robcas631

Well-Known Member

Beautiful engine!

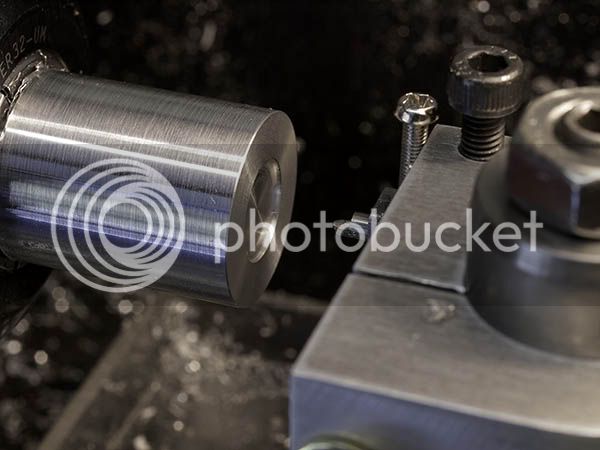

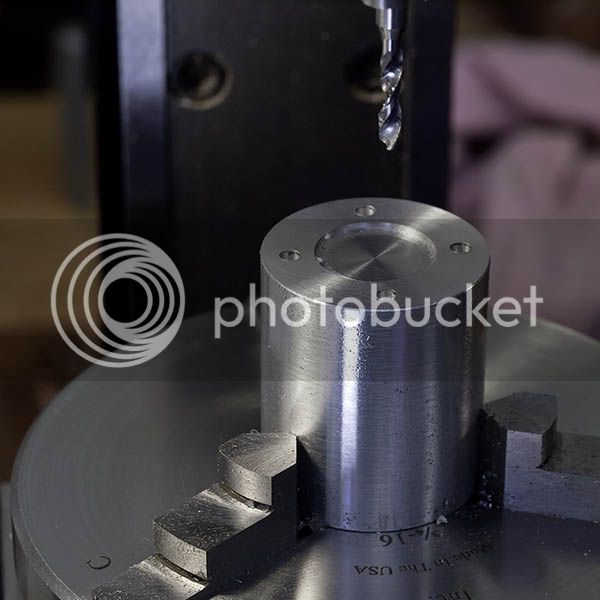

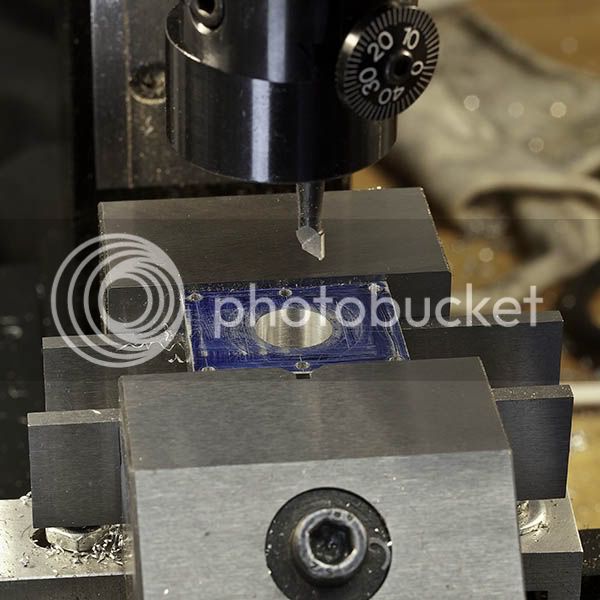

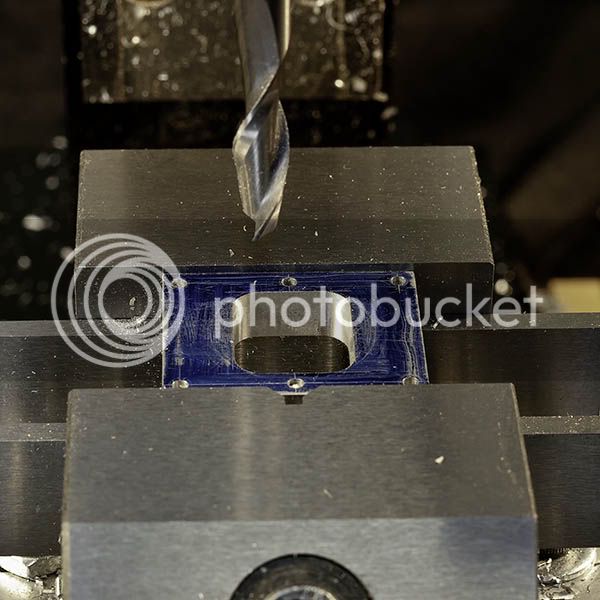

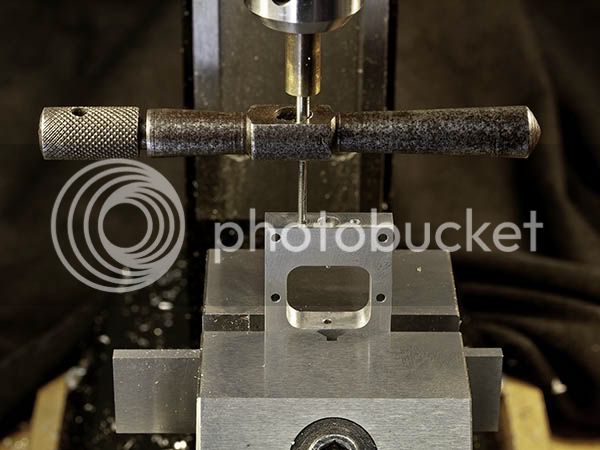

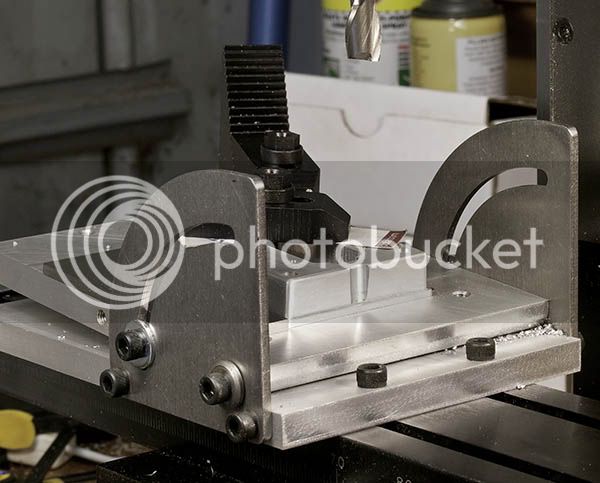

Thanks Todd, the large body does indded rotate on the 3/8" diameter pin. The spigot on the front of the large cylider has a flat on it to take the grub screw from the die holder. The short die holders are quicker to make and save material realtive to making the holder in one piece. Each time I make a piece of tooling I feel more comfortable in my shop

Enter your email address to join: