- Joined

- Jul 16, 2007

- Messages

- 2,993

- Reaction score

- 1,061

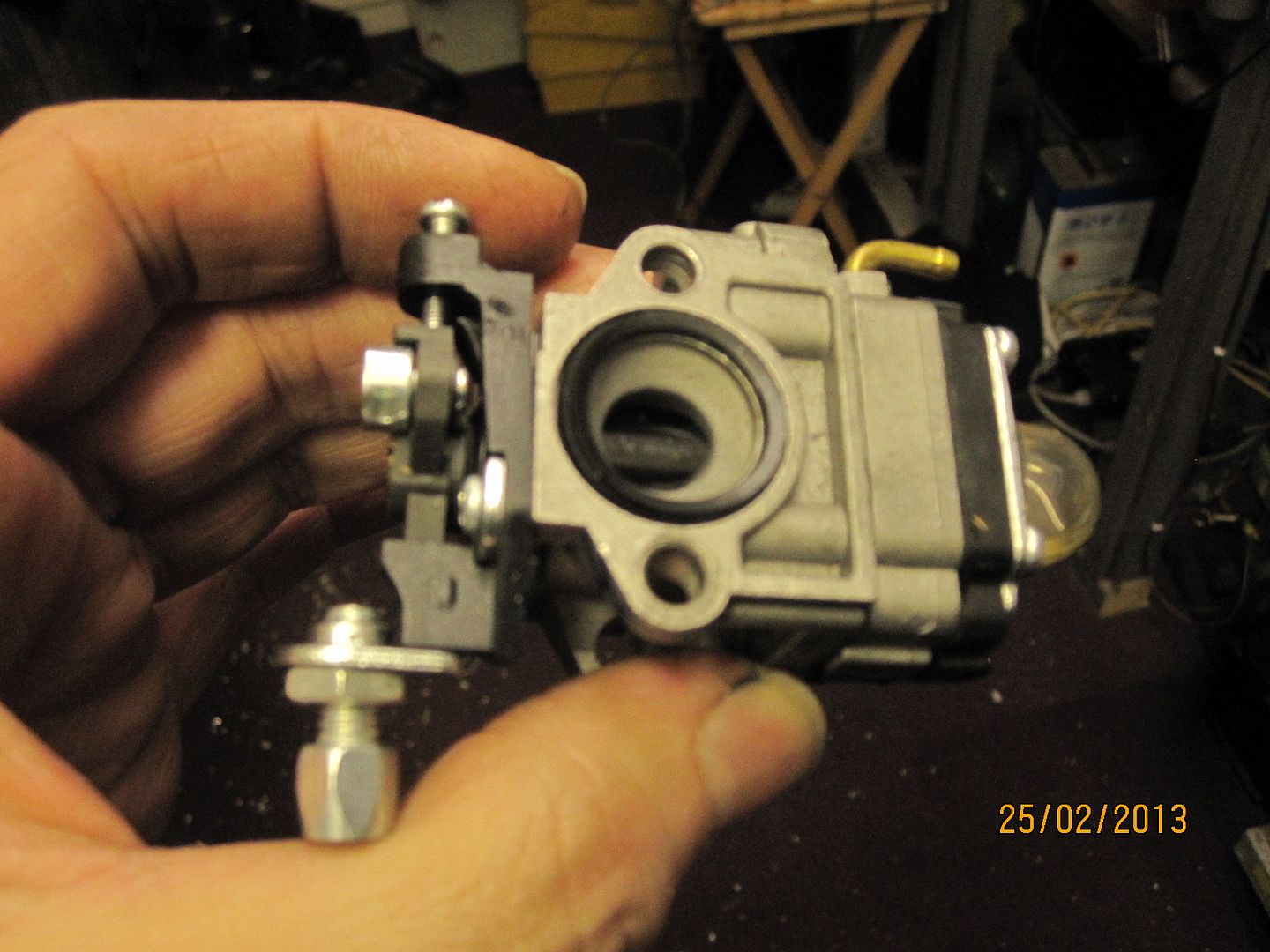

I use a similar carb on my 302 engine for running while I have replicated the internal features into a miniature copy of the actual carb for my engine. The carb you are using is commonly referred to as an air bleed carb. As was already stated the main needle is adjusted for high rpm running while the air bleed screw is to reduce the vacuum signal at idle so it doesn't pull as much fuel and go rich.

