I've been fooling around with electronic ignitions for a while. Being basically a cheap kind of guy I thought maybe I could build one cheaper than buy one. Not only that but I like fooling around with electronic stuff, especially the kind that can shock me. well I made one. After it worked my buddy needed one too so I made another. Some of you might also need one so here I published the plans; schematic.

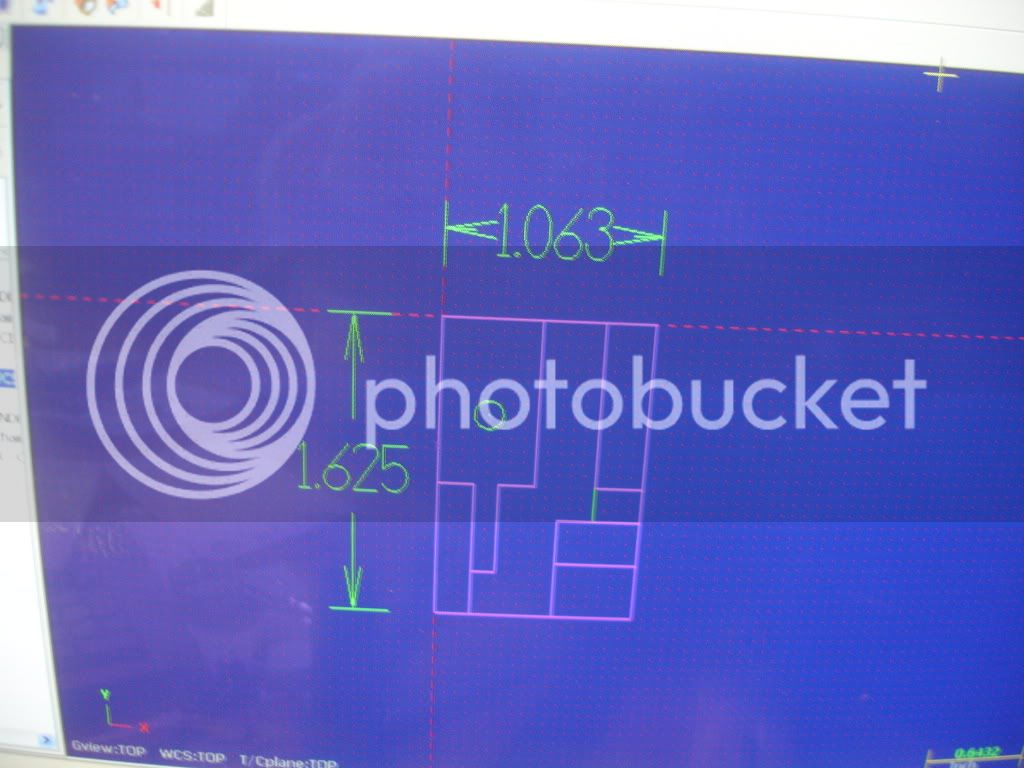

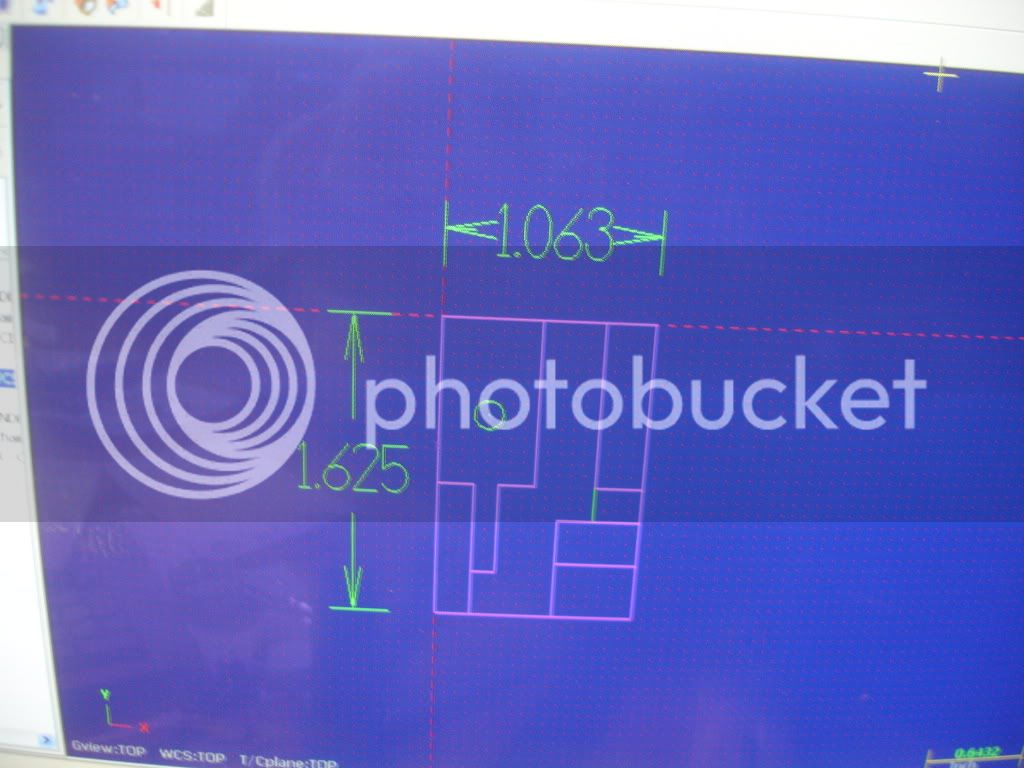

The next picture shows the cutting pattern for the circuit board. I milled each line 1/16 wide. The first one I built I ground the traces with a Dremel grinder. Milling made for a much nicer job. Why is one line green, I don't know.

