You're welcome, mate. I wish it were so easy for me. I'm looking to cut 14.5 PA gears for the old Drummond and for the worm gear on GHT's dividing head but do you reckon I can find cheap cutters for that? Pffft! Glad my researching helped somebody out anyway. Have fun making teeth!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bazmak - gearcutting

- Thread starter bazmak

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

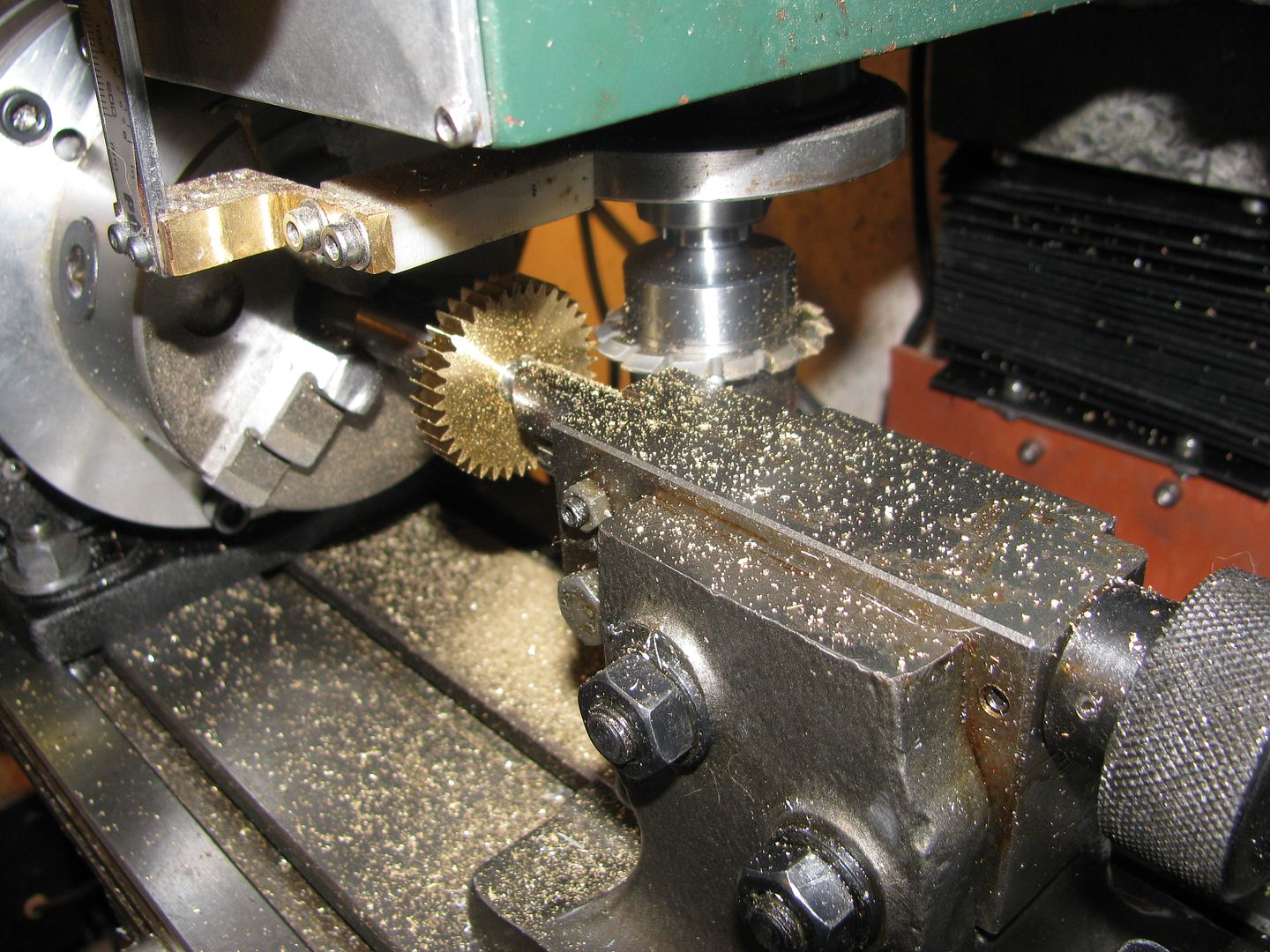

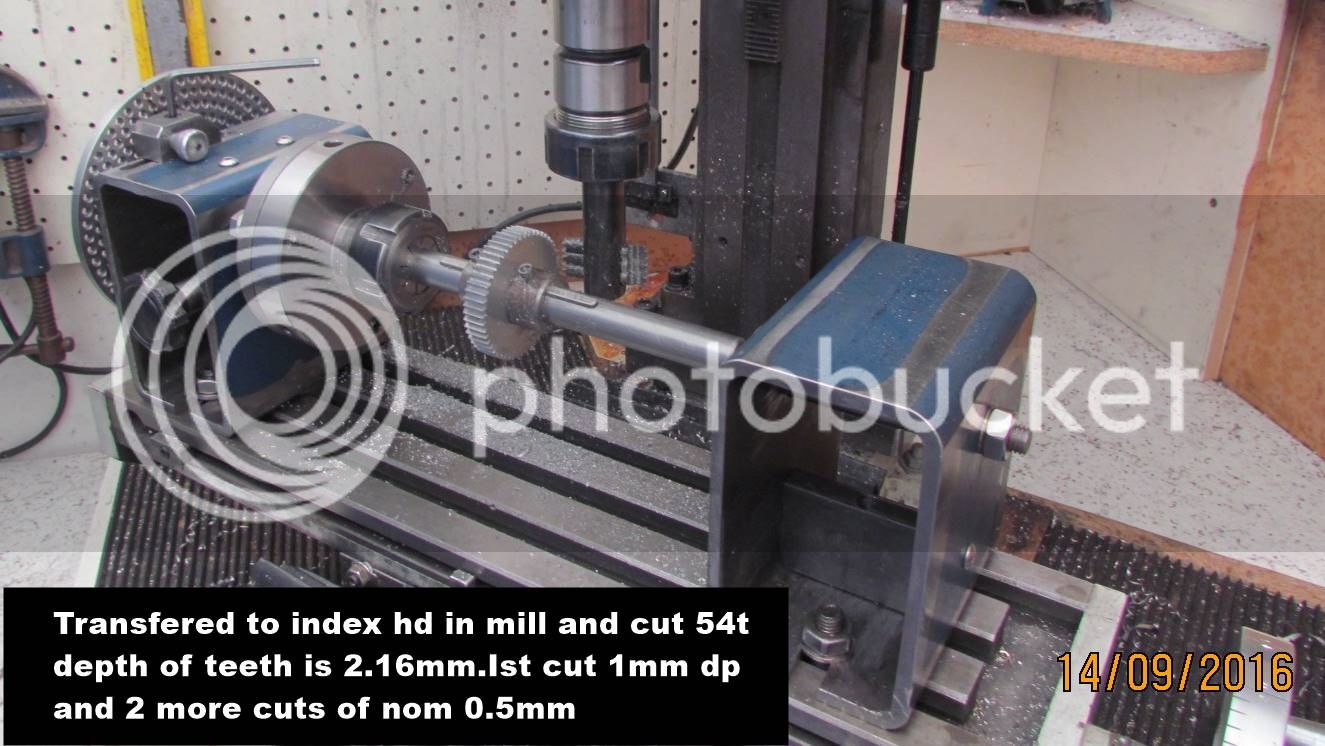

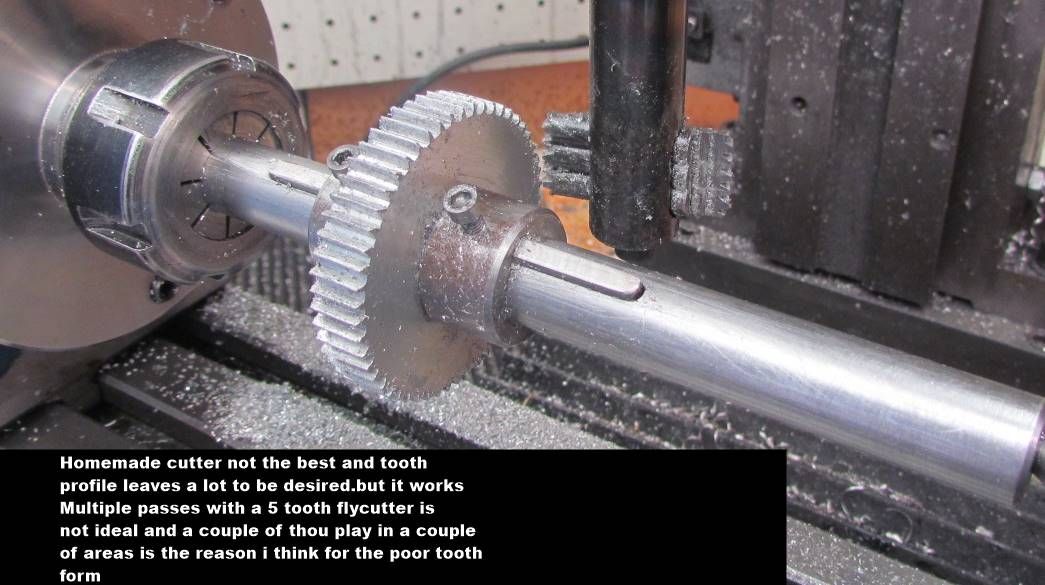

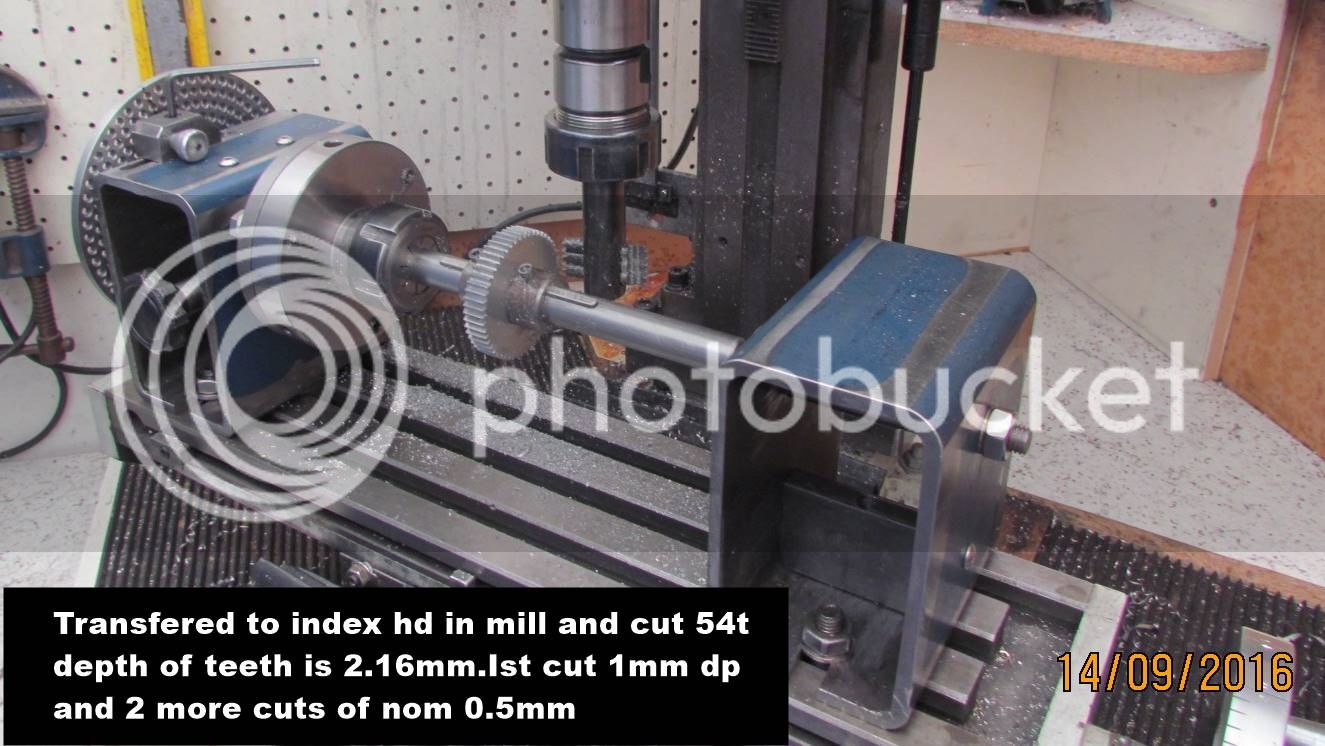

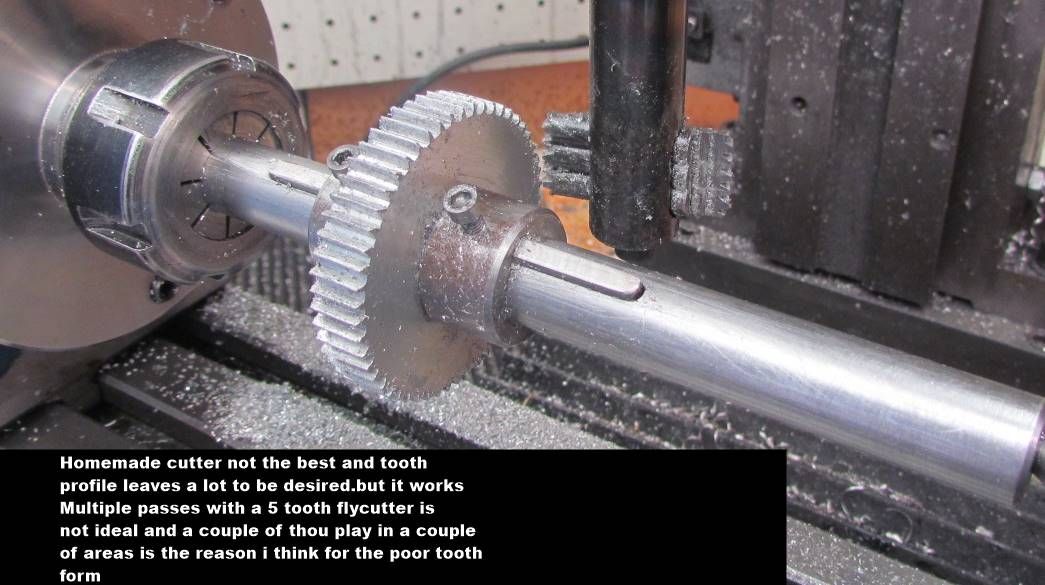

Correlated my indexing head with the other bits and pieces and cut my first gear.The 5t cutter works but not to a good enough standard.Homemade and having to

make multiple passes does not create a perfect tooth form.With a few thou play

in a couple of areas to be sorted and awaiting my order for some involute cutters before trying again,different materials etc.

Question. With my homemade cutter first pass was 1mm deep and then 2 more

to achieve 2.16mm tooth depth.Any comments ? should have made more lighter cuts or attemped 1 pass at full depth.

With the involute cutters cutting a full form single tooth ,should it be done in 1 pass or a no of smaller cuts. Obviosly multiple cuts accentuates and play in the index head.1 cut would be preferable but is the sieg mill rigid enough to cut

a full tooth form at a single pass with light feed ???

make multiple passes does not create a perfect tooth form.With a few thou play

in a couple of areas to be sorted and awaiting my order for some involute cutters before trying again,different materials etc.

Question. With my homemade cutter first pass was 1mm deep and then 2 more

to achieve 2.16mm tooth depth.Any comments ? should have made more lighter cuts or attemped 1 pass at full depth.

With the involute cutters cutting a full form single tooth ,should it be done in 1 pass or a no of smaller cuts. Obviosly multiple cuts accentuates and play in the index head.1 cut would be preferable but is the sieg mill rigid enough to cut

a full tooth form at a single pass with light feed ???

goldstar31

Well-Known Member

You're welcome, mate. I wish it were so easy for me. I'm looking to cut 14.5 PA gears for the old Drummond and for the worm gear on GHT's dividing head but do you reckon I can find cheap cutters for that? Pffft! Glad my researching helped somebody out anyway. Have fun making teeth!

Not wishing to spoil an excellent discussion, might I ask or comment but the old Drummond ( the RB) had 16DP gears and the GHT stuff( there was several) were 20DP- to mesh with Myford's 60 and 65 bullwheels.

Again, in Cleeve's Screwcutting in the Lathe,, he cut the gears with a sort of two ended flycutter made from a single hss lathe tool.

The stock answer is that :-

He hadn't a milling machine and he hadn't enough money to patent his swing tool. Oddly, his Myford was only half a Myford!

'Fraid his stuff is no longer available.

Barry, thank you for your tolerance- I hope

Norman

Cogsy

Well-Known Member

Baz,

I used a different looking tool to yours, made from drill rod with a series of 6 v's turned on the lathe then the diameter of the shank reduced to leave 5 upright v's. 4 longitudinal passes on the mill and a little clean-up filing and I had 4 sets of 'teeth'. Hardened than used like that. Anyway, I imagine they work the same, but mine did not have flats between the upright v's.

So the first pass, or passes, to full depth creates a full depth valley at the middle of the cutter and 2 smaller 'valleys' each side of the cutter. The next index of the blank should mean your cutter is now centered to cut on a valley that is already roughly half final depth, meanwhile the shallowest vally is deepened and the start of a new valley is made by the first tooth of the cutter (of course the trailing teeth on the cutter are making shallow forming cuts on the trailing valleys to approximate the involute form at the same time). So there isn't really a 'full depth' pass (unless you do it the very first cut that is). The only time I make multiple passes on a gear blank is when I index 3 extra teeth past one full turn so I can be sure all the teeth have had the extra 'forming' required by the trailing cutting teeth.

Hope this helps - it's easier than I make it sound.

I used a different looking tool to yours, made from drill rod with a series of 6 v's turned on the lathe then the diameter of the shank reduced to leave 5 upright v's. 4 longitudinal passes on the mill and a little clean-up filing and I had 4 sets of 'teeth'. Hardened than used like that. Anyway, I imagine they work the same, but mine did not have flats between the upright v's.

So the first pass, or passes, to full depth creates a full depth valley at the middle of the cutter and 2 smaller 'valleys' each side of the cutter. The next index of the blank should mean your cutter is now centered to cut on a valley that is already roughly half final depth, meanwhile the shallowest vally is deepened and the start of a new valley is made by the first tooth of the cutter (of course the trailing teeth on the cutter are making shallow forming cuts on the trailing valleys to approximate the involute form at the same time). So there isn't really a 'full depth' pass (unless you do it the very first cut that is). The only time I make multiple passes on a gear blank is when I index 3 extra teeth past one full turn so I can be sure all the teeth have had the extra 'forming' required by the trailing cutting teeth.

Hope this helps - it's easier than I make it sound.

Sorry I was unclear: yes two different sets/cutters for Drummond change gears and GHT's secondary wormwheel. 14DP and 32DP respectively but both are 14.5 deg pressure angle was what I meant.

I have since found RDG has 14.5 PA cutters that I had overlooked -- but at a price. $55 per cutter. A one off HSS flycutter is still on the cards at that price. Plus I don't want to wait three weeks or more for them to get here. Must reread Martin Cleeves' book and see how he did it. I figure making a template based on the button method of making gear cutters and freehand grinding and diamond filing a lathe tool blank to fit the button template.

Bazmak, (and Cogsy) I am still trying to figure out the geometry of the multi-tooth cutter you made. Is it made to a rack profile with straight sided teeth and you then move the gear blank around in tiny increments and take lots and lots of tiny cuts, sort of like on an old gear planer, thus doing away with indexing one tooth at a time while generating the involute curve as a series of tiny flats?