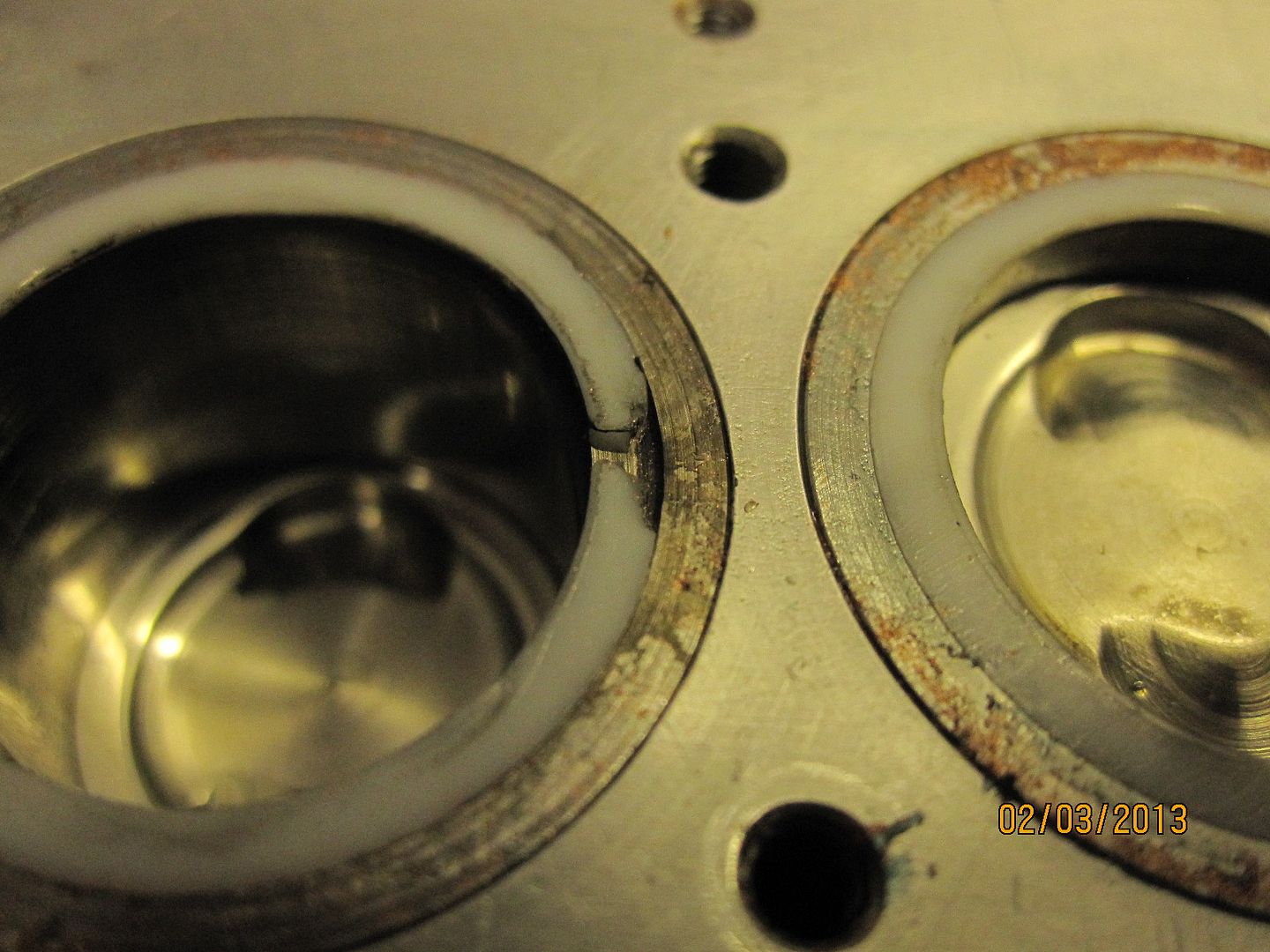

While experimenting with different carbs on my 302 I ended up with this type. I'm not saying that others won't work but this type proved to be the best of the bunch. As far as venturi size, my 302 has a bore of 1.00 and a stoke of .900. My venturi size is .200 and the engine runs fine. It's easier to start with a small hole and work up then the other way around.

gbritnell

While experimenting with different carbs on my 302 I ended up with this type. I'm not saying that others won't work but this type proved to be the best of the bunch. As far as venturi size, my 302 has a bore of 1.00 and a stoke of .900. My venturi size is .200 and the engine runs fine. It's easier to start with a small hole and work up then the other way around.

gbritnell