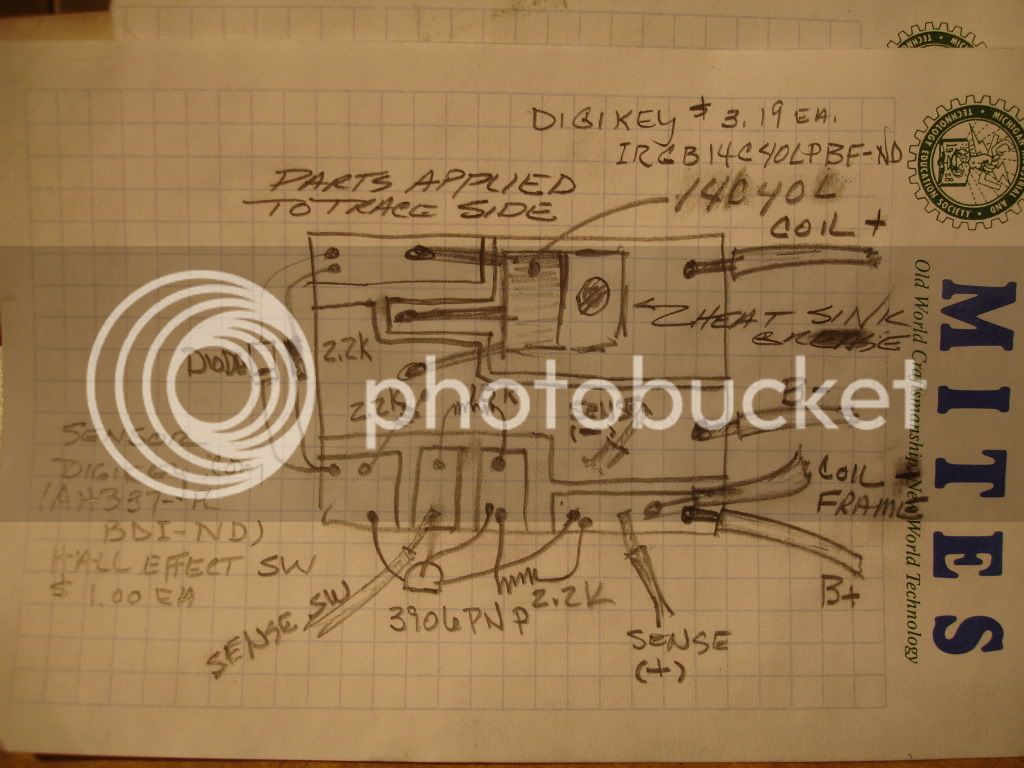

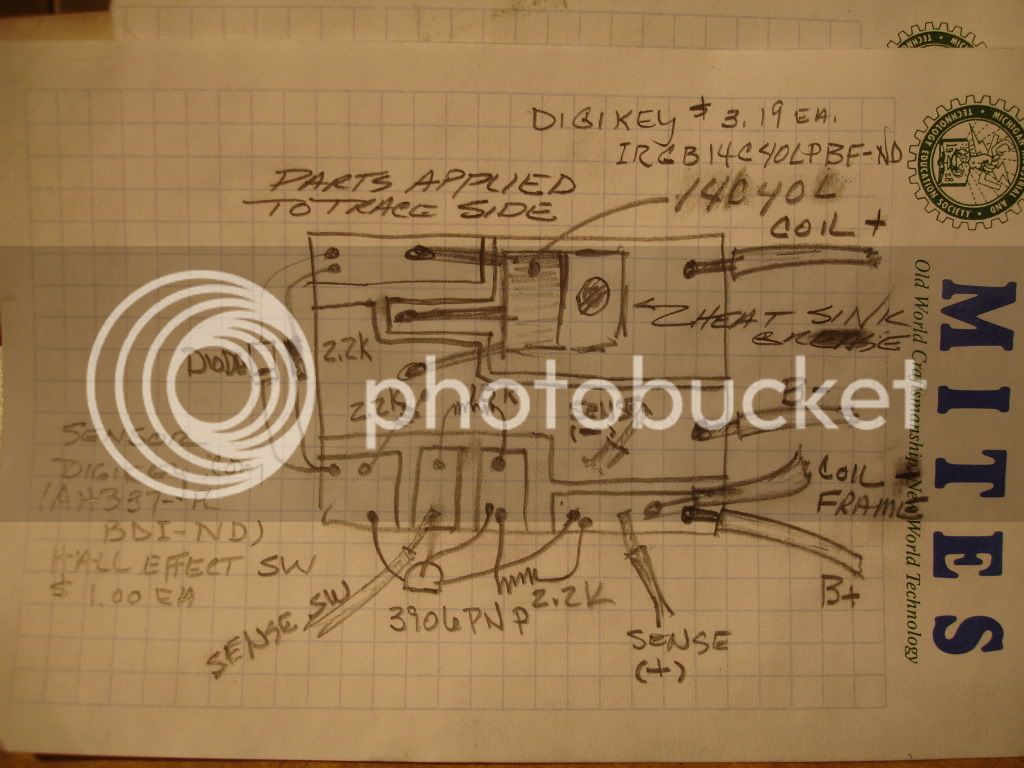

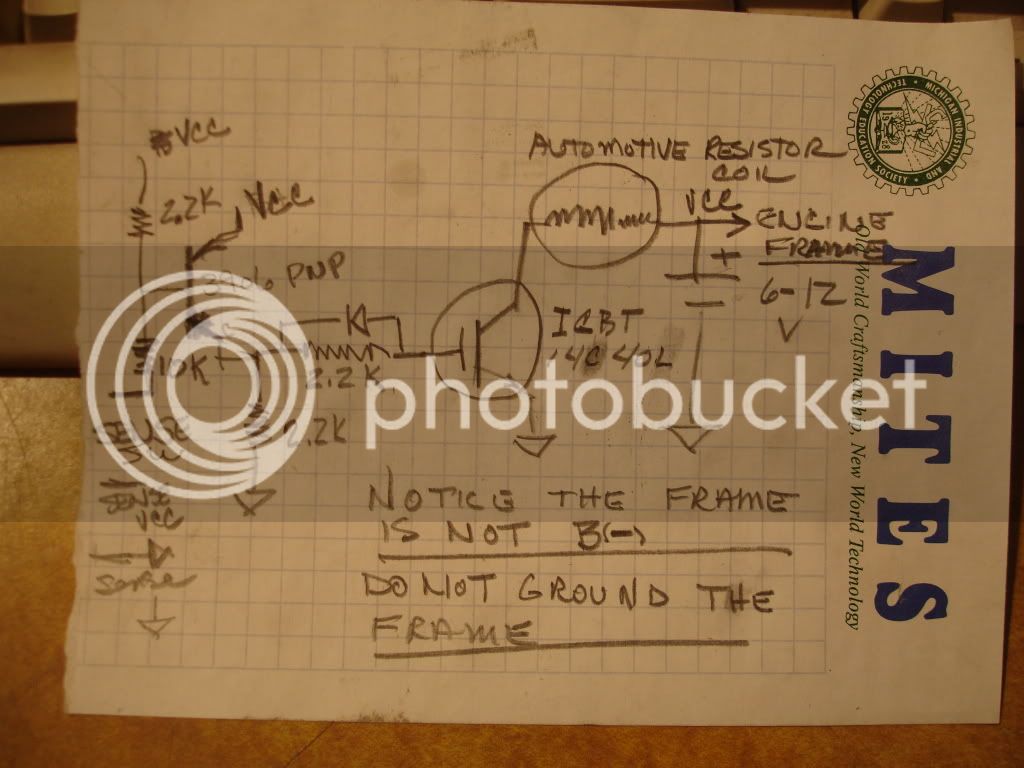

The next picture shows the parts layout. I included some infor about where to get the parts and current prices. Be sure to get a few hall effect sensors cuz they've been know to get zapped by the high tension. Keep all high tension wires and stuff away from the battery and the rest of the electronics or you'll zap a sensor. You'll need a south pole magnet attached to your camshaft or crank shaft to fire the sensor. Interesting too is that you can series multiple sensor outputs so, for example, on a hit'n miss you could arrange a sensor to block firing the plug when coasting; extend battery life. (I actually have never done that. I know you can parallel them. Maybe I ought to think about that a little more.)

The next picture shows the cutting pattern for the circuit board. I milled each line 1/16 wide. The first one I built I ground the traces with a Dremel grinder. Milling made for a much nicer job. Why is one line green, I don't know.

The next picture shows the parts layout. I included some infor about where to get the parts and current prices. Be sure to get a few hall effect sensors cuz they've been know to get zapped by the high tension. Keep all high tension wires and stuff away from the battery and the rest of the electronics or you'll zap a sensor. You'll need a south pole magnet attached to your camshaft or crank shaft to fire the sensor. Interesting too is that you can series multiple sensor outputs so, for example, on a hit'n miss you could arrange a sensor to block firing the plug when coasting; extend battery life. (I actually have never done that. I know you can parallel them. Maybe I ought to think about that a little more.)