Kaleb

Senior Member

- Joined

- Jan 3, 2010

- Messages

- 272

- Reaction score

- 27

Not too long ago I stumbled upon a journal article detailing a liquid-piston steam engine which did away with the need for a boiler in the traditional sense. Following this up led me to some patent documents filed by a group of Japanese engineers working for Denso that details the working principle and basic layout of said engine. Here's a link to one of the patent documents if any of you are interested: https://patents.google.com/patent/US6931852B2/en

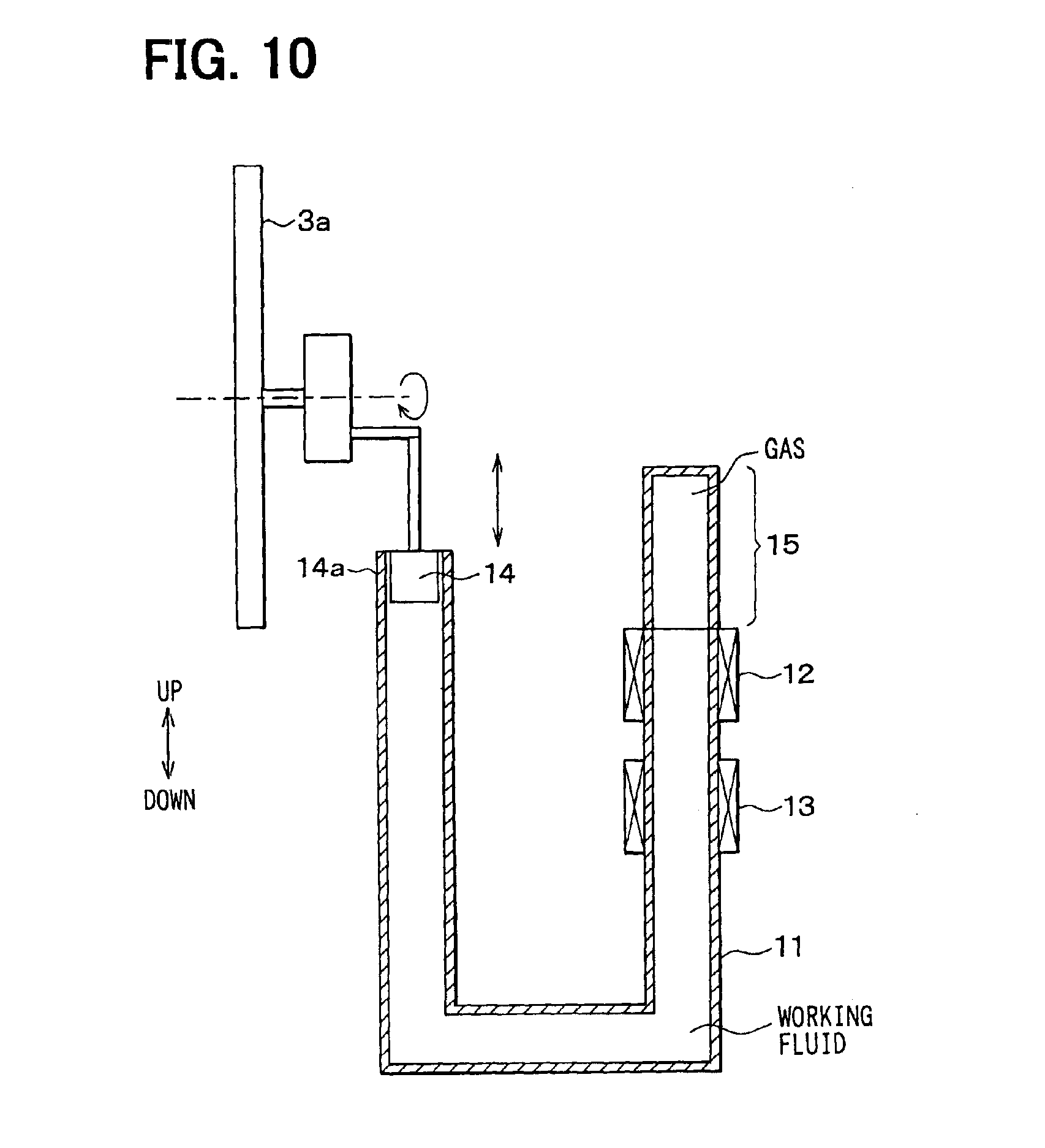

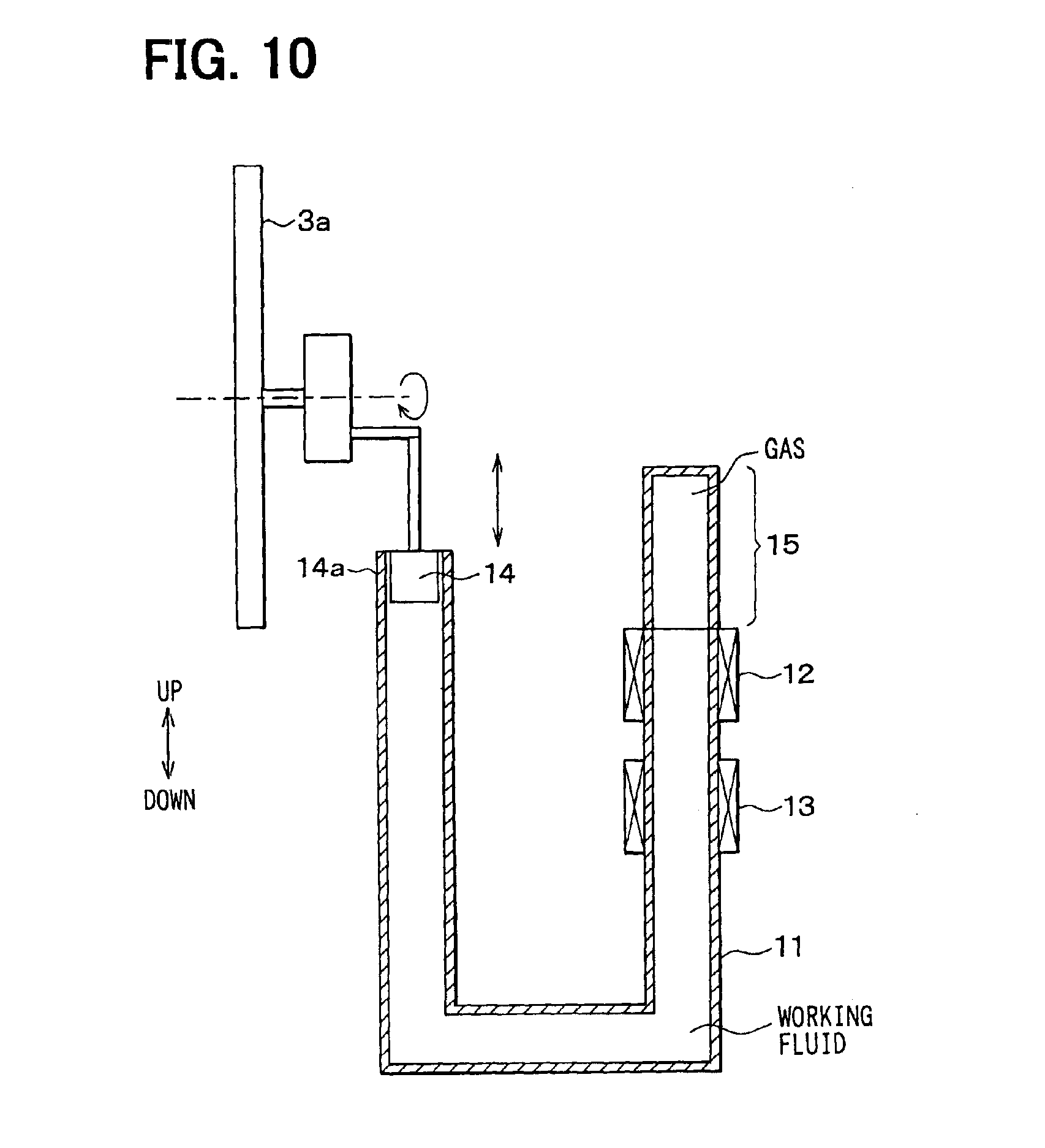

The basic layout of this engine can be seen in this patent drawing:

Modus operandii: When the piston 14 moves down, the working fluid (assumed to be water) is displaced upwards in tube 11 until it reaches the heated section at 12, at which point the liquid boils, increasing the pressure and pushing the rest of the water down, which in turn pushes the piston upwards. In doing so the water/steam boundary drops to a point where the steam comes into contact with the cooler at 13 which, since it is kept below the boiling point of water, causes it to condense again, reducing the pressure and allowing the piston at 14 to move down again and repeat the cycle.

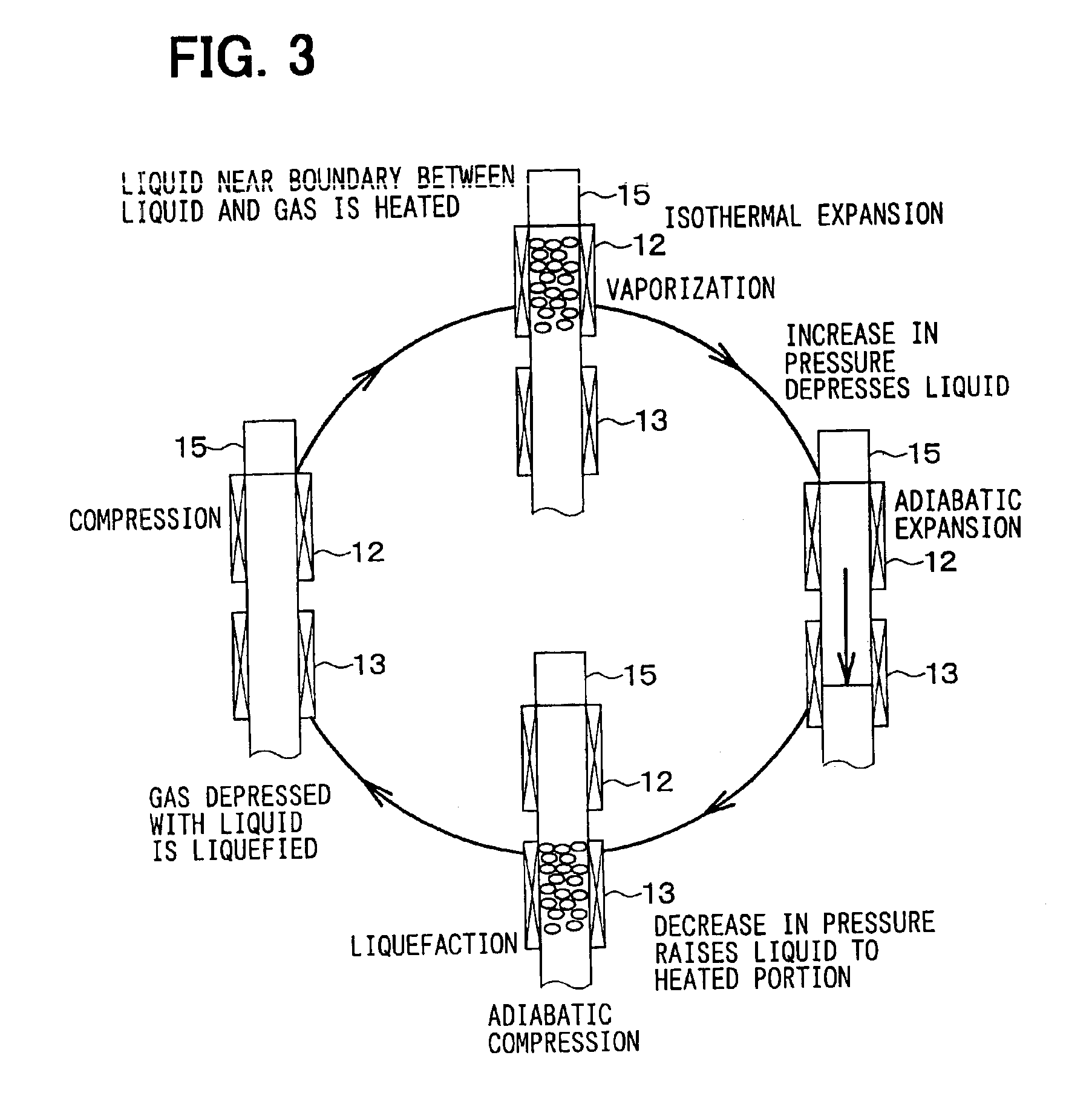

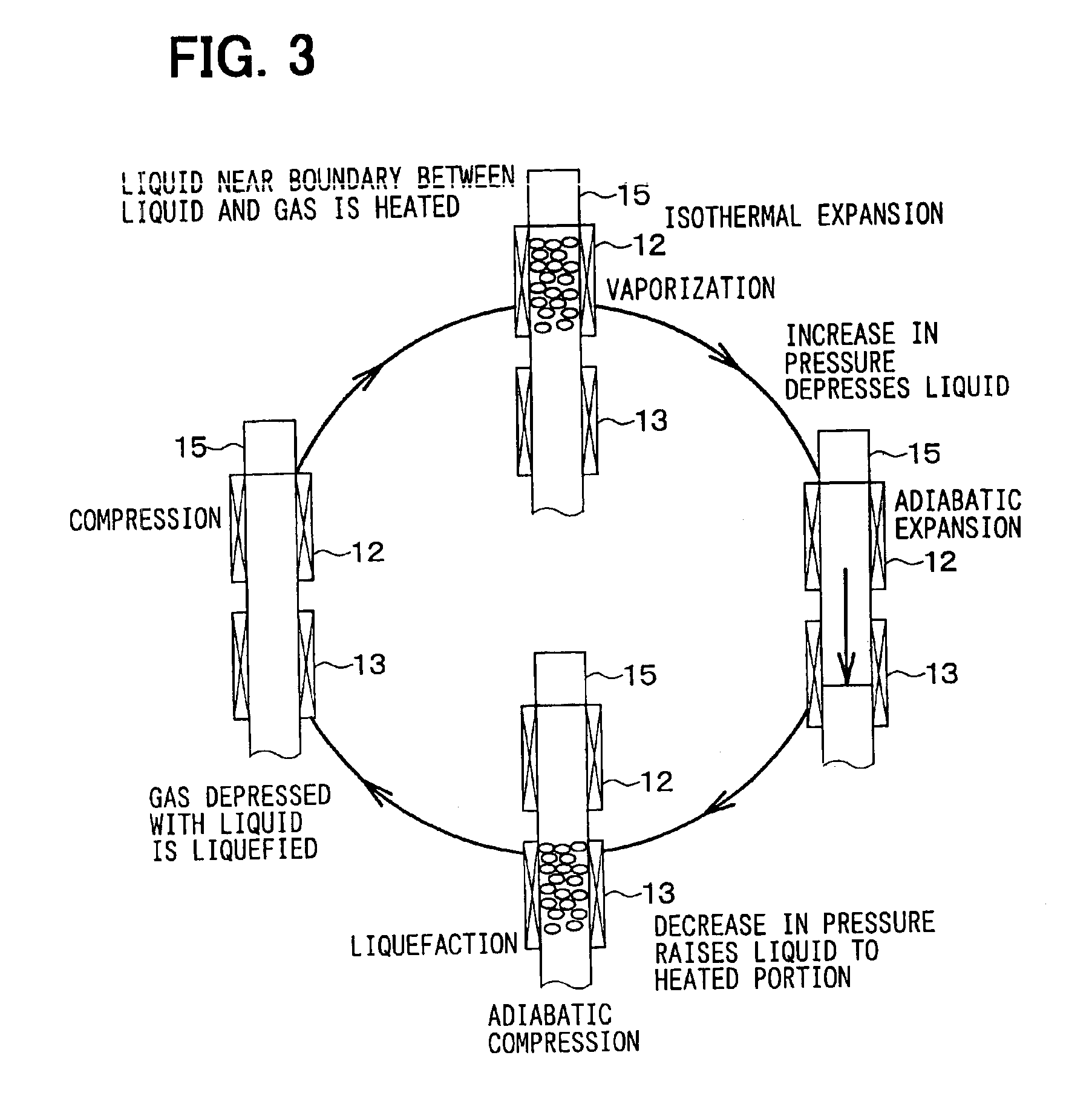

This additional patent drawing should hopefully make the working principle clearer.

For those of you who didn't know, the term "adiabatic" in this case basically means that, in theory at least, there is no transfer of heat or matter between the engine and its surroundings, that is to say energy is introduced or dissipated solely as mechanical work. In practice however nothing is perfect; there will always be some heat losses etc; but (hopefully) you get the idea.

Even if the principles still seem clear as mud as you read this, you should hopefully be able to see that this is an incredibly simple way of making an engine; which of course made me think "Can I get this to work? One way to find out, let's build it!". I checked the status of the patent, and it seems to have expired as of 2016, so I'm (hopefully) in the clear.

The basic layout of this engine can be seen in this patent drawing:

Modus operandii: When the piston 14 moves down, the working fluid (assumed to be water) is displaced upwards in tube 11 until it reaches the heated section at 12, at which point the liquid boils, increasing the pressure and pushing the rest of the water down, which in turn pushes the piston upwards. In doing so the water/steam boundary drops to a point where the steam comes into contact with the cooler at 13 which, since it is kept below the boiling point of water, causes it to condense again, reducing the pressure and allowing the piston at 14 to move down again and repeat the cycle.

This additional patent drawing should hopefully make the working principle clearer.

For those of you who didn't know, the term "adiabatic" in this case basically means that, in theory at least, there is no transfer of heat or matter between the engine and its surroundings, that is to say energy is introduced or dissipated solely as mechanical work. In practice however nothing is perfect; there will always be some heat losses etc; but (hopefully) you get the idea.

Even if the principles still seem clear as mud as you read this, you should hopefully be able to see that this is an incredibly simple way of making an engine; which of course made me think "Can I get this to work? One way to find out, let's build it!". I checked the status of the patent, and it seems to have expired as of 2016, so I'm (hopefully) in the clear.