- Joined

- Apr 26, 2012

- Messages

- 93

- Reaction score

- 46

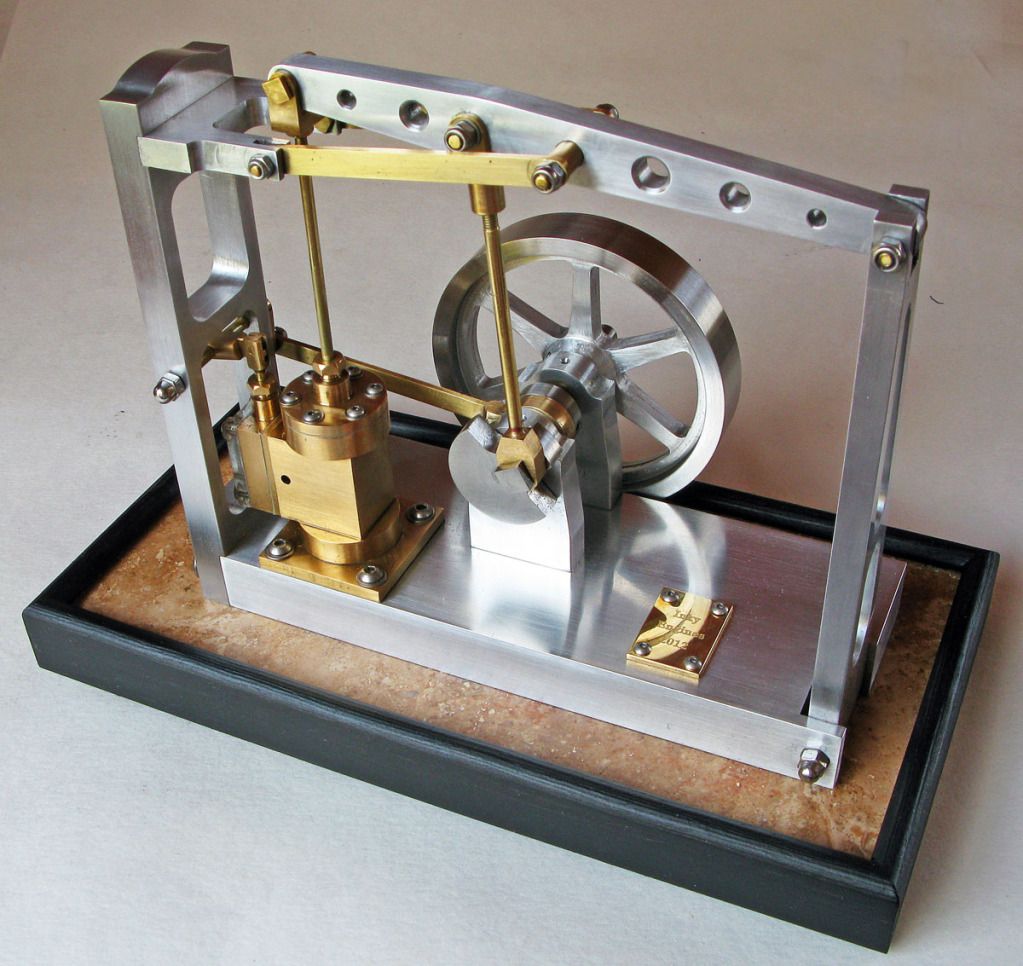

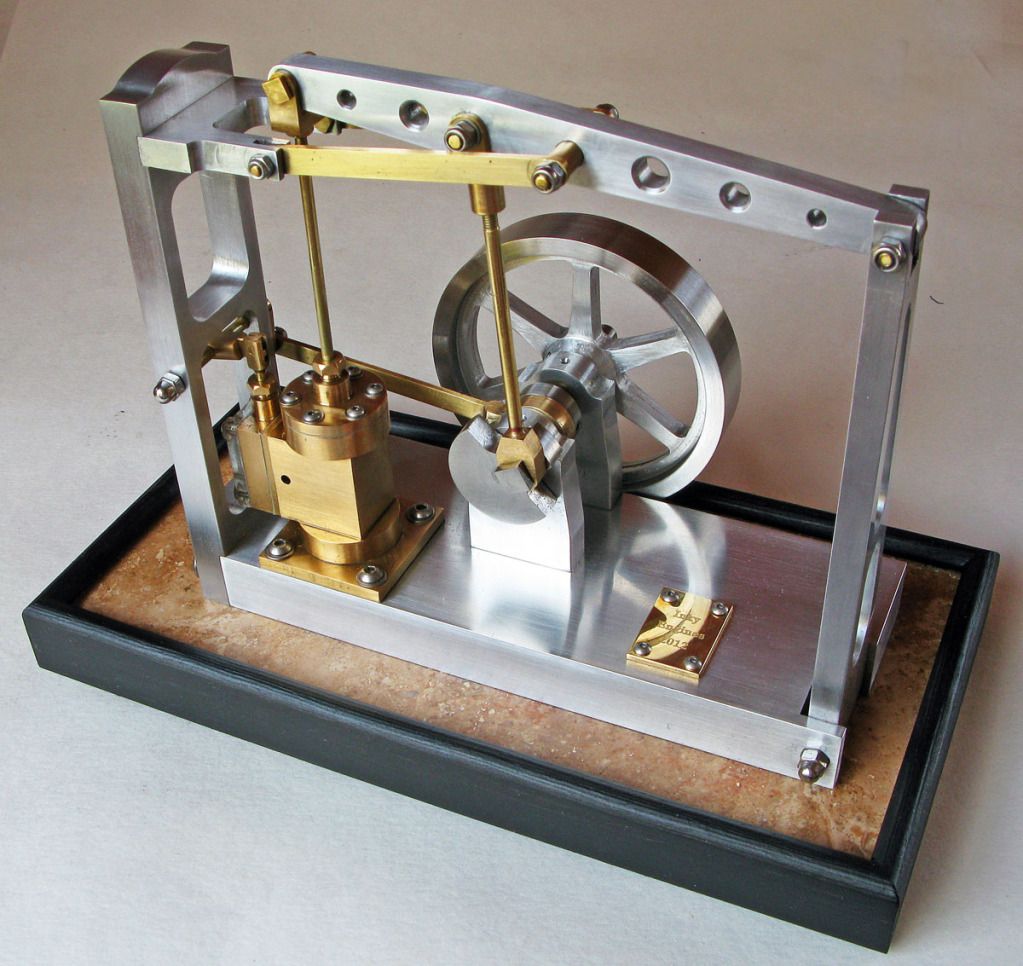

As promised, I've put together a video of the latest Elmer Verburg engine from the Inky Engines stable. It joins the wobblers and beam engine, videos of which were attached to my recent Newbie posting.

Please excuse my attempt to show pressure on the gauges ..... an expensive computer, excellent eyesight and quick reactions on the pause are probably necessary to read the dials on the video .... for anybody interested at slow tickover the engine is running on 1.5 psi at 166 rpm whilst on 7.5 psi it runs at 722 rpm ... full scale deflection on the left hand gauge is 15 psi and that on the right 60 psi ... I bought the 15 psi gauge upon realising that with the Elmer's engines I was building the needle barely moved on the 60 psi gauge. The grasshopper will of course run faster, but this is not imho appropriate for a beam engine!

[ame]http://www.youtube.com/watch?v=htVeQUjhWqU[/ame]

Now the grasshopper is consigned to the mantlepiece I will concentrate on completing Elmer's #33 Mill and #41 Factory Engines. I'm building these as a pair and may let them run together as a quasi twin cylinder slide valve set up ... not exactly realistic, but fun!

Kind regards

Geoff at Inky Engines

Please excuse my attempt to show pressure on the gauges ..... an expensive computer, excellent eyesight and quick reactions on the pause are probably necessary to read the dials on the video .... for anybody interested at slow tickover the engine is running on 1.5 psi at 166 rpm whilst on 7.5 psi it runs at 722 rpm ... full scale deflection on the left hand gauge is 15 psi and that on the right 60 psi ... I bought the 15 psi gauge upon realising that with the Elmer's engines I was building the needle barely moved on the 60 psi gauge. The grasshopper will of course run faster, but this is not imho appropriate for a beam engine!

[ame]http://www.youtube.com/watch?v=htVeQUjhWqU[/ame]

Now the grasshopper is consigned to the mantlepiece I will concentrate on completing Elmer's #33 Mill and #41 Factory Engines. I'm building these as a pair and may let them run together as a quasi twin cylinder slide valve set up ... not exactly realistic, but fun!

Kind regards

Geoff at Inky Engines