Majorstrain

Well-Known Member

- Joined

- Dec 24, 2008

- Messages

- 304

- Reaction score

- 4

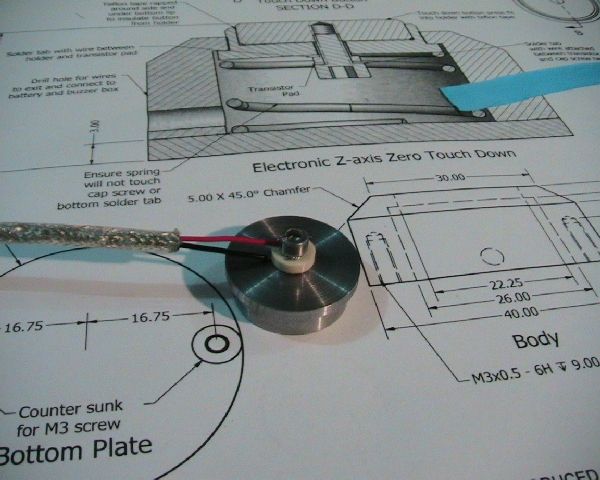

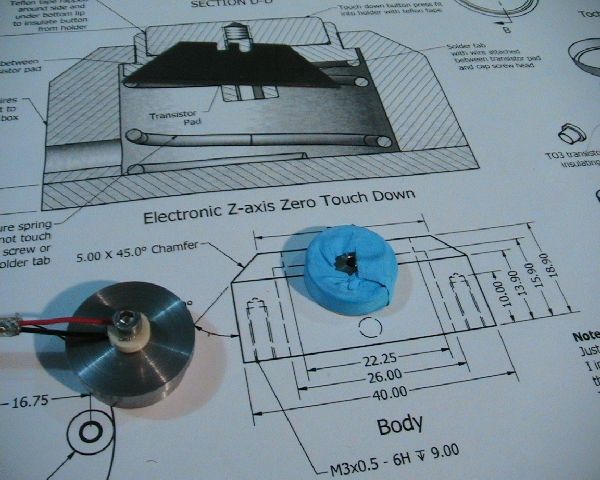

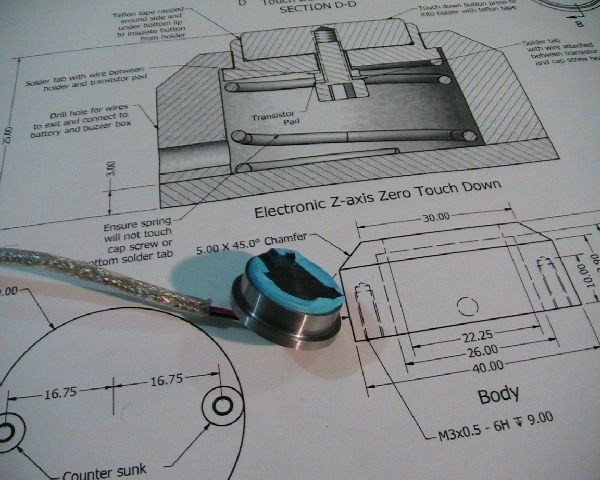

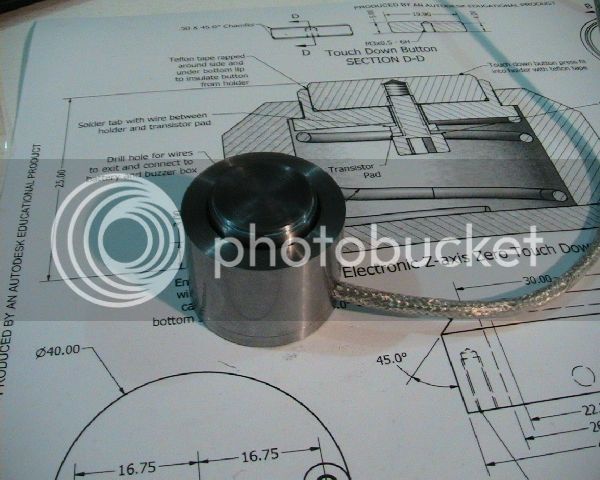

This is a small off shoot from making the QCTP. You how it goes, make a tool to make a tool to make a project. I'm waiting for the dovetail cutter anyway.

