mklotz

Well-Known Member

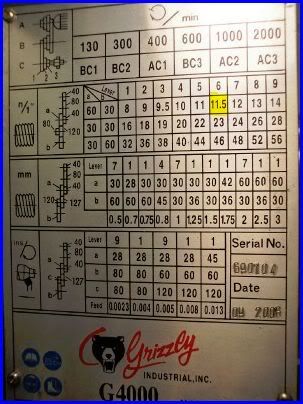

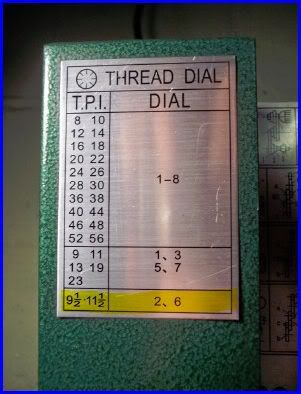

One of our club members solicited my help in cutting an 11.5 tpi thread on his lathe. (Don't you just wish you could get your hands on the throat of the cretin who comes up with these oddball pitches?)

The lathe has a QC (quick change) box and he has some change gears for it.

My thinking went like this... If the QC is set to cut 10 tpi, then, if I introduce a gear ratio of 10/11.5 into the train leading up to the input to the QC box, the lathe will now cut an 11.5 tpi thread on the 10 tpi setting. I picked the 10 tpi setting because

10/11.5 = 40/46

and he has 40 and 46 tooth change gears.

I don't see any problem with this approach since it entails doing something almost identical to installing the change gears used to shift an Imperial lathe to cutting metric threads.

Nevertheless, I've never done this personally so I'm raising the question here for comments, criticisms, etc.

Will it work?

What are the potential gotchas?

Has anyone done something similar?

The lathe has a QC (quick change) box and he has some change gears for it.

My thinking went like this... If the QC is set to cut 10 tpi, then, if I introduce a gear ratio of 10/11.5 into the train leading up to the input to the QC box, the lathe will now cut an 11.5 tpi thread on the 10 tpi setting. I picked the 10 tpi setting because

10/11.5 = 40/46

and he has 40 and 46 tooth change gears.

I don't see any problem with this approach since it entails doing something almost identical to installing the change gears used to shift an Imperial lathe to cutting metric threads.

Nevertheless, I've never done this personally so I'm raising the question here for comments, criticisms, etc.

Will it work?

What are the potential gotchas?

Has anyone done something similar?