Oldmechthings

Well-Known Member

- Joined

- Jan 10, 2008

- Messages

- 153

- Reaction score

- 12

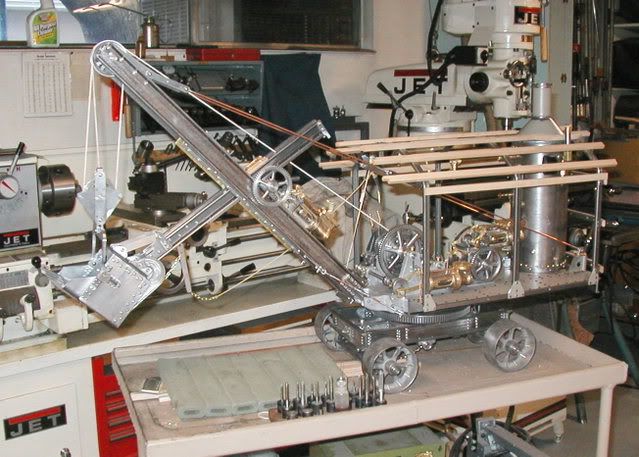

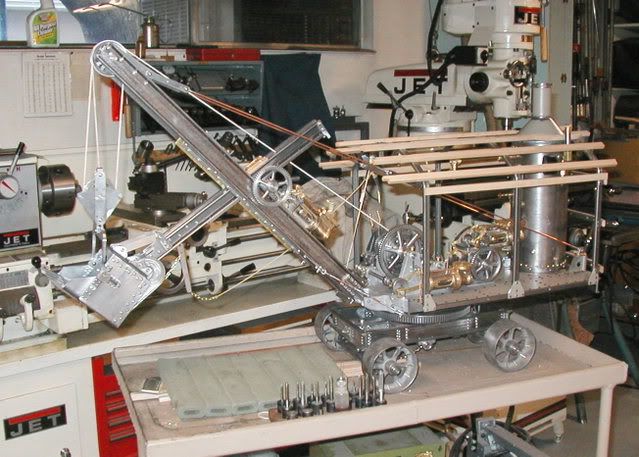

The steam shovel model has progressed to a point where it could have its corrugated roofing installed. But where do you find "scale" roofing?

Make it of course.

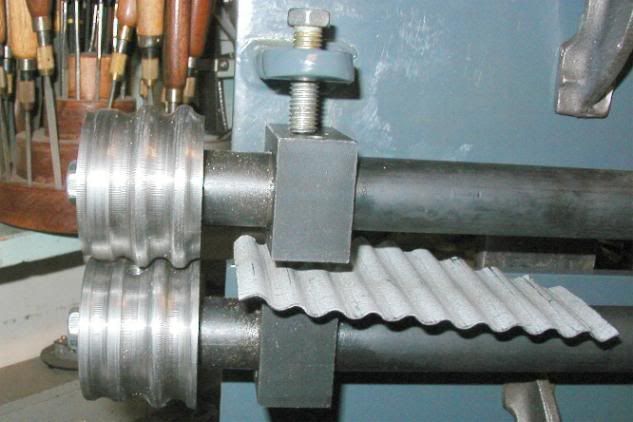

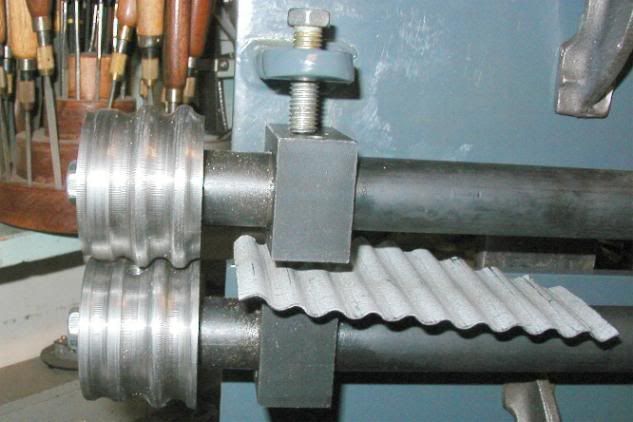

Forming roll dies were machined for a hand cranked Chinese built beading machine with an 18" throat. At first it would not work very well because it was not rigid enough and flexed. However machining some of the ridges off the rolls it works much better, as can be seen by the sample tested.

The metal being formed was salvaged from the side of a discarded clothes drier. That is a good source of material. I use it all the time. Now I can proceed and form the roof, and the machine has enough throat that I believe I can do it in one piece if I start at the center and work both ways.

After I showed the sample piece to a friend, he suggested that I could start manufacturing scrubbing boards. That is real good advice, except 100 years too late.

Birk

Make it of course.

Forming roll dies were machined for a hand cranked Chinese built beading machine with an 18" throat. At first it would not work very well because it was not rigid enough and flexed. However machining some of the ridges off the rolls it works much better, as can be seen by the sample tested.

The metal being formed was salvaged from the side of a discarded clothes drier. That is a good source of material. I use it all the time. Now I can proceed and form the roof, and the machine has enough throat that I believe I can do it in one piece if I start at the center and work both ways.

After I showed the sample piece to a friend, he suggested that I could start manufacturing scrubbing boards. That is real good advice, except 100 years too late.

Birk