I have since found RDG has 14.5 PA cutters that I had overlooked -- but at a price. $55 per cutter. A one off HSS flycutter is still on the cards at that price. Plus I don't want to wait three weeks or more for them to get here. Must reread Martin Cleeves' book and see how he did it. I figure making a template based on the button method of making gear cutters and freehand grinding and diamond filing a lathe tool blank to fit the button template.

Bazmak, (and Cogsy) I am still trying to figure out the geometry of the multi-tooth cutter you made. Is it made to a rack profile with straight sided teeth and you then move the gear blank around in tiny increments and take lots and lots of tiny cuts, sort of like on an old gear planer, thus doing away with indexing one tooth at a time while generating the involute curve as a series of tiny flats?

goldstar31

Well-Known Member

Drummond gears are 14 DP 14.5 PA, made 100's of them including the tumbler reverse gears for the conversion that the Yahoo group did.

Might still have some tumbler reverse gears kicking about ?

Apologies John but I have both 'some' 14's and some 16s as well as a full set of 20's

Long time since I had a RB Drummond or a reliable memory:wall:

Regards

Norman

Regards

Norman

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

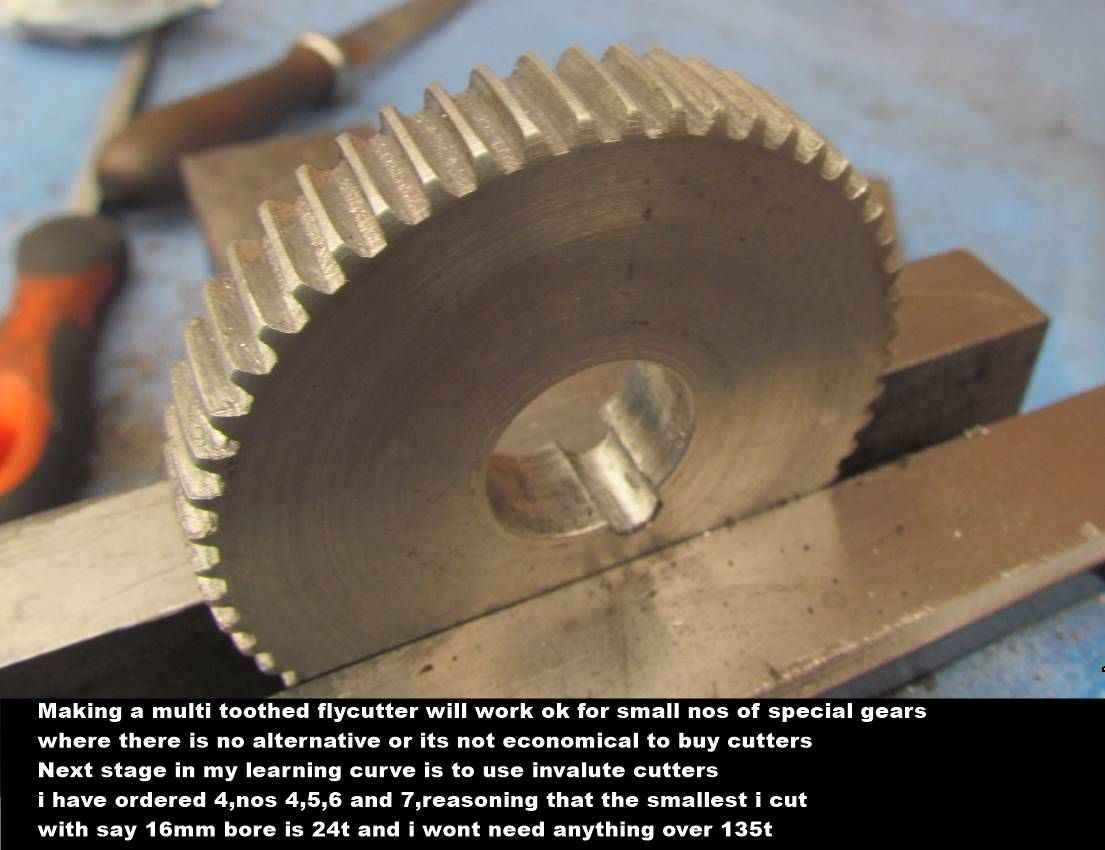

Hi Hopper,the 5 teeth are cut in this case at 40o included angle (2xPA) at a pitch of PI or 3.142mm,2.16mm deep to suit a rack profile

When I say 1pass I mean to the full depth in one cut which means the adjacent teeth are partially cut at the same time.I thought that the centre tooth cutting at full depth and the adj. teeth also being cut at the same pass

would be too heavy a cut.So I cut at 1mm depth and moved around 1 pitch at a time x 54 then moved the cutter I .5mm and did another 54 cuts before repeating again.A total of 162 cuts + an extra 3 at the end.Ball aching

Because its a homemade tool and there is a little play in the detent the cuts

were not as precise as I would have liked but in the end it did work

From what I understand as Cogsy explained to me is that the first cut

the centre tooth is cut as a rack form with adjacent teeth being part cut

when you move round 1 tooth it repeats so the adjacent teeth partially cut again to gradually form the involute shape.All simple clever stuff

When I say 1pass I mean to the full depth in one cut which means the adjacent teeth are partially cut at the same time.I thought that the centre tooth cutting at full depth and the adj. teeth also being cut at the same pass

would be too heavy a cut.So I cut at 1mm depth and moved around 1 pitch at a time x 54 then moved the cutter I .5mm and did another 54 cuts before repeating again.A total of 162 cuts + an extra 3 at the end.Ball aching

Because its a homemade tool and there is a little play in the detent the cuts

were not as precise as I would have liked but in the end it did work

From what I understand as Cogsy explained to me is that the first cut

the centre tooth is cut as a rack form with adjacent teeth being part cut

when you move round 1 tooth it repeats so the adjacent teeth partially cut again to gradually form the involute shape.All simple clever stuff

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Thanks Brian,that is the answer I was hoping for.The 24DP and .089" depth

are almost the same as MOD1.What size mill are you using? as machine rigidity

will also play a part.Will wait for the cutters to arrive before giving it a go

Congratulations on your project of the month.I have never attemped an IC engine,a little fazed by the electrics but you never know.I am confident

about making the mechanical parts but spark plugs etc uugg.I remember my first and only motor bike.A little 2 stroke BSA Bantam

Cogsy I can see how your tool works there is no need to machine the full acme

profile as the flats do not cut the work if the OD is correct.I also would have preferred to make from a solid dia piece of silver steel but the cost did not warrant it.1m of say 3/4" was over $100 plus my little MAP touch would not be man enough to harden a big lump.I have bought 4 involute cutters for $50

don't know what the quality will be,and I will have to make a holder for the mill

Maybe I can remove the collet chuck or boring head from the R8 spindle and make/screwcut an adaptor to fit??

are almost the same as MOD1.What size mill are you using? as machine rigidity

will also play a part.Will wait for the cutters to arrive before giving it a go

Congratulations on your project of the month.I have never attemped an IC engine,a little fazed by the electrics but you never know.I am confident

about making the mechanical parts but spark plugs etc uugg.I remember my first and only motor bike.A little 2 stroke BSA Bantam

Cogsy I can see how your tool works there is no need to machine the full acme

profile as the flats do not cut the work if the OD is correct.I also would have preferred to make from a solid dia piece of silver steel but the cost did not warrant it.1m of say 3/4" was over $100 plus my little MAP touch would not be man enough to harden a big lump.I have bought 4 involute cutters for $50

don't know what the quality will be,and I will have to make a holder for the mill

Maybe I can remove the collet chuck or boring head from the R8 spindle and make/screwcut an adaptor to fit??

I am using a "tabletop" mill, a CX601 by Busybee tools. Previously I used the same cutters on a CT129 mill from Busybee tools. It doesn't require a large mill to use these cutters. For specs on these mills, go to Busybeetools.com

Hi Bazmak, OK I see. It would cut the involute curve as a small number of flats, depending on how many teeth were engaged with the cutter at a time, it seems. I think if you indexed by less than one pitch (if you had infinite patience!) you would get a greater number of smaller flats, the way the old Sunderland gear planers did it, that would be a closer approximation of the true involute curve. Interesting.

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

Yes it seems to create a small no of flats which approximates the curve

However if you rotate by less than one pitch you would remove the tooth

However if you rotate by less than one pitch you would remove the tooth

Of course it would. I'll get my head around it eventually. Might have to give one of your cutters a try myself. Would be eaiser than trying to hand grind the involute curve on a 32 DP cutter - about 1/8" wide at the top of the teeth and with a depth even less. Getting pretty tiny to grind accurate curves.

Just thinking about it some more, it should be possible to make a single tooth flycutter to rack form and achieve a similar result to a three-tooth cutter by going around the gear and cutting the teeth to full depth in one go, then move the gear to the left by one rack pitch then go around again, then move the gear to the right one rack pitch past the original position and go around once more.

The second and third go arounds would in effect be cutting the same profile as the two outside teeth on a three-tooth cutter, thus giving the relief angle on the top halves of the teeth, as would be done by Cleeve's double-ended cutter that Norman referred to earlier.

Does this make sense? I know it is a lot of extra cutting, going around 60 teeth two extra times. But it allows the use of a single, very simple to make HSS toolbit ground to 29 degrees using an Acme gauge and does away with expensive silver steel lumps, or stacking smaller sections together and hoping they don't move under load.

As Cleeve says in one of his articles, the involute curve can be far from perfect and still function useably well in low-speed, low-load applications, so should be ok for a dividing head worm wheel. He in fact recommends just using a straight sided rack-form tooth for any gears 59T and upwards.

Just a thought.

The second and third go arounds would in effect be cutting the same profile as the two outside teeth on a three-tooth cutter, thus giving the relief angle on the top halves of the teeth, as would be done by Cleeve's double-ended cutter that Norman referred to earlier.

Does this make sense? I know it is a lot of extra cutting, going around 60 teeth two extra times. But it allows the use of a single, very simple to make HSS toolbit ground to 29 degrees using an Acme gauge and does away with expensive silver steel lumps, or stacking smaller sections together and hoping they don't move under load.

As Cleeve says in one of his articles, the involute curve can be far from perfect and still function useably well in low-speed, low-load applications, so should be ok for a dividing head worm wheel. He in fact recommends just using a straight sided rack-form tooth for any gears 59T and upwards.

Just a thought.

goldstar31

Well-Known Member

Of course, it isn't Hopper or even Cleeve. Gear cutting was done by chisel in the Middle Ages. No, the USA and Australia didn't have one . It was done in Germany by Johannes Gutenberg, a goldsmith who invented the printing press. No, we Brits didn't either. Sorry to spoil your day.

. It was done in Germany by Johannes Gutenberg, a goldsmith who invented the printing press. No, we Brits didn't either. Sorry to spoil your day.

There is a lot about how it was done and the BBC did a programme using Stephen Fry. There is a UTube or whatever you call it now on the topic. Incredible stuff, almost forgotten but that is what enabled us lowly mortals to 'read and write' instead of some lonely cleric with time on his lands-hands like the Venereal(?) Bede down the road at Jarrow.

For those with more of a sense of humour, TV has just repeated one of the Last of the Summer Wine series where the hapless trio in RDG Country get involved in an old mangle with- cast, cast iron gears.

Who says TV repeats are boring?

Another Norman

There is a lot about how it was done and the BBC did a programme using Stephen Fry. There is a UTube or whatever you call it now on the topic. Incredible stuff, almost forgotten but that is what enabled us lowly mortals to 'read and write' instead of some lonely cleric with time on his lands-hands like the Venereal(?) Bede down the road at Jarrow.

For those with more of a sense of humour, TV has just repeated one of the Last of the Summer Wine series where the hapless trio in RDG Country get involved in an old mangle with- cast, cast iron gears.

Who says TV repeats are boring?

Another Norman

Fluffy

Well-Known Member

G'Day All,

I thought that I would put my two bob's worth in here Re; homemade gear cutters. This method is not my idea, & it works very well.

I stumbled on this site a few years ago (www.metallmodellbau.de), while looking for ideas for homemade gear cutters. The article needed to be translated via Google translator for me to be able to read the more important parts of the text.

I found this method to be simple & very cost effective when considered to the price of gear milling cutters.

The multi tooth cutters have been turned & relieved from high carbon steel. Heat treated by using a gas flame & water quenched, then honed on the cutting surfaces. Important to note that the cutting face must be on the centreline of the blank.

The pitch of the teeth is calculated by multiplying the gear tooth module x pi, the included angle of the teeth is 40˚(for 20˚ pressure angle) & the depth calculated by multiplying the gear module x 2.25 + 0.05mm for 20˚ PA.

With the cutter held vertically, the centre of the cutter is centred on the dividing head height, the gear teeth are then cut to depth with several passes of the cutter. I used 4 cuts for a 1.5 module gear. As the cutter is cutting with several teeth at one time, an approximate involute form is cut via a numbers of small flats.

To further improve the profile of the teeth, I then made a simple jig & ran the gears together with 600 grit lapping paste in both directions until the work surface of the tooth looked OK.

I have used this method for a number of differing gear modules & all of the gears ran well in the required application with no excessive noise.

The two gears in the image are 0.6 module & were as test to try this method.

Don.

I thought that I would put my two bob's worth in here Re; homemade gear cutters. This method is not my idea, & it works very well.

I stumbled on this site a few years ago (www.metallmodellbau.de), while looking for ideas for homemade gear cutters. The article needed to be translated via Google translator for me to be able to read the more important parts of the text.

I found this method to be simple & very cost effective when considered to the price of gear milling cutters.

The multi tooth cutters have been turned & relieved from high carbon steel. Heat treated by using a gas flame & water quenched, then honed on the cutting surfaces. Important to note that the cutting face must be on the centreline of the blank.

The pitch of the teeth is calculated by multiplying the gear tooth module x pi, the included angle of the teeth is 40˚(for 20˚ pressure angle) & the depth calculated by multiplying the gear module x 2.25 + 0.05mm for 20˚ PA.

With the cutter held vertically, the centre of the cutter is centred on the dividing head height, the gear teeth are then cut to depth with several passes of the cutter. I used 4 cuts for a 1.5 module gear. As the cutter is cutting with several teeth at one time, an approximate involute form is cut via a numbers of small flats.

To further improve the profile of the teeth, I then made a simple jig & ran the gears together with 600 grit lapping paste in both directions until the work surface of the tooth looked OK.

I have used this method for a number of differing gear modules & all of the gears ran well in the required application with no excessive noise.

The two gears in the image are 0.6 module & were as test to try this method.

Don.

goldstar31

Well-Known Member

Might I add a bit of help to those whose German is somewhat limited?

Simply Google 'Metallmodellbau' and then 'translate this page' and it comes up in very good Englische.

I recall some very good stuff like the Bonelle tool and cutter grinder on the same site.

Thanks, Don, I'd forgotten its existence. Doing too much in Catalan and French but neither have owt to do with model engineering malarkey. My private Hell is yet to finish:fan:

Cheers

N

Simply Google 'Metallmodellbau' and then 'translate this page' and it comes up in very good Englische.

I recall some very good stuff like the Bonelle tool and cutter grinder on the same site.

Thanks, Don, I'd forgotten its existence. Doing too much in Catalan and French but neither have owt to do with model engineering malarkey. My private Hell is yet to finish:fan:

Cheers

N

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

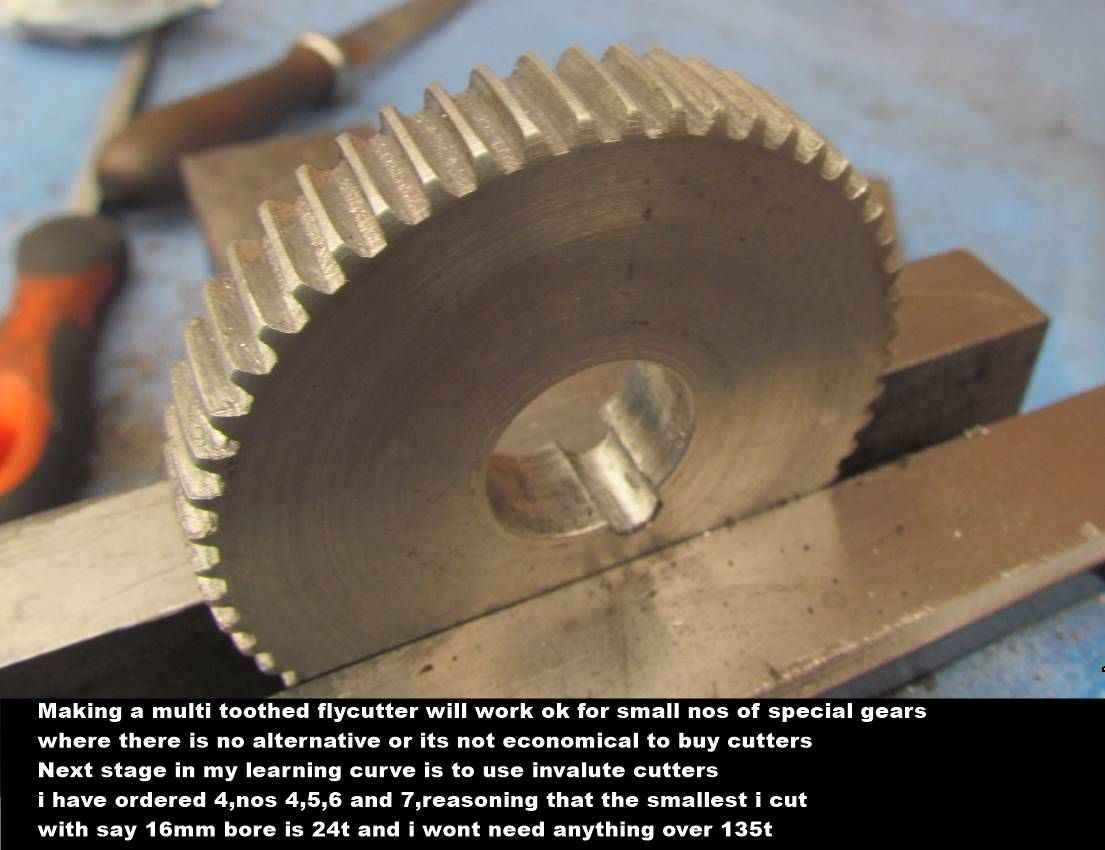

Well described Fluffy.Basically what I have achieved thru trial and error

From the book I worked the pitch for a mod1 as PI but the depth was

given as 2.16mm,your formula would give 2.3mm for mod1.Single tooth

flycutter not the best but all I could manage with max 10mm dia silver steel

Your cutters would be the next step up for me but I have decided to buy involute

cutters rather than larger silver steel.Its all a learning curve,thats why I am doing it.Thanks for your input

From the book I worked the pitch for a mod1 as PI but the depth was

given as 2.16mm,your formula would give 2.3mm for mod1.Single tooth

flycutter not the best but all I could manage with max 10mm dia silver steel

Your cutters would be the next step up for me but I have decided to buy involute

cutters rather than larger silver steel.Its all a learning curve,thats why I am doing it.Thanks for your input

