Hi folks

i'm making a machine filer , not a model but will definatley help with making them

i was going to use a lineal bearing for the main bearing but i am now thinking about all this delrin i have here

the action of a filer is up and down often and fast, do you think delrin would handle this ok?

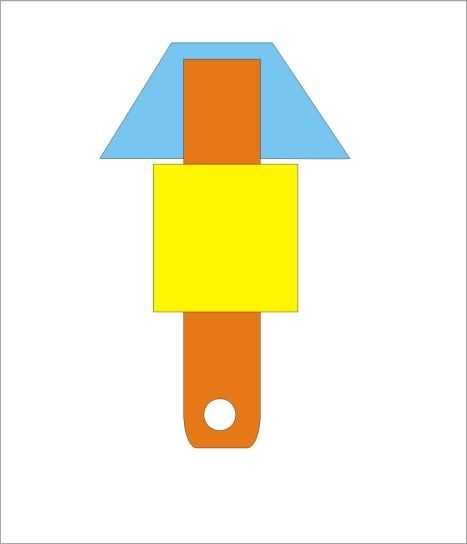

in the drawing below, the yellow is the delrin surround ( bearing) and the orange is also delrin ( shaft )

as is the blue swarf guard to prevent swarf or metal filings getting into the bearing section

think this would work?? the blue and orange sections would be going up and down between 1500 and 4000 times minute and have a travel length of about 10 mm ( 3/8")

i think it would be ok if i greased it ok but i aint a materials expert ( in fact i just dont know )

cheers

jack

i'm making a machine filer , not a model but will definatley help with making them

i was going to use a lineal bearing for the main bearing but i am now thinking about all this delrin i have here

the action of a filer is up and down often and fast, do you think delrin would handle this ok?

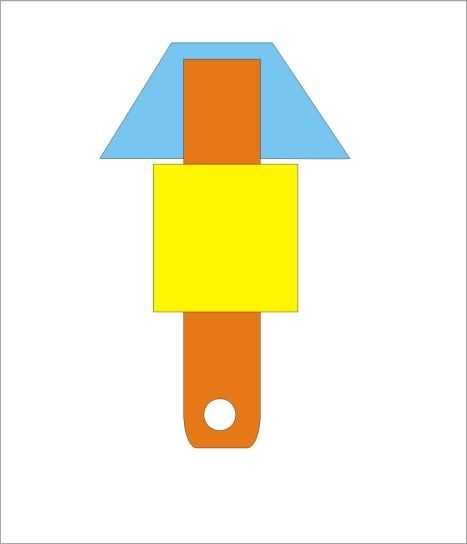

in the drawing below, the yellow is the delrin surround ( bearing) and the orange is also delrin ( shaft )

as is the blue swarf guard to prevent swarf or metal filings getting into the bearing section

think this would work?? the blue and orange sections would be going up and down between 1500 and 4000 times minute and have a travel length of about 10 mm ( 3/8")

i think it would be ok if i greased it ok but i aint a materials expert ( in fact i just dont know )

cheers

jack