lee webster

Well-Known Member

I am nearly ready to try a casting using patterns made with my resin 3D printer.

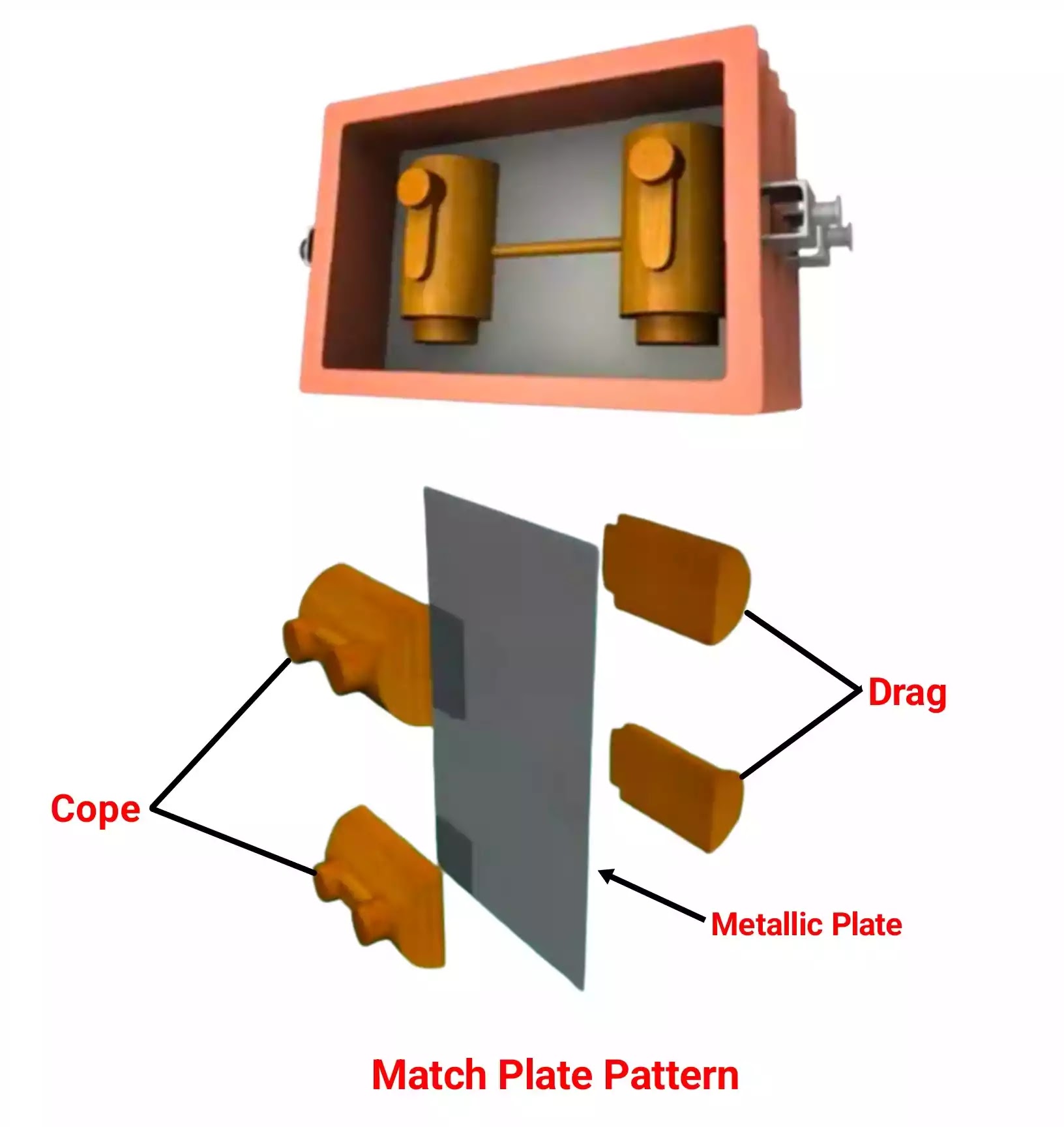

I printed the conrod pattern with my resin printer and the baseplate with my Ender3. The baseplate will need the layer lines filled in, but that's a simple task. The plate has two raised bosses that the conrod sits on. The conrod will be glued onto the plate and any minor impefections filled. I will make a frame that fits around the plate to create a mould for either resin bound sand or maybe sodium silicate bound sand. I might try both. I still have to work out how to create a way in for the molten aluminium. The hole in the little and big ends are 6mm dia, the conrod is 89mm long, I forgot to include a rule for scale. The first picture shows a different conrod alongside the one I will cast.

I printed the conrod pattern with my resin printer and the baseplate with my Ender3. The baseplate will need the layer lines filled in, but that's a simple task. The plate has two raised bosses that the conrod sits on. The conrod will be glued onto the plate and any minor impefections filled. I will make a frame that fits around the plate to create a mould for either resin bound sand or maybe sodium silicate bound sand. I might try both. I still have to work out how to create a way in for the molten aluminium. The hole in the little and big ends are 6mm dia, the conrod is 89mm long, I forgot to include a rule for scale. The first picture shows a different conrod alongside the one I will cast.