Dan Rowe

Well-Known Member

- Joined

- Feb 12, 2010

- Messages

- 594

- Reaction score

- 18

Progress has been slow on this build but I have a couple of of cylinders done.

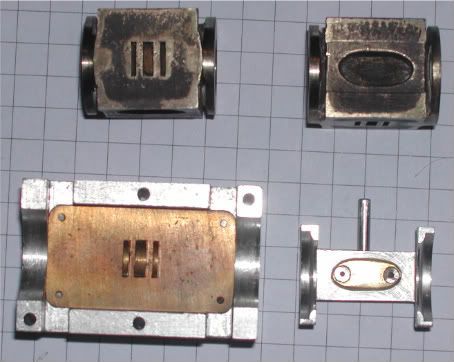

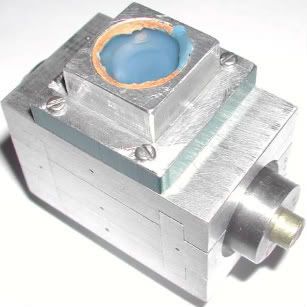

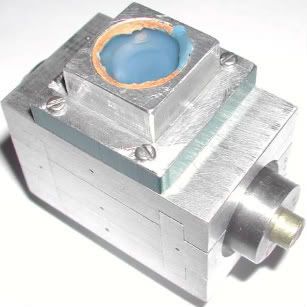

This is the metal wax injection mold with full steam passages. The injection point is rubber that I vulcanised in a bolt on part.

This is the other side.

