You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A3

- Thread starter 1hand

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Well, the book kinda starts with building the tender. I think the idea is to get the beginner builder going on easier work (it even says "first project for the beginner" right on the cover, though I'd suggest an oscillator or two firstkvom said:WRT the A3, it seems a lot of builders start with the tender. Personally I think building the loco first makes more sense as you could steam it with a makeshift tender while finishing the real tender.

From what I've read on different sites about the A3 in 1.5 is the tender slope and a place to ride. The length of the tender makes it hard to reach the controls if riding behind the tender. So if I was going to build in that scale I was going to change the shape of tender to be more square box looking to provide a place for your butt to sit, but I'm not building in that scale. :shrug:

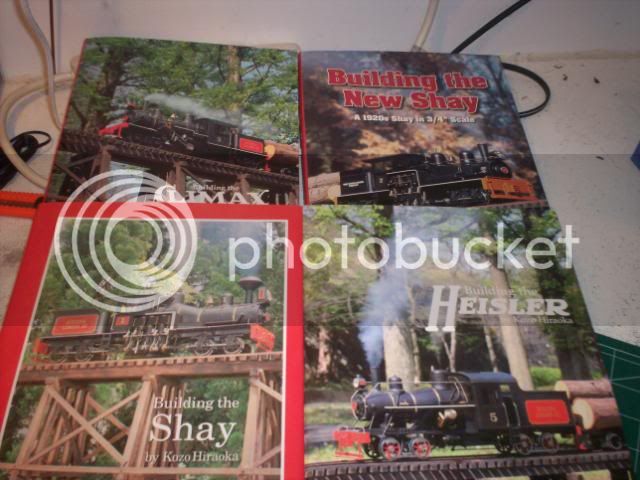

News flash..........the other 4 books are on the way. I should be tied up til about 2045 with projects now. Then I'll be 65 and probably settle down and build my first oscillator. That should take me the rest of the way through retirement. :

Matt

News flash..........the other 4 books are on the way. I should be tied up til about 2045 with projects now. Then I'll be 65 and probably settle down and build my first oscillator. That should take me the rest of the way through retirement. :

Matt

Well we are on page 4 already with this thread, I suppose we better get started.

I haven't counted all the parts that need to be made to complete the build, but we will keep a tally as we go.

Machining of A3 parts #1 thru #8.

Tender Wheels.

After getting the basic internal shape, We center drilled, drilled, and reamed to .3125

Matt

I haven't counted all the parts that need to be made to complete the build, but we will keep a tally as we go.

Machining of A3 parts #1 thru #8.

Tender Wheels.

After getting the basic internal shape, We center drilled, drilled, and reamed to .3125

Matt

Dan Rowe

Well-Known Member

- Joined

- Feb 12, 2010

- Messages

- 594

- Reaction score

- 18

Matt,

Nice collection of books I have the whole set except for the A3 book not shown.

I am building a scratch 7/8" scale Shay for G1 track using Lima Locomotive Works prints. I will start a thread on this effort soon.

Dan

Nice collection of books I have the whole set except for the A3 book not shown.

I am building a scratch 7/8" scale Shay for G1 track using Lima Locomotive Works prints. I will start a thread on this effort soon.

Dan

Any idea's on a finish I can use on the bare 12L14 wheels to keep them from rusting, but still keep the bare metal look? ???

Would an clear coat spray can work? Would that stick to the bare metal without the primer and paint?

Matt

Would an clear coat spray can work? Would that stick to the bare metal without the primer and paint?

Matt

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

1hand said:Any idea's on a finish I can use on the bare 12L14 wheels to keep them from rusting, but still keep the bare metal look? ???

Would an clear coat spray can work? Would that stick to the bare metal without the primer and paint?

Matt

Good question. I'll be interested in hearing more about that.

cl350rr said:what about nickel electroplating, if you don't buff it out it looks similar to machined steel. just a thought

Randy

Never heard of that. Whats involved? Expensive?

Thanks

Matt

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1hand said:Any idea's on a finish I can use on the bare 12L14 wheels to keep them from rusting, but still keep the bare metal look? ???

Would an clear coat spray can work? Would that stick to the bare metal without the primer and paint?

Matt

How about a parkerizing process? I use on steel parts and find it attractive. Very easy process to do for the average guy in a home shop, and not very expensive

http://en.wikipedia.org/wiki/Parkerizing

-MB

Metal Butcher said:How about a parkerizing process? I use on steel parts and find it attractive. Very easy process to do for the average guy in a home shop, and not very expensive

http://en.wikipedia.org/wiki/Parkerizing

-MB

MB do you have any pics of parts you have done? I read the link you posted, but could you kinda tell me about how you went about it and where you get the solution, how you heat it, and do you reuse it, or is it done after each part?

