rodw

Well-Known Member

- Joined

- Dec 2, 2012

- Messages

- 1,146

- Reaction score

- 340

Hi, I am also looking at a QCTP for the Al-320. Is the tool post you purchased from Hare Forbes the "Order Code: L292" for about $200?

John

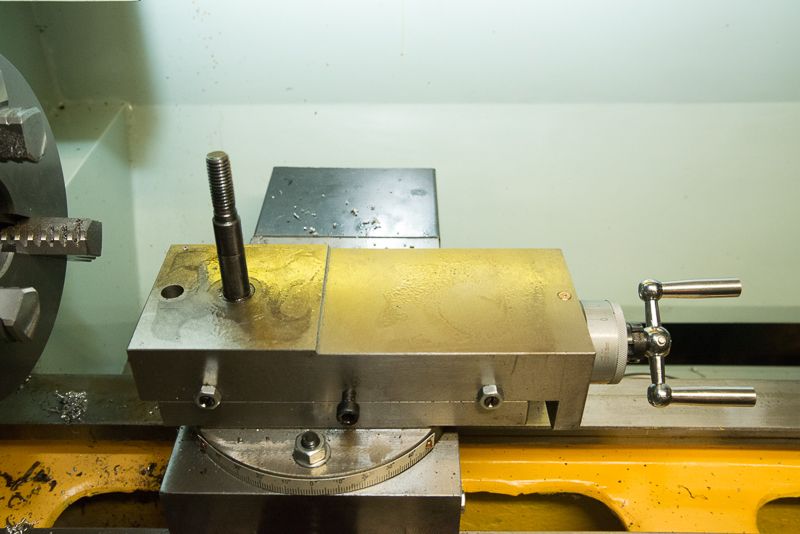

John, I am really annoyed at H&F because they don't list this QCTP for the AL250G. They tried to sell me another much more expensive item that would have been so hard to fit, even the salesman said don't bother.

But tonight just for you, I took my tablet out to my shed and compared the numbers on the photos for all the tool holders on their site for the L292 and they are exactly the same as mine which I sourced from CTC ex Hong Kong. So yes, buy it!

You will find thought the tool holders, tooling and inserts are a lot cheaper through CTC. I used to save up and spend about $500 at a time. One $800 order including $300 freight would have been $2500+ through H&F.

![IMG_20150501_115913_703[1].jpg IMG_20150501_115913_703[1].jpg](https://cdn.imagearchive.com/homemodelenginemachinist/data/attach/32/32217-IMG-20150501-115913-703-1-.jpg)

![IMG_20150501_115948_822[1].jpg IMG_20150501_115948_822[1].jpg](https://cdn.imagearchive.com/homemodelenginemachinist/data/attach/32/32218-IMG-20150501-115948-822-1-.jpg)

![IMG_20150501_120001_279[1].jpg IMG_20150501_120001_279[1].jpg](https://cdn.imagearchive.com/homemodelenginemachinist/data/attach/32/32219-IMG-20150501-120001-279-1-.jpg)

![IMG_20150501_120017_161[1].jpg IMG_20150501_120017_161[1].jpg](https://cdn.imagearchive.com/homemodelenginemachinist/data/attach/32/32220-IMG-20150501-120017-161-1-.jpg)