You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A Stuart Turner Triple Expansion Engine

- Thread starter Hilmar

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

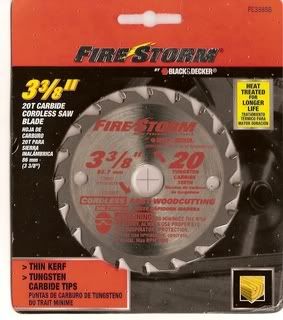

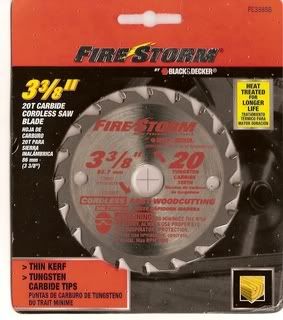

..please let me know something more about the Carbide blade who you bought from Home Depot ..like..number of tooth..diameter...Etc. TY

Paolo

Give me A Day or so, I will check tomorrow at home.

Hilmar

Paolo,

This is the blade I use. The best thing I ever bought to cut metal

It is by > LOWE'S < not Home Depot. $7.95. 3 3/8 diameter. The arbor hole is 15 mm

On my blade the kerf is 0.055 -0.060 thin. I run the blade on a Mini Mill.

I find that when I run it slow it will no work so good,it clogs and you can hear it, so I up the rpm to 800 - 1000 on Steel. Cutting fluid from Home Depot in the pluming Dep. On Alu and Brass Kerosene or dry and even more speed. The kerf is as smoth to be used directly

and no wandering.

Hilmar

This is the blade I use. The best thing I ever bought to cut metal

It is by > LOWE'S < not Home Depot. $7.95. 3 3/8 diameter. The arbor hole is 15 mm

On my blade the kerf is 0.055 -0.060 thin. I run the blade on a Mini Mill.

I find that when I run it slow it will no work so good,it clogs and you can hear it, so I up the rpm to 800 - 1000 on Steel. Cutting fluid from Home Depot in the pluming Dep. On Alu and Brass Kerosene or dry and even more speed. The kerf is as smoth to be used directly

and no wandering.

Hilmar

loggerhogger

Active Member

- Joined

- Jul 26, 2007

- Messages

- 36

- Reaction score

- 2

Hil. On the cylinder, can you build it up with some cast iron rod and a OA torch and then re-machine?

bigmartinmachine

New Member

- Joined

- May 4, 2009

- Messages

- 1

- Reaction score

- 0

On discussions regarding machining the crankshaft of a Sturt triple. I put mine in a dividing head with the type of spacers other people described and milled it. Much likely to pretzel it

K

Kermit

Guest

When you mentioned the crank doesn't line up with the center of the cylinders.....

Would it be easier to remake two of your piston rod connections? Leaving the center one alone and adding offset to the outside ones?

Is something like that possible with the room available, above the crank and between the supports?

Kermit

Would it be easier to remake two of your piston rod connections? Leaving the center one alone and adding offset to the outside ones?

Is something like that possible with the room available, above the crank and between the supports?

Kermit

Milan Machine Worrks

Active Member

- Joined

- Aug 23, 2009

- Messages

- 30

- Reaction score

- 7

I talked Cole Power Models today an ordered a set of drawing for the triple and at the same time I asked them about the castings being available separately and availability and they have the cylinder in stock.

GWRdriver

Senior Member

- Joined

- Jan 22, 2009

- Messages

- 721

- Reaction score

- 109

This is an interesting and informative thread. I have a set of Triple cylinder castings (but those are way down the to-do list) and years ago I became an advocate of built-up crankshafts, and not the brazed-up variety. I became this way after my 4th attempt to turn the crankshaft of my first engine build (a Stuart 10V) from the old Stuart drop-forged steel blank and succeeding only in making pretzels. I may have even kept one as a souvenier. Now my first option is always drill rod or SS and Loctite.

On Stuart casting quality, . . .When Hilmar bought his castings they would no doubt have come from the old Henley High Street shop and foundary. So far as I've ever heard or experienced those were invariably superb castings and these days some castings hunters especially value sets of the old castings. In addition, the old Stuarts would replace any casting which was not up to snuff. I never recall having to send for a replacement. But that was then, this is now. The castings from the current owners of Stuart Models are unfortunately earning a reputation for inconsistent quality, typically areas of hardness, which I've personally experienced lately, which is what the original Stuarts strove to eliminate. But it's the natue of the beast, small thin or delicate castings in iron are always more susceptable to spotty hardening.

On Stuart casting quality, . . .When Hilmar bought his castings they would no doubt have come from the old Henley High Street shop and foundary. So far as I've ever heard or experienced those were invariably superb castings and these days some castings hunters especially value sets of the old castings. In addition, the old Stuarts would replace any casting which was not up to snuff. I never recall having to send for a replacement. But that was then, this is now. The castings from the current owners of Stuart Models are unfortunately earning a reputation for inconsistent quality, typically areas of hardness, which I've personally experienced lately, which is what the original Stuarts strove to eliminate. But it's the natue of the beast, small thin or delicate castings in iron are always more susceptable to spotty hardening.

Alec Ryals

Well-Known Member

- Joined

- May 3, 2012

- Messages

- 154

- Reaction score

- 81

Nice Work, Im making the ectrincs now and cant tell if the 30* degree one is for the L.P. cylinder or the H.P. ?

Any thought would be of Great help.

Thank You

Alec Ryals

Any thought would be of Great help.

Thank You

Alec Ryals

Mechanicboy

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 957

- Reaction score

- 345

Nice Work, Im making the ectrincs now and cant tell if the 30* degree one is for the L.P. cylinder or the H.P. ?

Any thought would be of Great help.

Thank You

Alec Ryals

See post #95, page 10 in this the link http://www.homemodelenginemachinist.com/showthread.php?p=260466#post260466

On Stuart casting quality, . . .When Hilmar bought his castings they would no doubt have come from the old Henley High Street shop and foundary. So far as I've ever heard or experienced those were invariably superb castings and these days some castings hunters especially value sets of the old castings. In addition, the old Stuarts would replace any casting which was not up to snuff. I never recall having to send for a replacement. But that was then, this is now. The castings from the current owners of Stuart Models are unfortunately earning a reputation for inconsistent quality, typically areas of hardness, which I've personally experienced lately, which is what the original Stuarts strove to eliminate. But it's the natue of the beast, small thin or delicate castings in iron are always more susceptable to spotty hardening.

This may now be out of date since the company was taken over again

oh, something like three years ago. At a show the new owners told me the had to throw out about half the stock of castings they bought.

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 2

- Views

- 2K