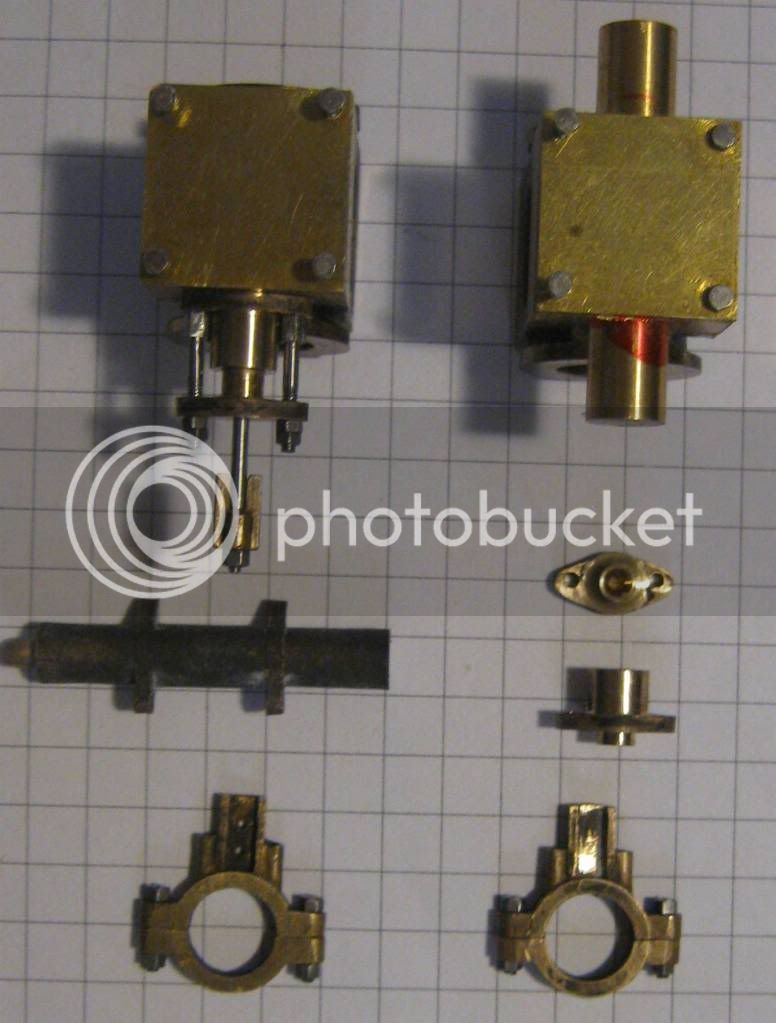

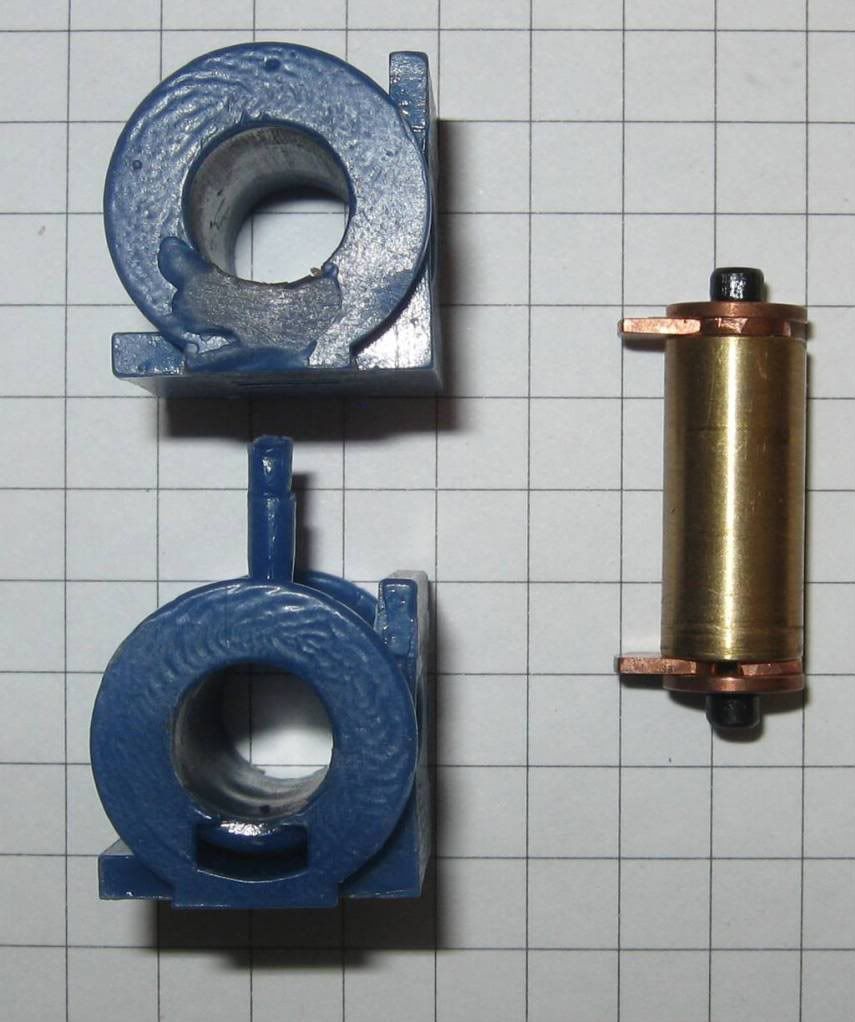

The exploded view.