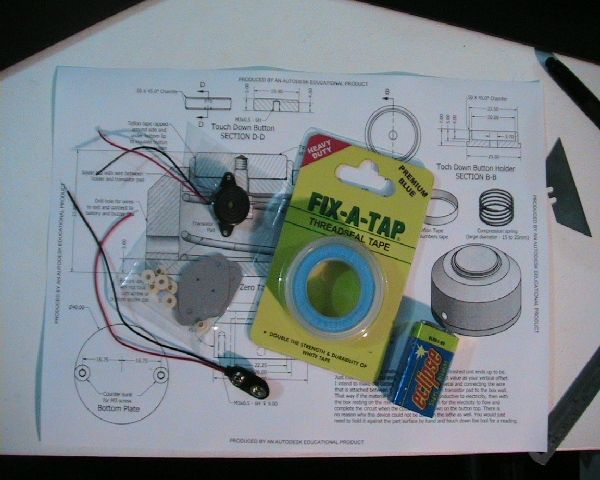

The electronic parts and cost under $10 and the spring I got from an auto shop for $2.50. All the steel is of unknown grade out of the scrap box, you could use ali for all but the top button.

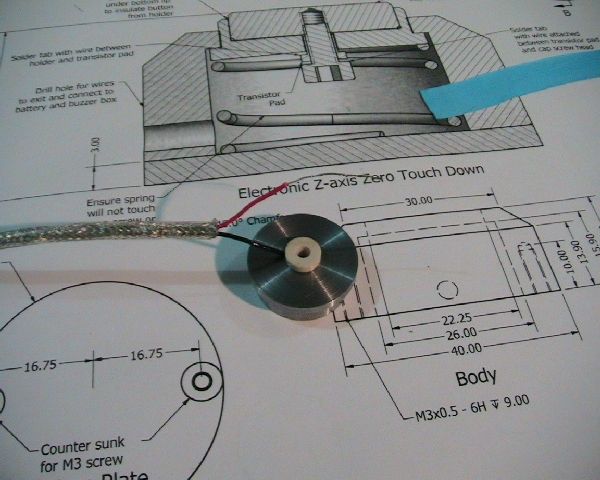

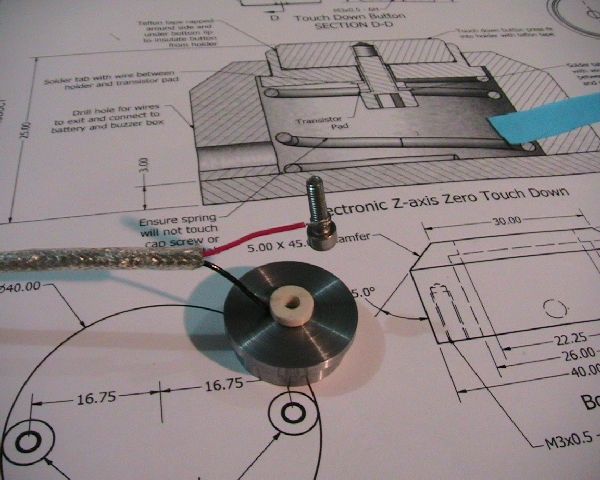

I changed the body size 35mm on mine because that was all I had. The consequence of the reduction was to use M2 screws to hold the base on instead of M3

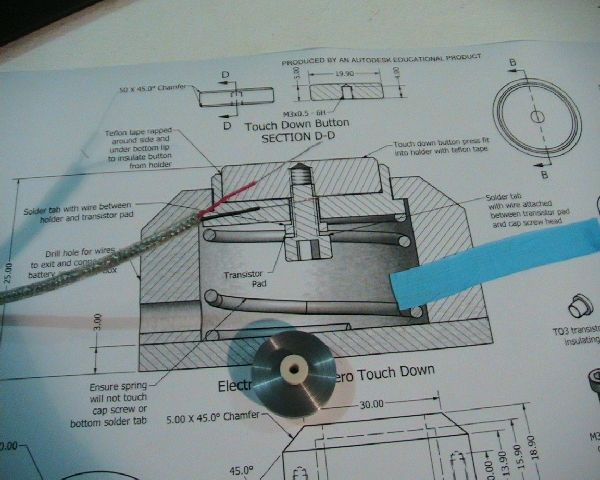

The Teflon plumbers tape is thicker than the standard but you can use whatever you like. The drawing also mentions a solder tab but I didn't need them in the end, I just wrapped the wire round the screw.

The final height does not have to be accurate, all you do is measure it and use that figure as you z-axis offset. Mine turned out at 25.08mm

Here is the drawing for the project

Enjoy

Phil

stand by for pics.

View attachment Z-axis zero.pdf

The electronic parts and cost under $10 and the spring I got from an auto shop for $2.50. All the steel is of unknown grade out of the scrap box, you could use ali for all but the top button.

I changed the body size 35mm on mine because that was all I had. The consequence of the reduction was to use M2 screws to hold the base on instead of M3

The Teflon plumbers tape is thicker than the standard but you can use whatever you like. The drawing also mentions a solder tab but I didn't need them in the end, I just wrapped the wire round the screw.

The final height does not have to be accurate, all you do is measure it and use that figure as you z-axis offset. Mine turned out at 25.08mm

Here is the drawing for the project

Enjoy

Phil

stand by for pics.

View attachment Z-axis zero.pdf