Hi Fellas,

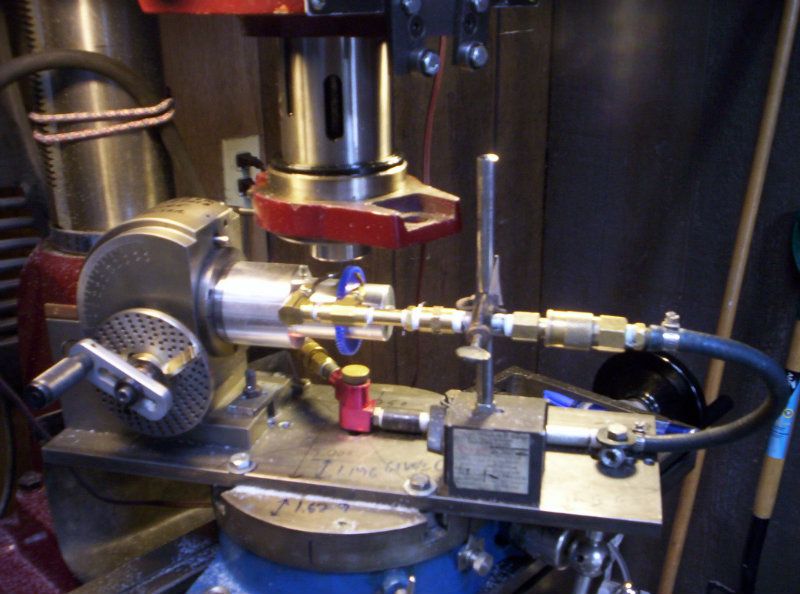

Nice to know I'm not the only sufferer from "Turbinitus" here. These things are very addictive, once you get started, you can't stop, I've got 3 of them now. The third one is in a small model gunboat which is radio controlled. Pretty appropriate I think, a bit of a tribute to Charles Parsons

http://en.wikipedia.org/wiki/Charles_Algernon_Parsons

I may make some more in the future and am considering making the Drawings and Materials available as a kit. but at the moment I'm thinking about making a different kind of turbine. I'm going to have a bash at at a minijet (Wren MW54 probably).

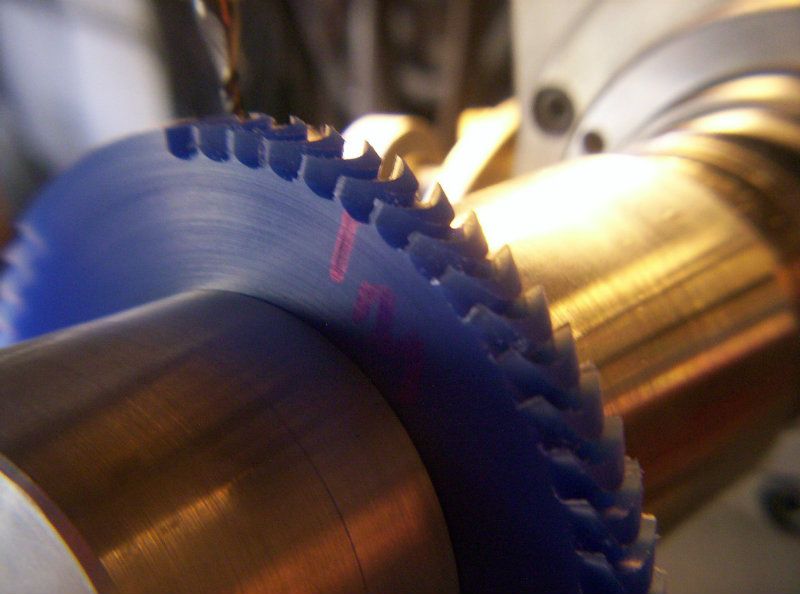

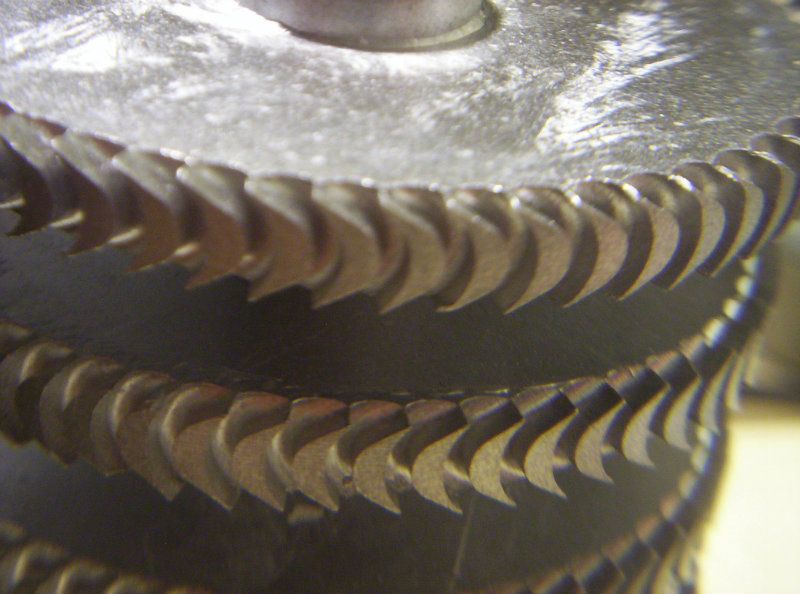

The rotors do take a fair amount of time to make (about 3 weeks in spare time moments) they are made from 2 sheets of thin brass with the blades on one offset tangentially by the thickness of the metal so they line up when riveted together. the brass is annealled (just like copper) and the blades dished slightly I have made a little punch and die for this. They are then twisted through 90 Deg. and the edges sharpened with a needle file. the two sheets are then riveted together. They are sandwiched between two collars whilst on the shaft and the whole thing riveted through this ensures the whole rotor is square to the shaft. A thin brass shroud is simply soft soldered to the outside. Voila there's your rotor.

I have a sneaky technique for balancing them which whilst not as good as proper dynamic balancing gives good results and needs minimal equipment. I simply clamp two woodsaw blades (any straight edges will do) in the vice with a block of wood between them. I then level them both lengthways and crossways and roll the rotor on it's shaft along them. It will tend to stop at one position with the heaviest part at the bottom. Scrape or grind a little material from the disk at this point (Dremel is handy for this) and repeat the process until the rotor stops at random and has no heavy point. It's a bit tedious but the degree of balance you can achieve is quite remarkable.

solarenergyadventures I do like your cast rotors they look a little like Stumpf type rotors but I think Stumpfs have a straight on admittance. Nozzle angle on mine is 30Deg similar to yours, as is the Diameter at 2¼". The speed is similar to yours running about 30,000 RPM On Load, off load speed is scary about 50,000 to 60,000 I think.

I hope to post some video shortly as a friend has just bought a little video camera and I'm sure he will oblige with a little footage.

Regards Mark