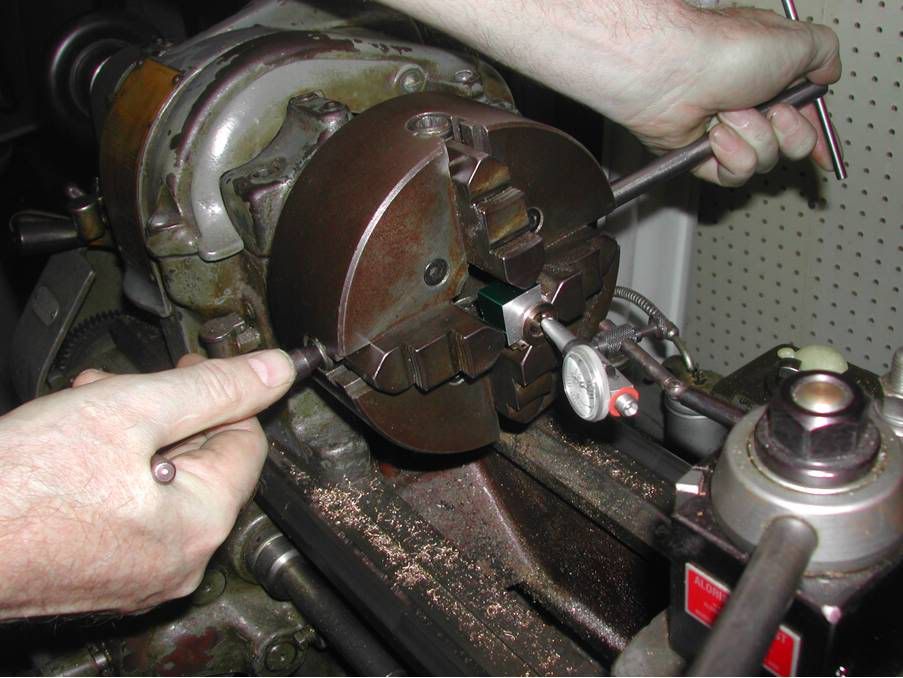

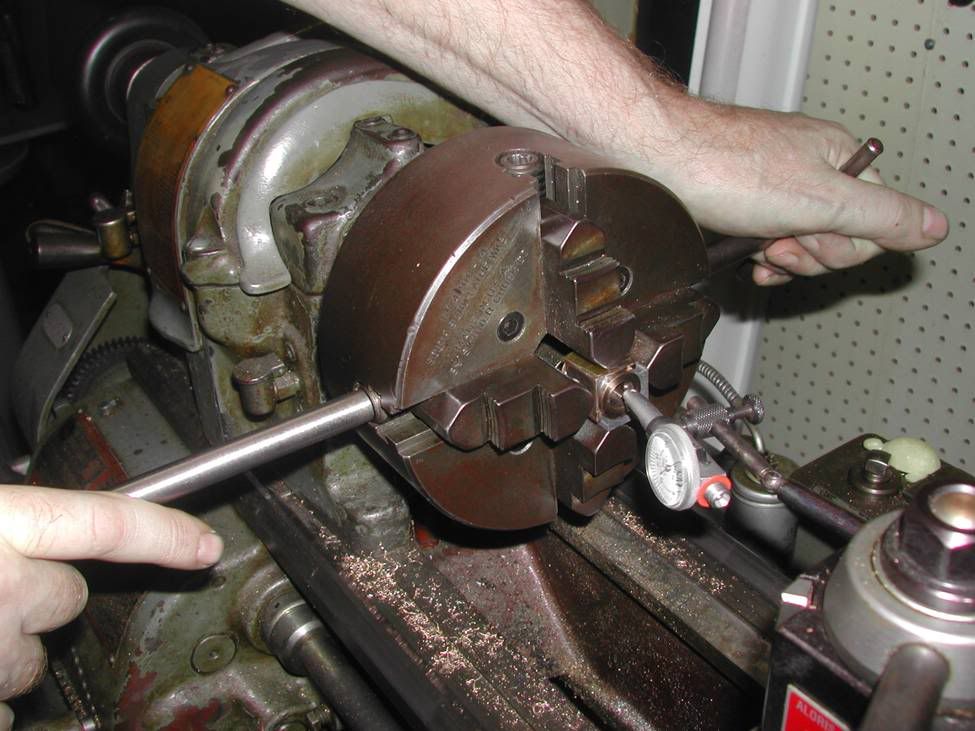

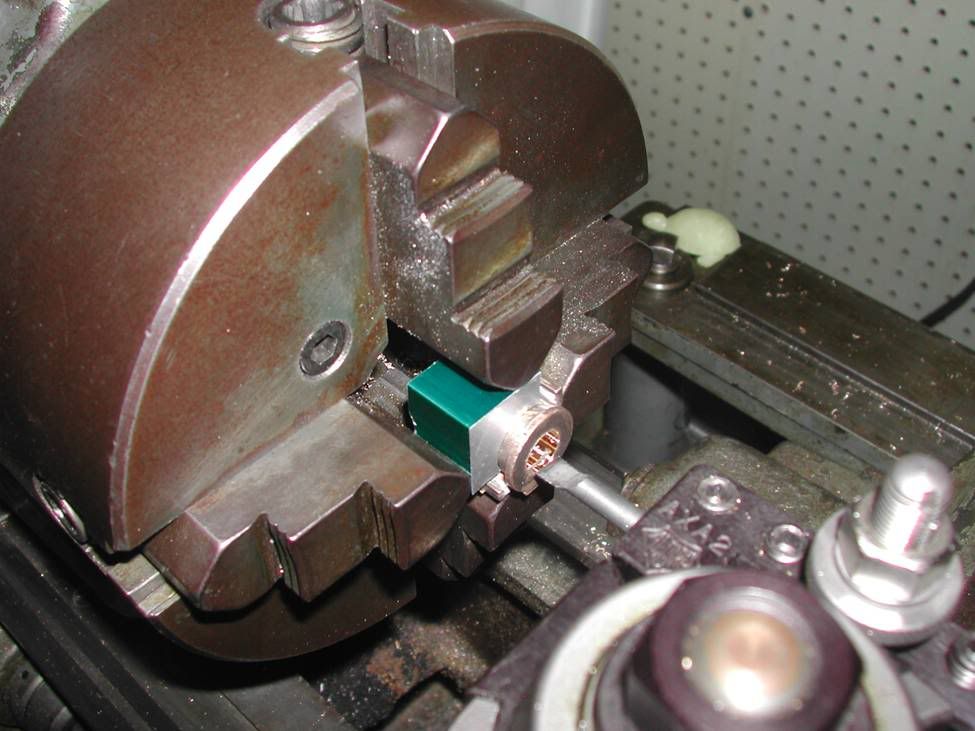

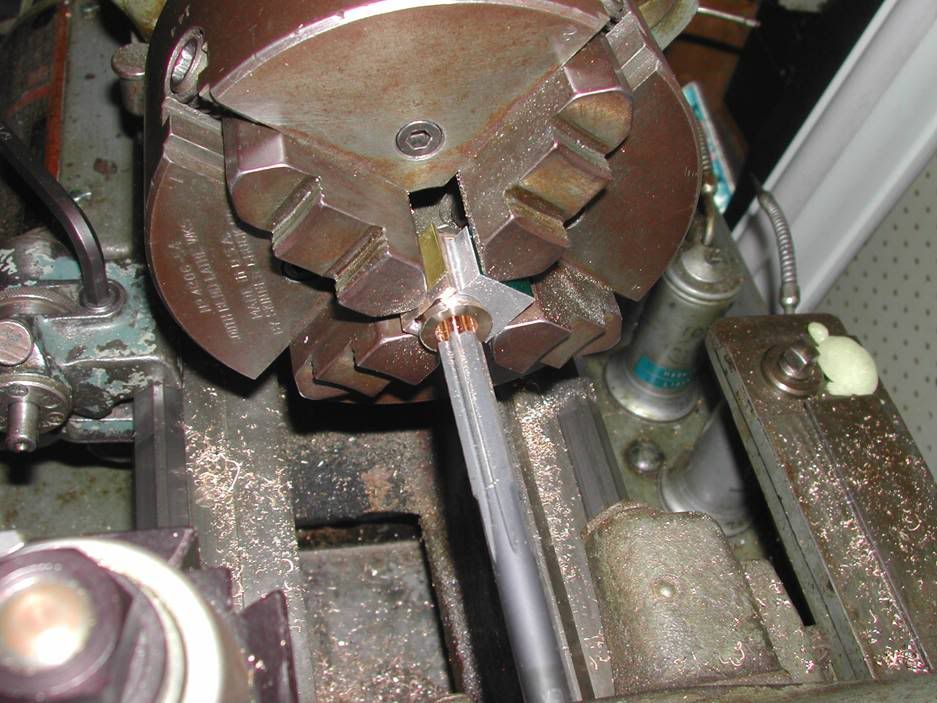

