azroyhelmy

Member

- Joined

- Mar 28, 2011

- Messages

- 16

- Reaction score

- 0

Do any one have plan for blow off valve for turbo engine?

waynes world said:they are cheap to buy why would you waste your time machining one for. you can get them on ebay dime a dozen.

its basically a 40-50mm bore dia with a piston with a teflon seal each end and a spring on top of it to keep it closed until the vacuum sucks it open to relive manifold pressure off the turbo to free spool to keep it spinning at rpm between gear changes.

if you know what you are looking at you will know exactly how it works.

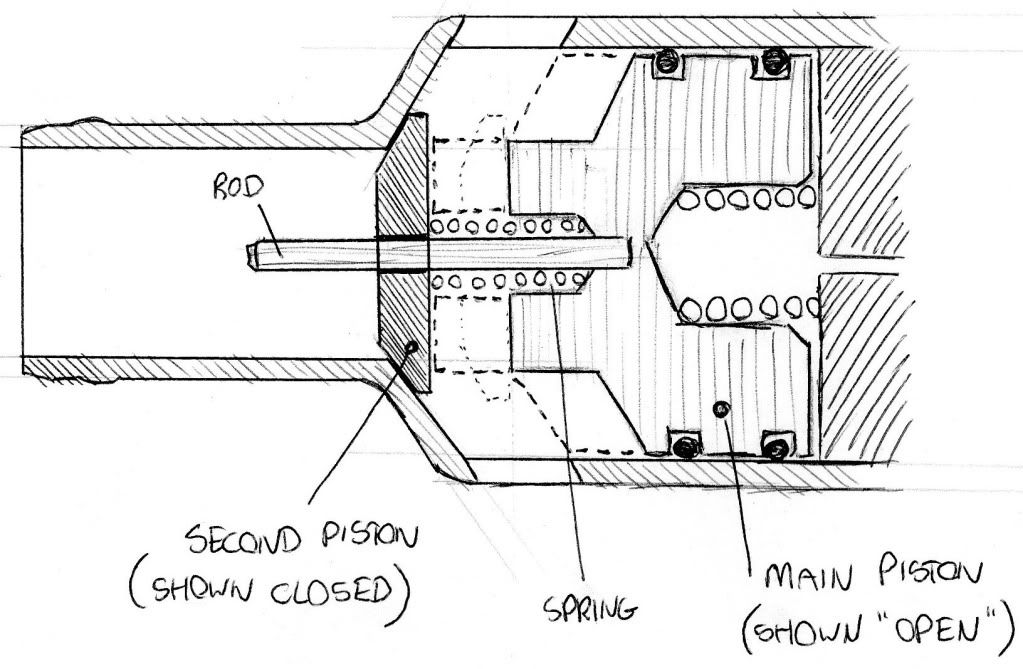

Chaffe said:as mentioned the vac on overun opens the valve against spring pressure, ive made several in the past. The important thing to remember is to keep the dia of the "seal" where the piston meets the neck on the boost side smaller than the piston dia, or it will leak when it comes on boost due to the force on the piston. Ill do a sketch of a rough design and post it if you are interested? what size dumpvalve pipe is it going onto? 1" dia or 30mm? also is the vehicle using a metered air system or is it map sensing? this will determine the need for a "twin piston valve" or simply a non return device in the valve.

Of course, the twin pistin is in fact merely a "non return valve" that also allows for some ammount of resistance before opening so a car running a metered air system does not leak metered air when on part throtle (causing running/fueling issues)NickG said:Chaffe, that's a great schematic for anybody wanting to attempt one for their car. I've always been intrigued to know how the 2 piston type work but never had 1 to take to bits or been able to find a sketch on the internet. Don't suppose you could enlighten us if you have time?

Cheers,

Nick

Enter your email address to join: