Was wondering what most do for distributors for 2 and 4 cylinder engines (or more). Do any of you make them or can you buy them? Are there any builds on one available? I see the ignition systems and Hall Sensors but haven't seen much on distributors. Enough questions for now. Ironman ................????? I know... Should go in Questions and Answers. Can it be moved? thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Distributor for Model Engines

- Thread starter ironman

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

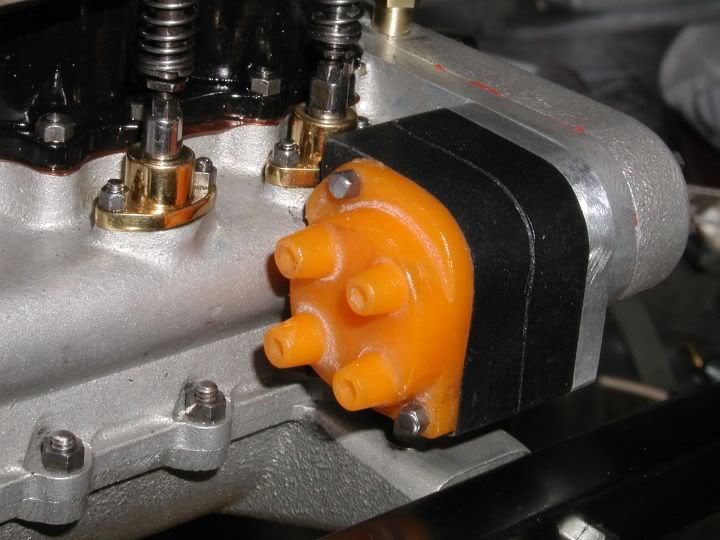

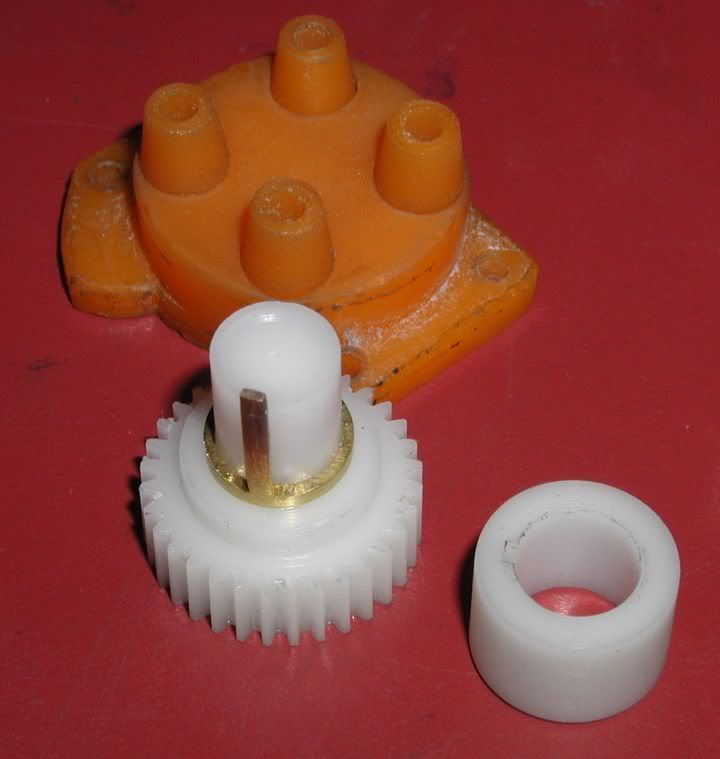

Here is the distributor for a V4 engine. The cap is clear acrylic with stainless screws in it. The rotor is the same with a piece of brass sheet super glued to it. The shaft has a steel disk on it that the magnets are pressed into for the hall sensor. The bevel gear is a match set with the gear on the cam. The brass spacer is used to set the mesh on the gears. The body is aluminum with 1/8 X 1/4 inch bearings pressed into each end to support the shaft.

S/S has started to carry the MJN molded caps but the rest will need to be fabricated. I picked up an 8 cylinder cap from him at the Zanesville show. Nice stuff!

The molded caps are not very deep. If you make your own cap you can keep more distance between the body of the distributor and the rotor. If you foul a plug you will need all the room you can get. Man there is fire shooting everywhere. It's Awesome!!

S/S has started to carry the MJN molded caps but the rest will need to be fabricated. I picked up an 8 cylinder cap from him at the Zanesville show. Nice stuff!

The molded caps are not very deep. If you make your own cap you can keep more distance between the body of the distributor and the rotor. If you foul a plug you will need all the room you can get. Man there is fire shooting everywhere. It's Awesome!!

Only have built one distributor. Made the distributor with idea wanting it to look like a magneto. Shown here before painting.

Instead of having the coil wire come in the center of the distributor cap had it come in behind the rotor front. Coil wire fits in groove of the rotor and contacts a brass ring which has a leg that goes forward to the distributor cap.

Been told and it makes sense that electricity doesn't like going around corners. So the rotor contact for the plugs goes out the side to meet the plug wire contacts.

Originally made the magneto/distributor body and the rotor out of some unknown plastic which I guessed was nylon. This did not work. Used the same rotor but made a new body out of micarta and this has been working good with the nylon rotor.

The distributor cap is also made out of some mystry plastic from my scrap plastic box. It is made out of 5 parts. As my poor memory recalls. The main part of the cap is one piece. Bored the area for the rotor, a flange area for the bolt area and and the OD in the plug area. Parted off. Fit cap on magneto body and drilled for the mounting bolts and the holes to be tapped for the mounting.

Turned stub on lathe that fit inside of distributor cap but had material to tap for mounting distributor. Remount in lathe and finish turning the outside of cap.

Drill 4 holes for the plug wire towers. Turn 4 towers to fit the holes and put a little taper on exposed part of towers to give that cast look. CA glued the towers in and used some CA glue and baking soda to make fillets around the towers. When all done painted with some plastic paint found at hobby store. You might want to test if using black plastic or black paint to see if it conducts high voltage electricity. Some might contain carbon for color and conduct electricity.

stevehuckss396 said:Here is the distributor for a V4 engine. The cap is clear acrylic with stainless screws in it. The rotor is the same with a piece of brass sheet super glued to it. The shaft has a steel disk on it that the magnets are pressed into for the hall sensor. The bevel gear is a match set with the gear on the cam. The brass spacer is used to set the mesh on the gears. The body is aluminum with 1/8 X 1/4 inch bearings pressed into each end to support the shaft.

S/S has started to carry the MJN molded caps but the rest will need to be fabricated. I picked up an 8 cylinder cap from him at the Zanesville show. Nice stuff!

The molded caps are not very deep. If you make your own cap you can keep more distance between the body of the distributor and the rotor. If you foul a plug you will need all the room you can get. Man there is fire shooting everywhere. It's Awesome!!

Steve, do you have any plans for this distributor? I am starting to design a v4 and this would be exactly what I am looking for...

Thanks!

Doug

Similar threads

- Replies

- 11

- Views

- 2K

- Replies

- 15

- Views

- 2K