Thanks

Matt

Is this what you use?

http://www.homedepot.com/h_d1/N-5yc...splay?langId=-1&storeId=10051&catalogId=10053

Matt

http://www.homedepot.com/h_d1/N-5yc...splay?langId=-1&storeId=10051&catalogId=10053

Matt

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1hand said:Is this what you use?

http://www.homedepot.com/h_d1/N-5yc...splay?langId=-1&storeId=10051&catalogId=10053

Matt

No, no, That's not it. I'll get back to you on the previous post by you.

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1hand said:MB do you have any pics of parts you have done? I read the link you posted, but could you kinda tell me about how you went about it and where you get the solution, how you heat it, and do you reuse it, or is it done after each part?

Thanks

Matt

The stuff I use is Radocy brand by Raven enterprises. I have in a 32 oz. bottle. You mix it, 4 oz. to 1 gal. water. Heat in old stainless pot to 160+ degrees then add the pieces/parts for 15 to 20 minutes. Remove and rinse, when dry oil. It easier than making a cup of instant coffee!

One of Many sources.

http://www.amazon.com/dp/B000M66VYG/?tag=skimlinks_replacement-20

-MB

Last edited by a moderator:

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

Matt, yes I do re-use it until its spent.

In my picture post look at picture #2. I used it on other projects but its difficult to locate and provide links.

Since I don't know how, or post my own pictures, I can't post any other examples. The process gives a satin dark gray color.

http://www.homemodelenginemachinist.com/index.php?topic=8849.0

MB

In my picture post look at picture #2. I used it on other projects but its difficult to locate and provide links.

Since I don't know how, or post my own pictures, I can't post any other examples. The process gives a satin dark gray color.

http://www.homemodelenginemachinist.com/index.php?topic=8849.0

MB

Man thanks a Million for hooking me up. I really like the looks of that finish. Being most of my loco will be of steel may use that on the whole thing. Would give for a different look than what most do for a finish of painting black. It sounds like alot easier than painting also.

A few more questions:

1) Any bad fumes to worry about

2)any special prep to the parts "like wipe with mineral spirits first" or a light media or sand blast

3) do the parts have to be subspended, or can you just throw them in there to get a good even finish

4) do you treat the parts after like you would a gun "light coat of gun oil periodically"

5) do you get the same results with 12L14 and 1018 steel.

6) what about cast or durbar

7) I have a huge turkey cooker pot, but its aluminium, Work or no?

Sorry for all the questions!

Matt

A few more questions:

1) Any bad fumes to worry about

2)any special prep to the parts "like wipe with mineral spirits first" or a light media or sand blast

3) do the parts have to be subspended, or can you just throw them in there to get a good even finish

4) do you treat the parts after like you would a gun "light coat of gun oil periodically"

5) do you get the same results with 12L14 and 1018 steel.

6) what about cast or durbar

7) I have a huge turkey cooker pot, but its aluminium, Work or no?

Sorry for all the questions!

Matt

- Joined

- Dec 28, 2008

- Messages

- 1,731

- Reaction score

- 9

1hand said:Man thanks a Million for hooking me up. I really like the looks of that finish. Being most of my loco will be of steel may use that on the whole thing. Would give for a different look than what most do for a finish of painting black. It sounds like alot easier than painting also.

A few more questions:

1) Any bad fumes to worry about

2)any special prep to the parts "like wipe with mineral spirits first" or a light media or sand blast

3) do the parts have to be subspended, or can you just throw them in there to get a good even finish

4) do you treat the parts after like you would a gun "light coat of gun oil periodically"

5) do you get the same results with 12L14 and 1018 steel.

6) what about cast or durbar

7) I have a huge turkey cooker pot, but its aluminium, Work or no?

Sorry for all the questions!

Matt

1) Not that I know of. But read and follow the instructions that will be included with the product

2) degrease thoroughly, and do not touch with your fingers afterward, even if you wash them.Blasting with media is to add texture not intended as a way to clean the surface (the media might be contaminated).

3) must be suspended with wire to get the solution evenly all around the part.

4) yes, oil initially and wipe on a little after you handle the part, just to be sure.

5) I haven't tried it on 12L14 but I think it should work.

6)I haven't tried it on cast iron but I think it should work.

7) No aluminum. You must use a stainless steel pot and anything that will touch the solution.

I use a cheap garage sale 2 QT pot with handle , heat on K-stove, check with a thermometer and turn the heat off when it reaches 180-D, click heat back on when the temp drops to 160-D. Its very easy to do with just a few basic rules to get an even finish

Best time for parkerizing is when "Honey" is out and about! ;D

-MB

FWIW, there's also a Manganese Phosphate parkerizing option-- it's less seen but makes for a charcoal black color instead of gray. Pretty much the same method of application--- dunk into solution, wait. oil.

I've heard of people painting right after parkerizing since it leaves lots of little pores to grab and hold paint very well.

I've heard of people painting right after parkerizing since it leaves lots of little pores to grab and hold paint very well.

Similar threads

- Replies

- 3

- Views

- 919