BobWarfield

Well-Known Member

- Joined

- Dec 27, 2007

- Messages

- 1,151

- Reaction score

- 1

Most machining operations leave little burrs and sharp edges. You want to remove these, first so you don't cut yourself or others, and second because its just a bit of craftsmanship that ought to go into what you are doing. There are a lot of ways to deburr as well as tools to make it easier. Here is my array of deburring equipment:

Let's go left to right, top to bottom:

- Top left is my 1/4" mini-belt sander. That thing is very useful! The fancy nice versions are called "Dynafile" from "Dynabrade". Too much money. Mine is a cheap Asian knock off and it has worked flawlessly. What a nice little "power file".

- Next we have some files, railroad chalk, and heavy cutting oil. The two tiny little files are Grobet. They're European and can be bought from a seller in Europe on eBay. Shipping is cheap and the files are excellent quality. I found them one time by noticing an eBay buyer was one of the long time posters at one of the boards and checking into what he'd been buying to get some ideas. The larger files are Nicholson's. One is a normal mill file, while the other is a "Lathe" file. Lathe files are superb for use on the lathe. I use the chalk and heavy sulfurized cutting oil to keep the files from loading up. It helps. I should've pictured my file brush too, but didn't grab it.

- Back to the left we have a tapered reamer. This is the one I remembered dad using in my childhood. I got one, but almost never use it.

- The air drill with Keo Zero Flute is my favorite fast way to deburr a hole. Watch for the Keo's to be on sale at Enco and other places as they're not cheap otherwise. I've got a smaller Keo in the little hand crank drill too.

- Two scrapers. One is a conventional blade scraper with swiveling blade. It works fantastically well for a lot of things. Larger holes are easily deburred with a quick swipe as are long straight edges. Use only sharp blades or they start to catch and leave nicks. The other is actually a plastics and laminate cutter made by Olfa. I got the idea for the latter from Bogstandard on these boards.

- Far left are two pieces of 220 grit stone. They're a real handy size for the lathe and other work. I think mine are made by Gesswein, which is a good brand. I got a box of them on ebay for cheap that will last a lifetime. I need to chase down a little coarser grit versions some day soon.

- All the way on the right I'm demonstrating a Guy Lautard technique of using a file with a bit of sandpaper wrapped over it. This works well on the lathe too and will leave a finer finish than a straight file.

Always remember to be especially careful deburring things that are spinning, such as on the lathe. You don't want to get caught up in that or serious injury can result!

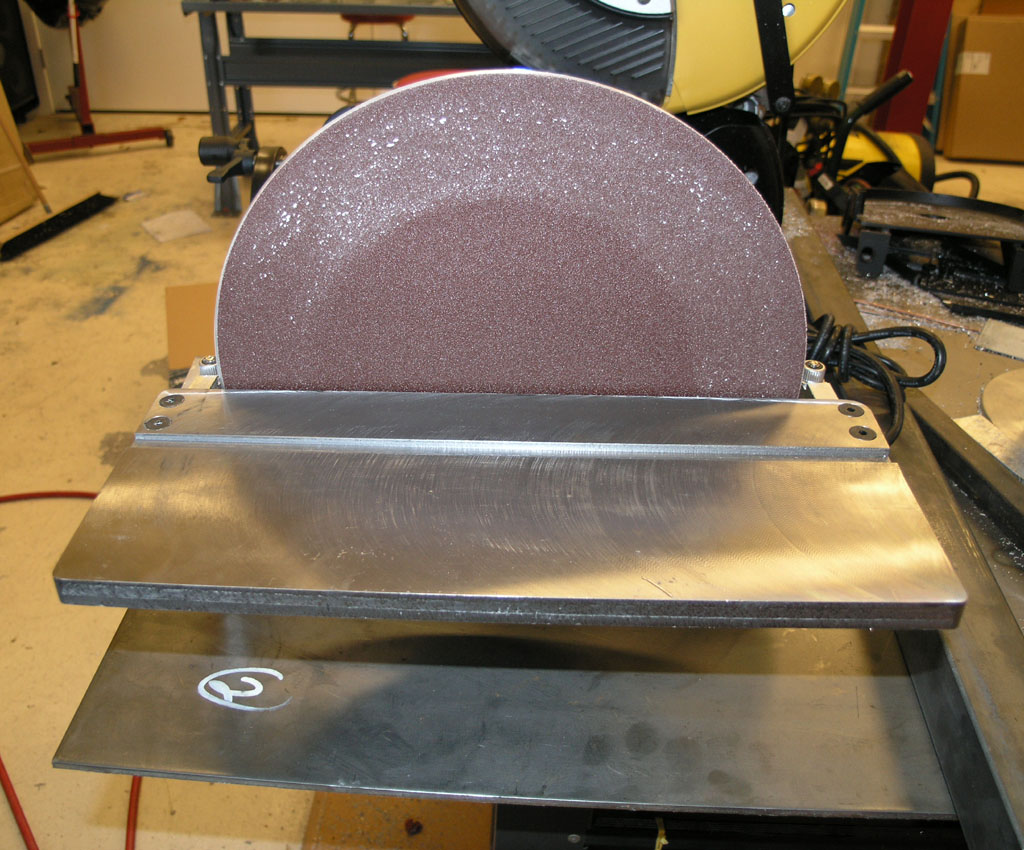

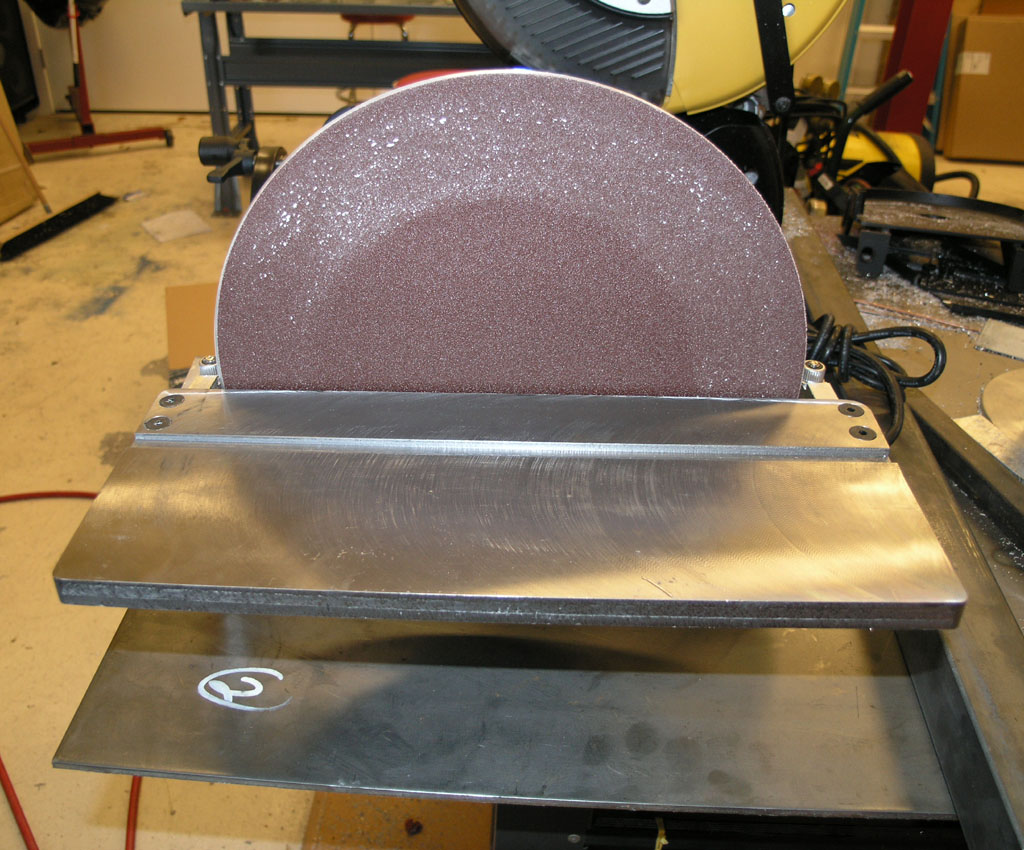

When all else fails, I have my super deburring tool that I just made, my 12" Disc Sander:

I know some of you made that slick deburring gadget Oldmech came up with. What other deburring tools and suggestions do you have?

Best,

BW

Let's go left to right, top to bottom:

- Top left is my 1/4" mini-belt sander. That thing is very useful! The fancy nice versions are called "Dynafile" from "Dynabrade". Too much money. Mine is a cheap Asian knock off and it has worked flawlessly. What a nice little "power file".

- Next we have some files, railroad chalk, and heavy cutting oil. The two tiny little files are Grobet. They're European and can be bought from a seller in Europe on eBay. Shipping is cheap and the files are excellent quality. I found them one time by noticing an eBay buyer was one of the long time posters at one of the boards and checking into what he'd been buying to get some ideas. The larger files are Nicholson's. One is a normal mill file, while the other is a "Lathe" file. Lathe files are superb for use on the lathe. I use the chalk and heavy sulfurized cutting oil to keep the files from loading up. It helps. I should've pictured my file brush too, but didn't grab it.

- Back to the left we have a tapered reamer. This is the one I remembered dad using in my childhood. I got one, but almost never use it.

- The air drill with Keo Zero Flute is my favorite fast way to deburr a hole. Watch for the Keo's to be on sale at Enco and other places as they're not cheap otherwise. I've got a smaller Keo in the little hand crank drill too.

- Two scrapers. One is a conventional blade scraper with swiveling blade. It works fantastically well for a lot of things. Larger holes are easily deburred with a quick swipe as are long straight edges. Use only sharp blades or they start to catch and leave nicks. The other is actually a plastics and laminate cutter made by Olfa. I got the idea for the latter from Bogstandard on these boards.

- Far left are two pieces of 220 grit stone. They're a real handy size for the lathe and other work. I think mine are made by Gesswein, which is a good brand. I got a box of them on ebay for cheap that will last a lifetime. I need to chase down a little coarser grit versions some day soon.

- All the way on the right I'm demonstrating a Guy Lautard technique of using a file with a bit of sandpaper wrapped over it. This works well on the lathe too and will leave a finer finish than a straight file.

Always remember to be especially careful deburring things that are spinning, such as on the lathe. You don't want to get caught up in that or serious injury can result!

When all else fails, I have my super deburring tool that I just made, my 12" Disc Sander:

I know some of you made that slick deburring gadget Oldmech came up with. What other deburring tools and suggestions do you have?

Best,

BW