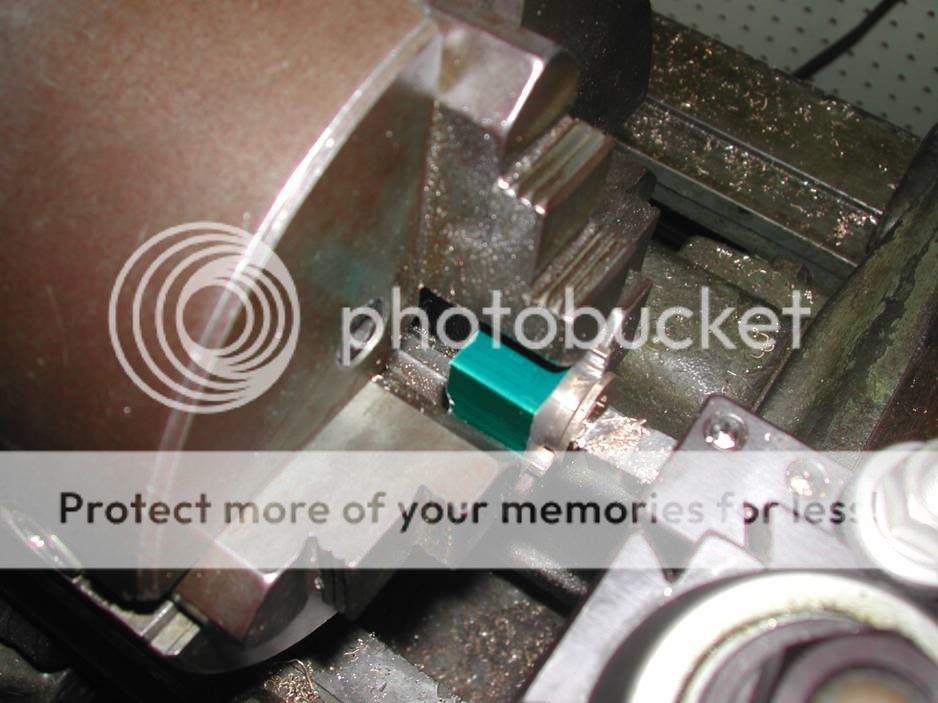

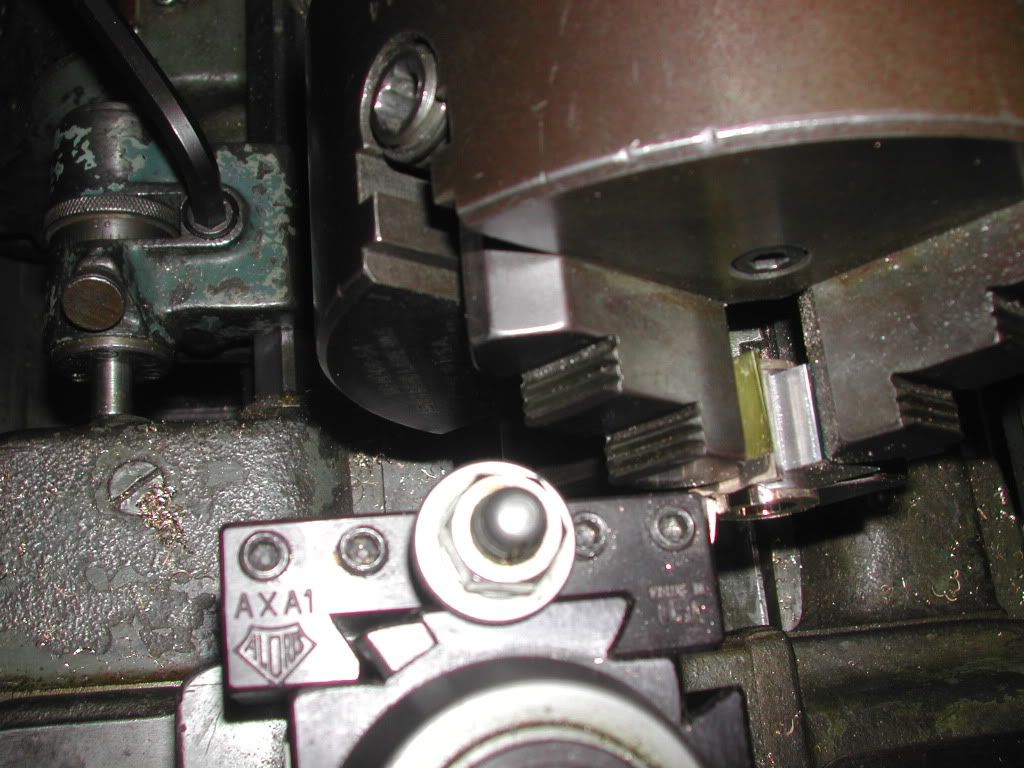

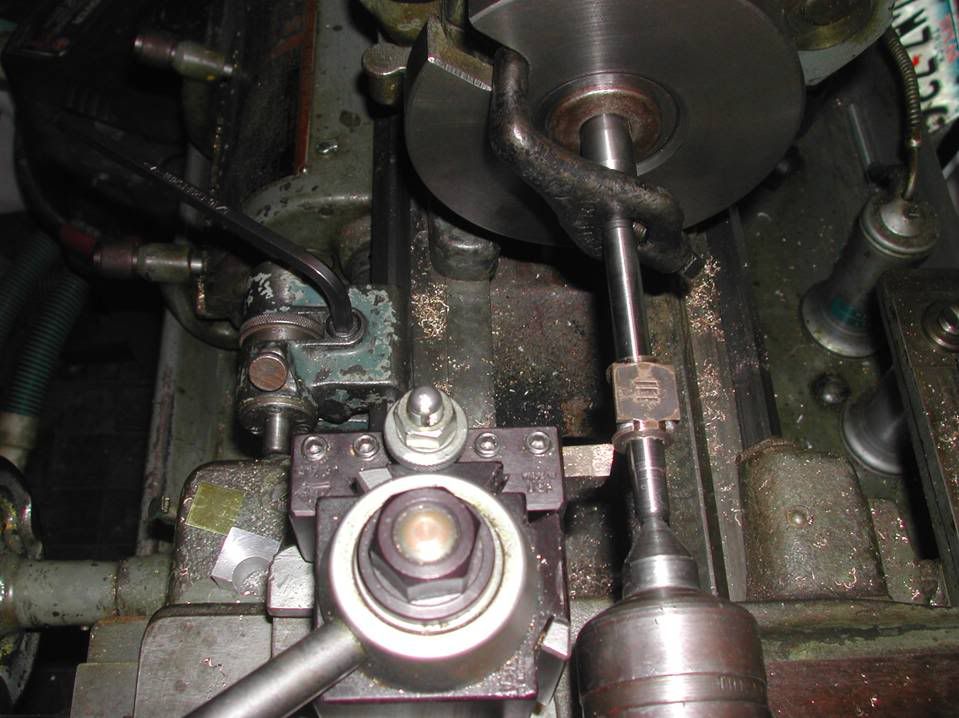

The port repair tool.