- Joined

- Dec 12, 2012

- Messages

- 2,220

- Reaction score

- 1,285

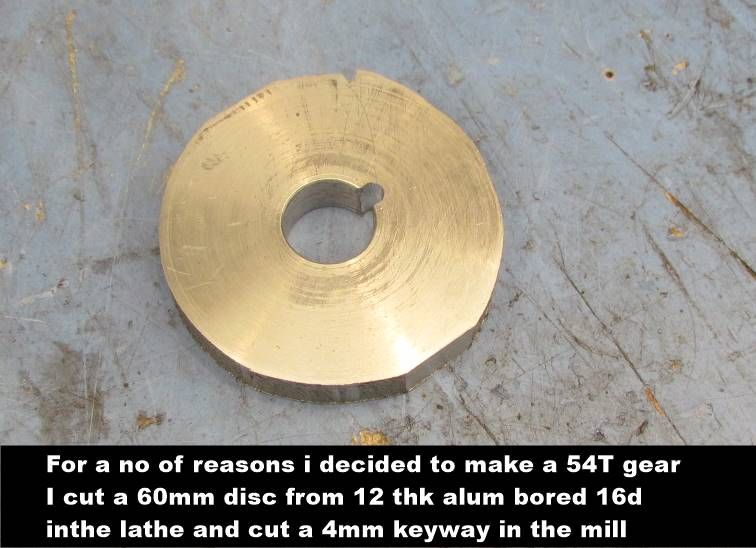

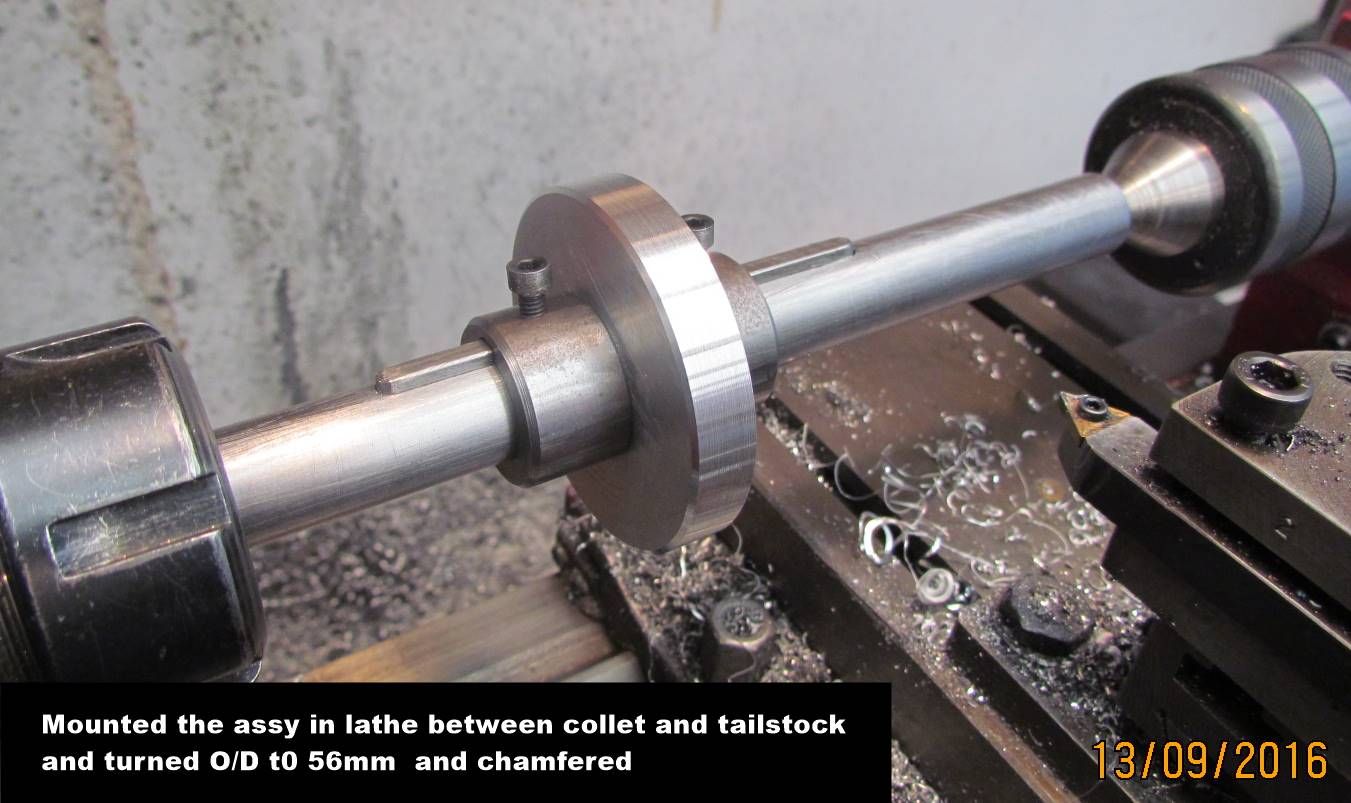

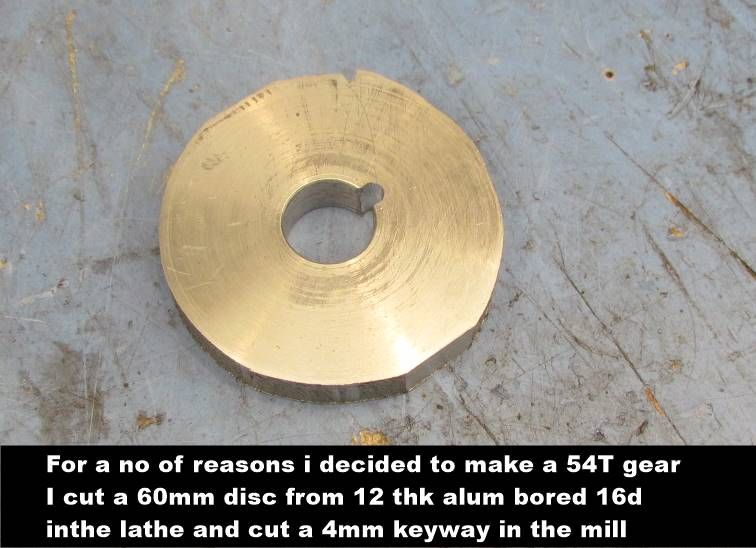

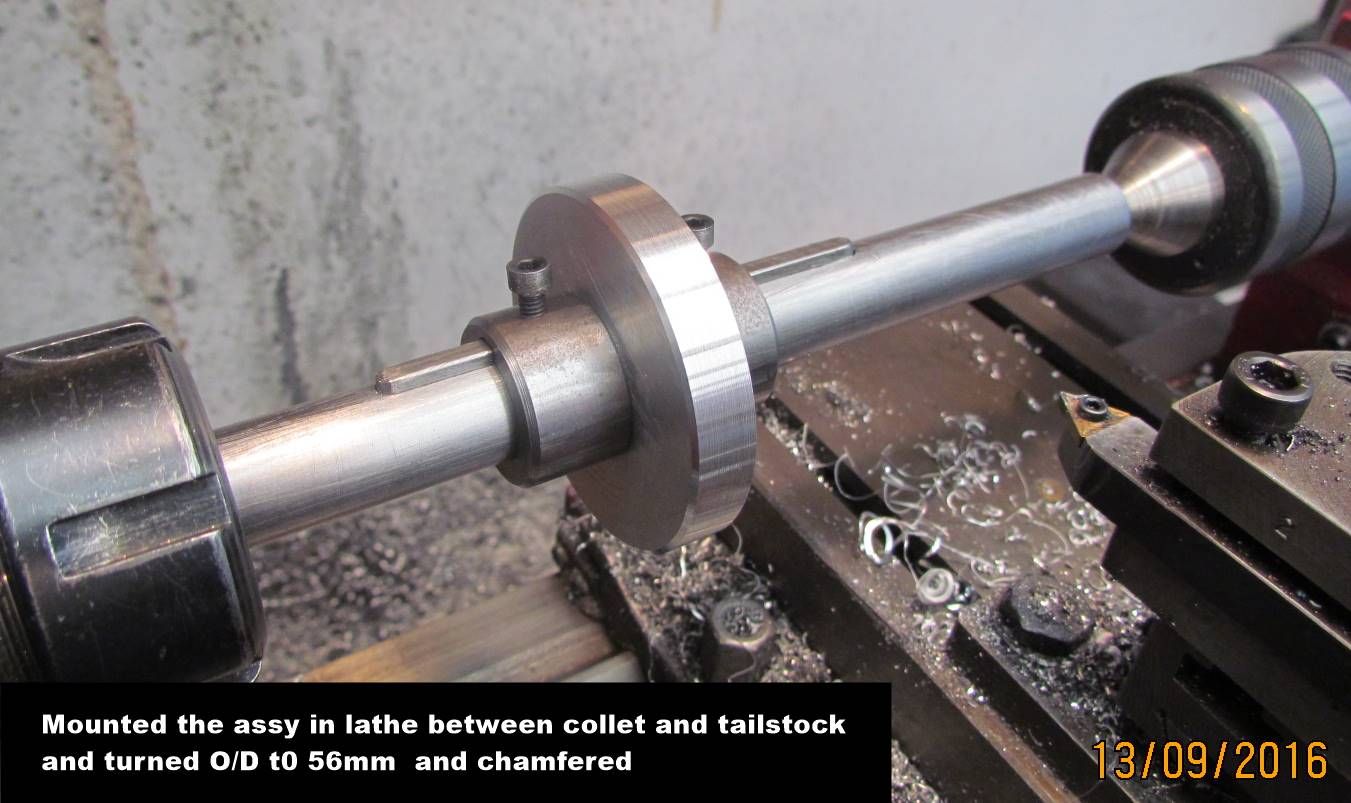

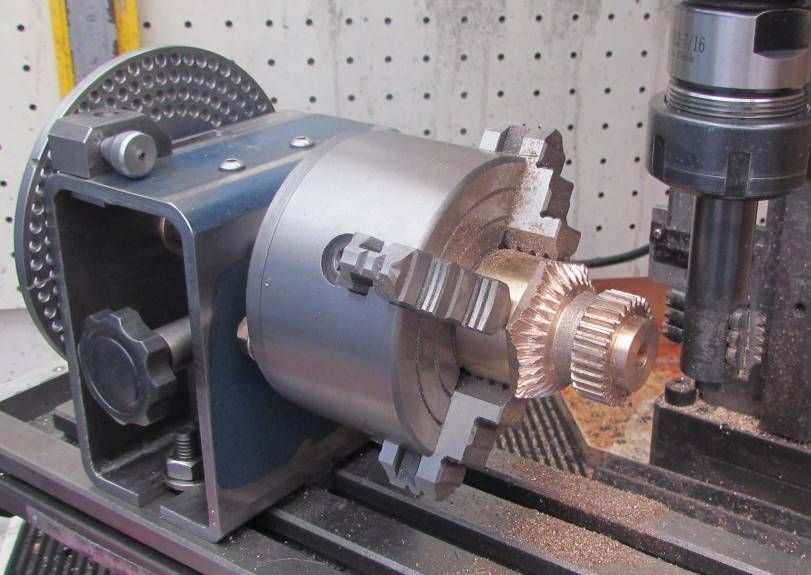

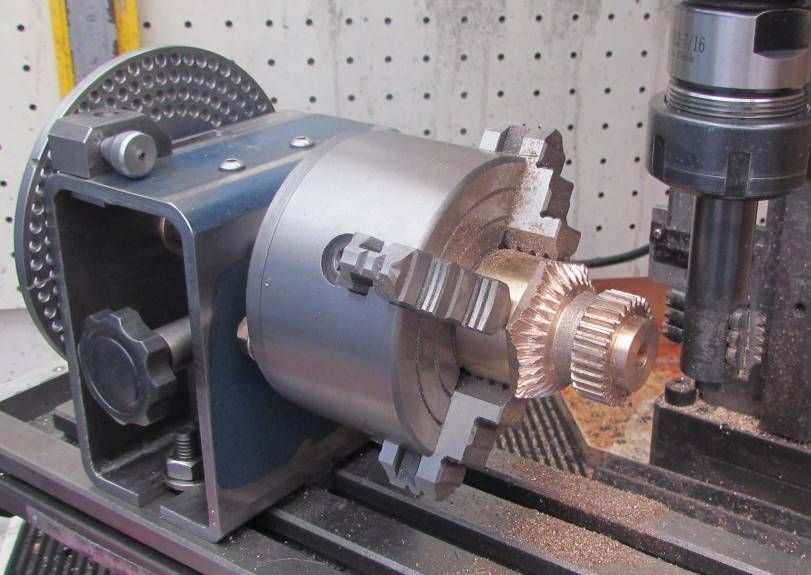

In order to speed up the learning curve,iron out minor niggles with the tool and index head,help out a friend who lives round the corner and to get

the required education to enable me to become a professional gear cutter

before I hit 85yrs.I accepted an order for 2 brass spur gears 15 and 30 T 24DP

I annealed my homemade 5T mod 1 (25.4DP) gear cutter and remachined to

to suit.3.3mm pitch and 2.35mm dp.I first tried cutting MS blanks but the cutter was not up to scratch.Remade and cut 2 brass blanks to supplied drg.Also made a small test jig for meshing and checking the centres.Everything to my satisfaction.The gears mesh well at +3thou centres and should be spot on

with a little titivation. Hope the client is happy.Learning all the t ime

ime

the required education to enable me to become a professional gear cutter

before I hit 85yrs.I accepted an order for 2 brass spur gears 15 and 30 T 24DP

I annealed my homemade 5T mod 1 (25.4DP) gear cutter and remachined to

to suit.3.3mm pitch and 2.35mm dp.I first tried cutting MS blanks but the cutter was not up to scratch.Remade and cut 2 brass blanks to supplied drg.Also made a small test jig for meshing and checking the centres.Everything to my satisfaction.The gears mesh well at +3thou centres and should be spot on

with a little titivation. Hope the client is happy.Learning all the t

ime

ime

Similar threads

- Replies

- 11

- Views

- 1K