I posted in another thread that I used my destop router a lot nowdays to do simple plate work, I think it was Rake who asked for more details.

Well here goes, I bought the router off the homeworkshop. org site, it was one of about 15 that a guy was selling. These had all been robbed in some way to keep a production line going.

Mine was the only gantry style router, all the rest had moving tables.

I wanted a gantry type as the footprint although being larger, is fixed. A moving bed tends to knock into things if you are not well organised [ like me ]

]

It was complete mechanical but missing the motors, mountings, couplings and all electronics. Motors nowadays are easily sourced and are cheap, mountings are always hidden inside a lump of aluminium and Oldham couplings are also cheap or even possible to make yourself and just buy the cheap torque disk.

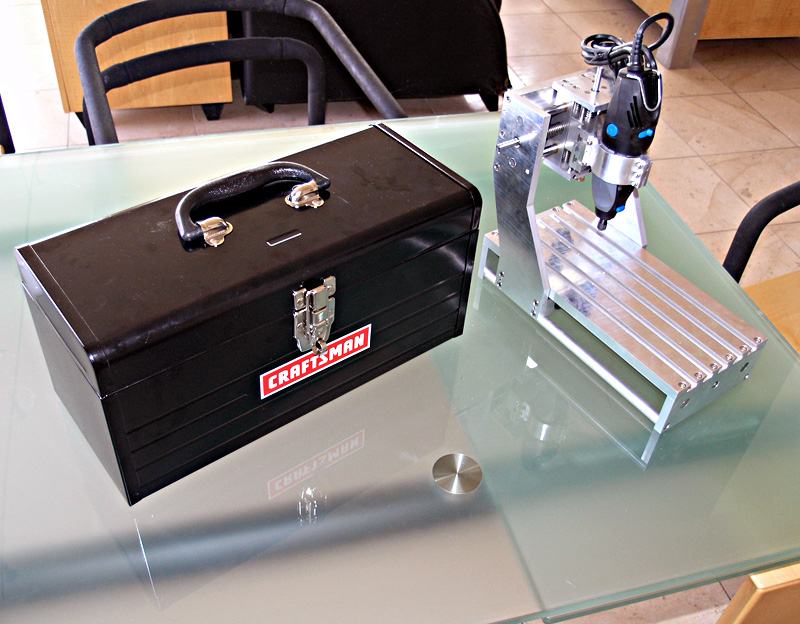

Shows the motors fitted but not fully assembled, i.e. lacking screw covers etc.

Time to see if it all works.

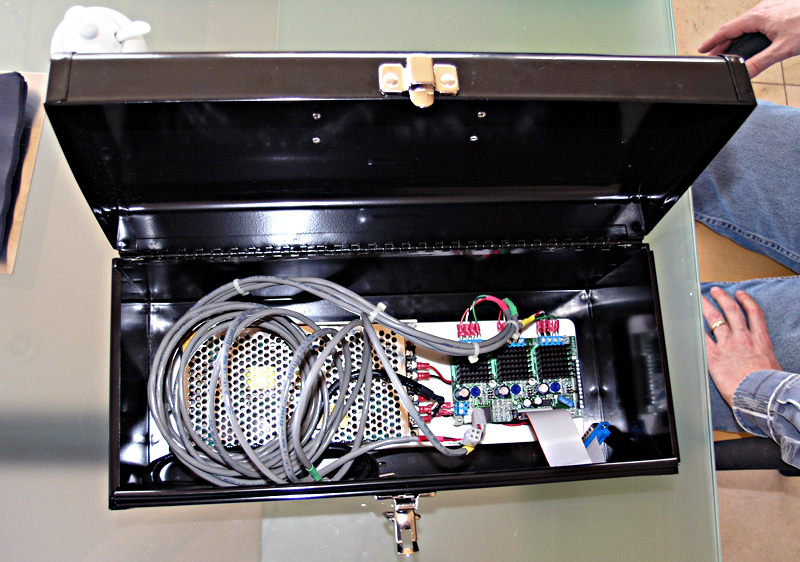

Shows it linked up to my test controller which is just an aluminium case with breakout board, power supply and 3 drives. This enables me to quickly plug into a machine to test motors etc. Everything worked and onto the next stage of finishing off and building a dedicated control box.

More to follow if there is enough interest.

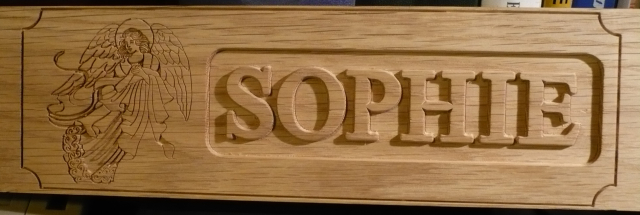

One teaser though is this badge, done as a spoof / test piece.

It's place in Wales with supposedly the longest name in the world, many people go to have their photo taken on the railway station platform. Note the tails of the six 'g's, all perfect and identical.

John _S.

Well here goes, I bought the router off the homeworkshop. org site, it was one of about 15 that a guy was selling. These had all been robbed in some way to keep a production line going.

Mine was the only gantry style router, all the rest had moving tables.

I wanted a gantry type as the footprint although being larger, is fixed. A moving bed tends to knock into things if you are not well organised [ like me

It was complete mechanical but missing the motors, mountings, couplings and all electronics. Motors nowadays are easily sourced and are cheap, mountings are always hidden inside a lump of aluminium and Oldham couplings are also cheap or even possible to make yourself and just buy the cheap torque disk.

Shows the motors fitted but not fully assembled, i.e. lacking screw covers etc.

Time to see if it all works.

Shows it linked up to my test controller which is just an aluminium case with breakout board, power supply and 3 drives. This enables me to quickly plug into a machine to test motors etc. Everything worked and onto the next stage of finishing off and building a dedicated control box.

More to follow if there is enough interest.

One teaser though is this badge, done as a spoof / test piece.

It's place in Wales with supposedly the longest name in the world, many people go to have their photo taken on the railway station platform. Note the tails of the six 'g's, all perfect and identical.

John _S.