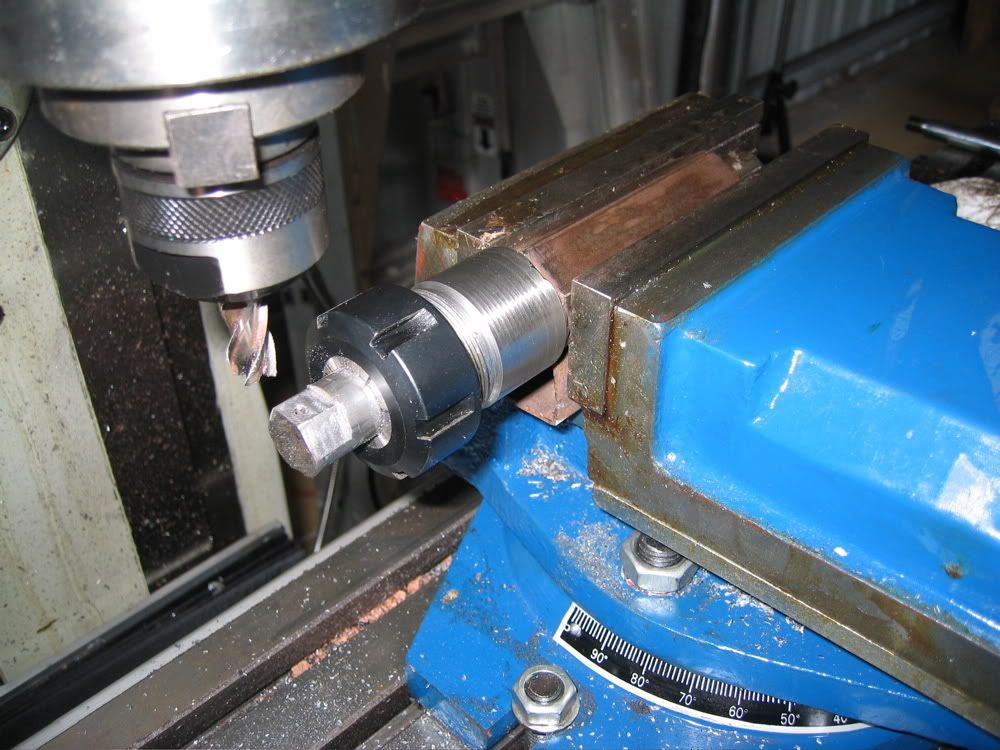

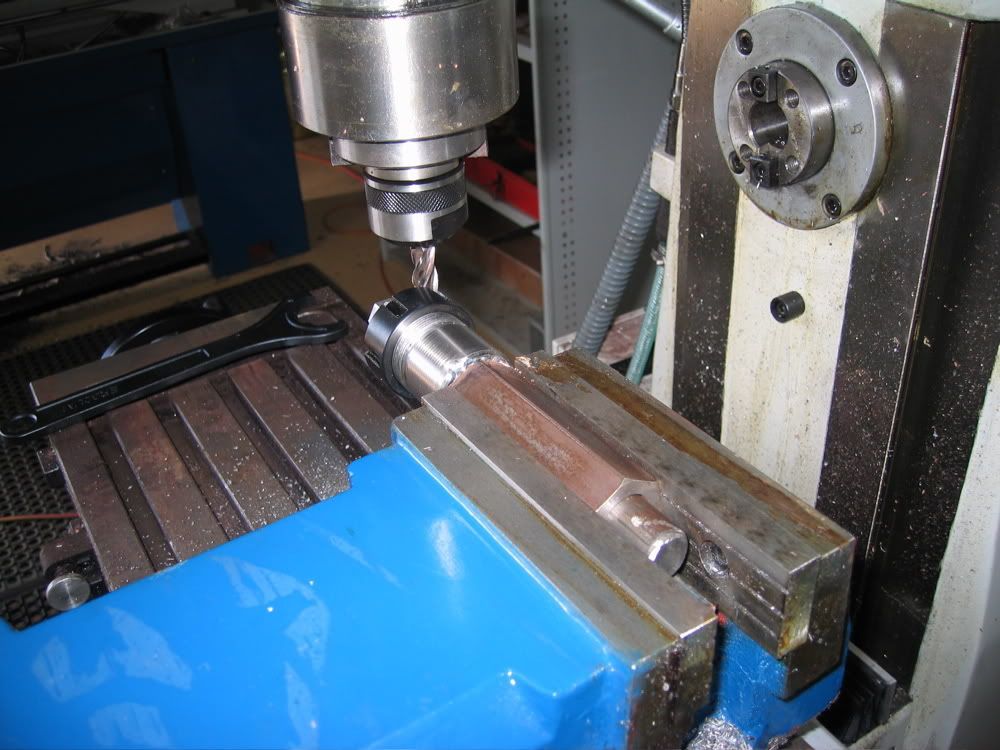

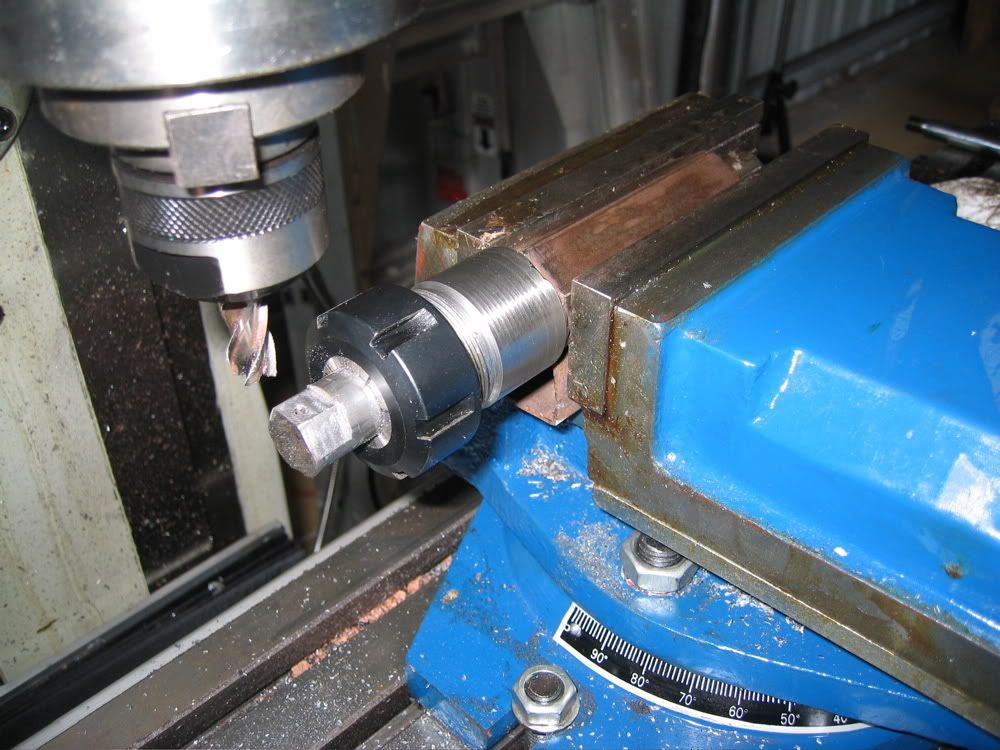

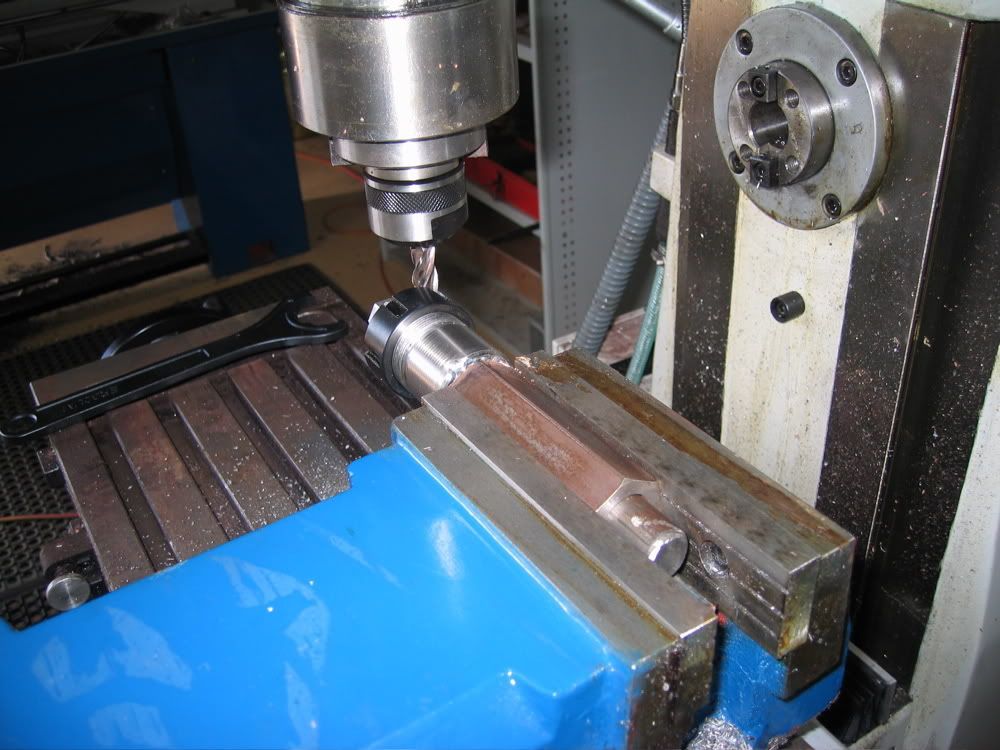

This is the ER version of the ubiquitous 5C hex collet block, and was inspired by Bogstandard's 5C to ER32 headstock adaptor, which enables the ER32 to be used as a pass through collet.

It was made using materials to hand, ie 32mm hex and 40mm round. A better solution (you always think of the better solution after making the job) would be to turn it from 1 piece of hex a little larger than the OD of the ER32 nut, ie 50mm+

Before making 'the proper one' I experimented on a piece of round to see if I could make an accurate well finished 8 deg internal taper combined with an external 40 x 1.5 single point thread, and so help me I did! So now I also have a round ER32 collet block which I can use when I need to.. need to.. er...

It was made using materials to hand, ie 32mm hex and 40mm round. A better solution (you always think of the better solution after making the job) would be to turn it from 1 piece of hex a little larger than the OD of the ER32 nut, ie 50mm+

Before making 'the proper one' I experimented on a piece of round to see if I could make an accurate well finished 8 deg internal taper combined with an external 40 x 1.5 single point thread, and so help me I did! So now I also have a round ER32 collet block which I can use when I need to.. need to.. er...