- Joined

- Apr 26, 2012

- Messages

- 93

- Reaction score

- 46

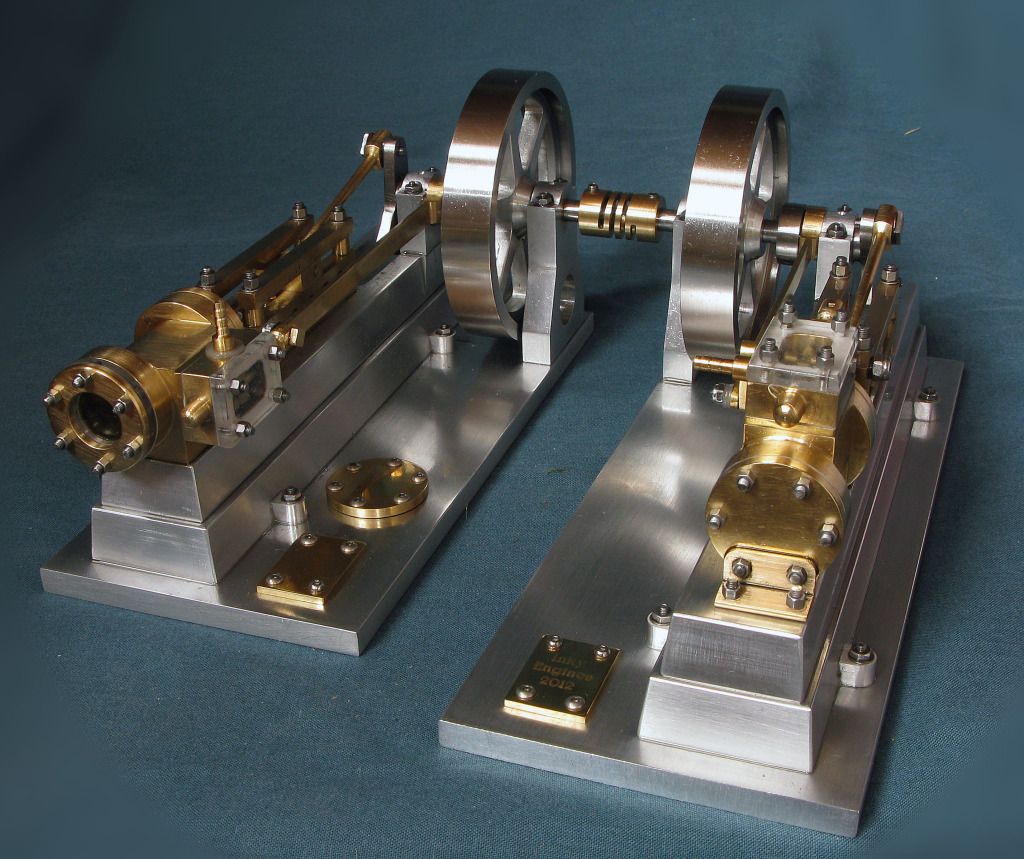

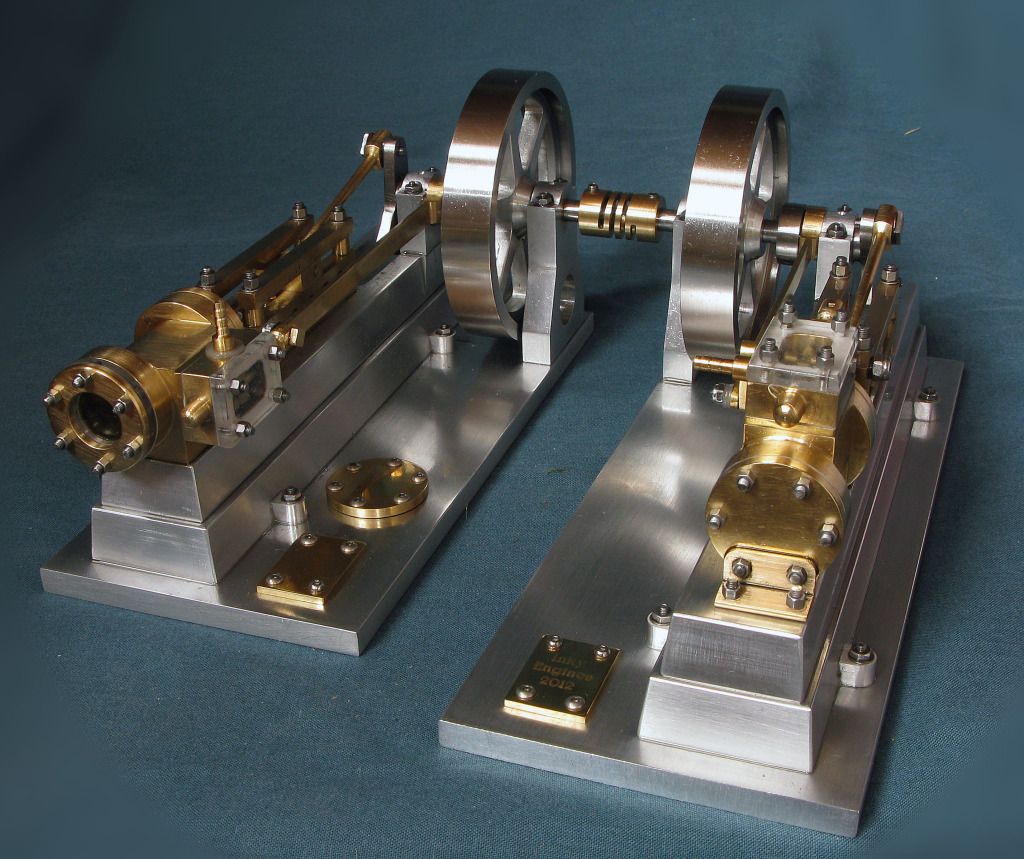

I've just finished the Inky Engines versions of Elmer's Mill #33 and Factory #41 Engines, and uploaded a You Tube video.

I'm not the first to decide to build these engines together given the many identical or similar parts, but I couldn't resist then connecting them together and running as a self starting unit.

I continue to be amazed at how well these small Elmer slide valve engines can run - before stripping down to take photographs I had the pair running together on compressed air at 1 psi, and could manage a few revs on breath power - on rebuilding 2 psi was required, but I expect this to fall as the setup beds in again.

These are the 8th and 9th of Elmer's designs built by Inky Engines, with the 10th a Comber Rotary Engine now running (but needing lots of air) and awaiting the video. I'm then hoping to make a start on Elmer's #5 Geared Engine in the next few weeks.

[ame]http://youtu.be/VpfbiwVe4hE[/ame]

Kind regards

Geoff at Inky Engines

I'm not the first to decide to build these engines together given the many identical or similar parts, but I couldn't resist then connecting them together and running as a self starting unit.

I continue to be amazed at how well these small Elmer slide valve engines can run - before stripping down to take photographs I had the pair running together on compressed air at 1 psi, and could manage a few revs on breath power - on rebuilding 2 psi was required, but I expect this to fall as the setup beds in again.

These are the 8th and 9th of Elmer's designs built by Inky Engines, with the 10th a Comber Rotary Engine now running (but needing lots of air) and awaiting the video. I'm then hoping to make a start on Elmer's #5 Geared Engine in the next few weeks.

[ame]http://youtu.be/VpfbiwVe4hE[/ame]

Kind regards

Geoff at Inky Engines