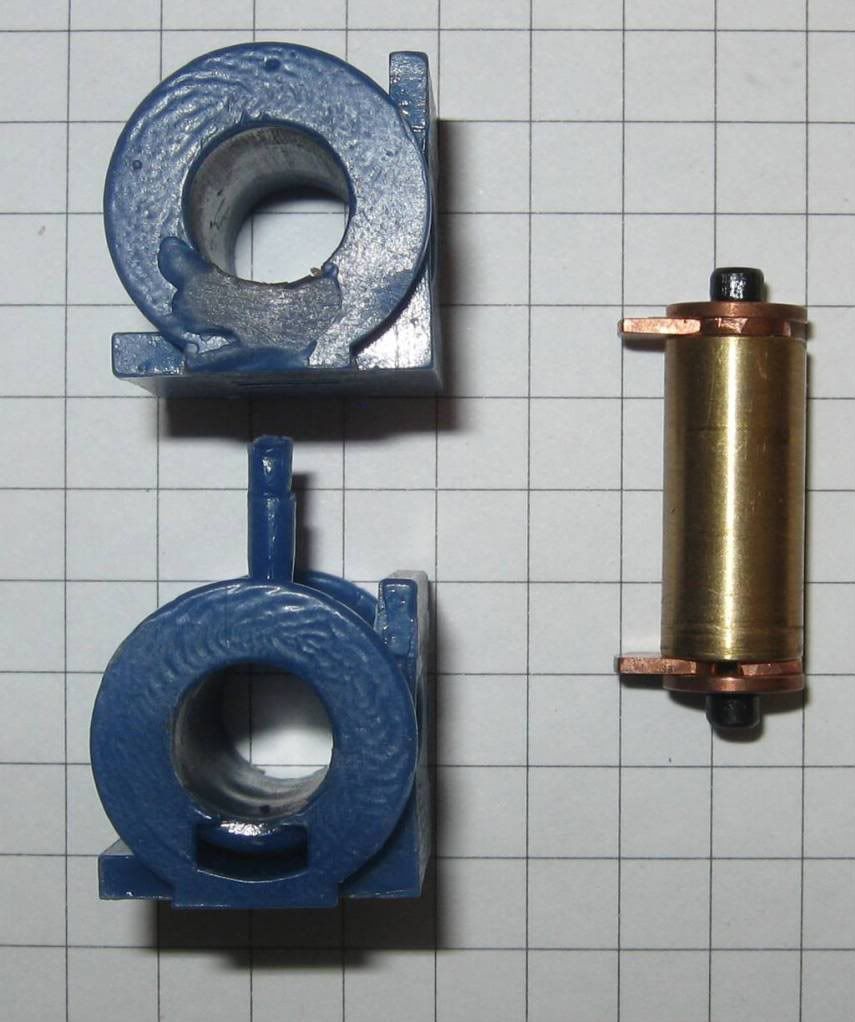

Test wax to show steam passages.

Bronze cylinder.

Dan

This is the metal wax injection mold with full steam passages. The injection point is rubber that I vulcanised in a bolt on part.

This is the other side.

The exploded view.

The port repair tool.

Test wax to show steam passages.

Bronze cylinder.

Dan