toolznthings

Project of the Month Winner

Here is a method I use when working with cold/mill finish round stock as purchased and with out turning the o.d. where it will be held for multiple operations. It varies as to the amount, but cold rolled stock is not round from the mill. The piece of 1" 303 stainless steel I will be working on is more than .002" out of round. It is not necessary to turn the o.d., but I need to do some other operations in relation to the outside diameter.

After sawing to rough length I use a marker and put a line down the length of the stock. Eyeball method.

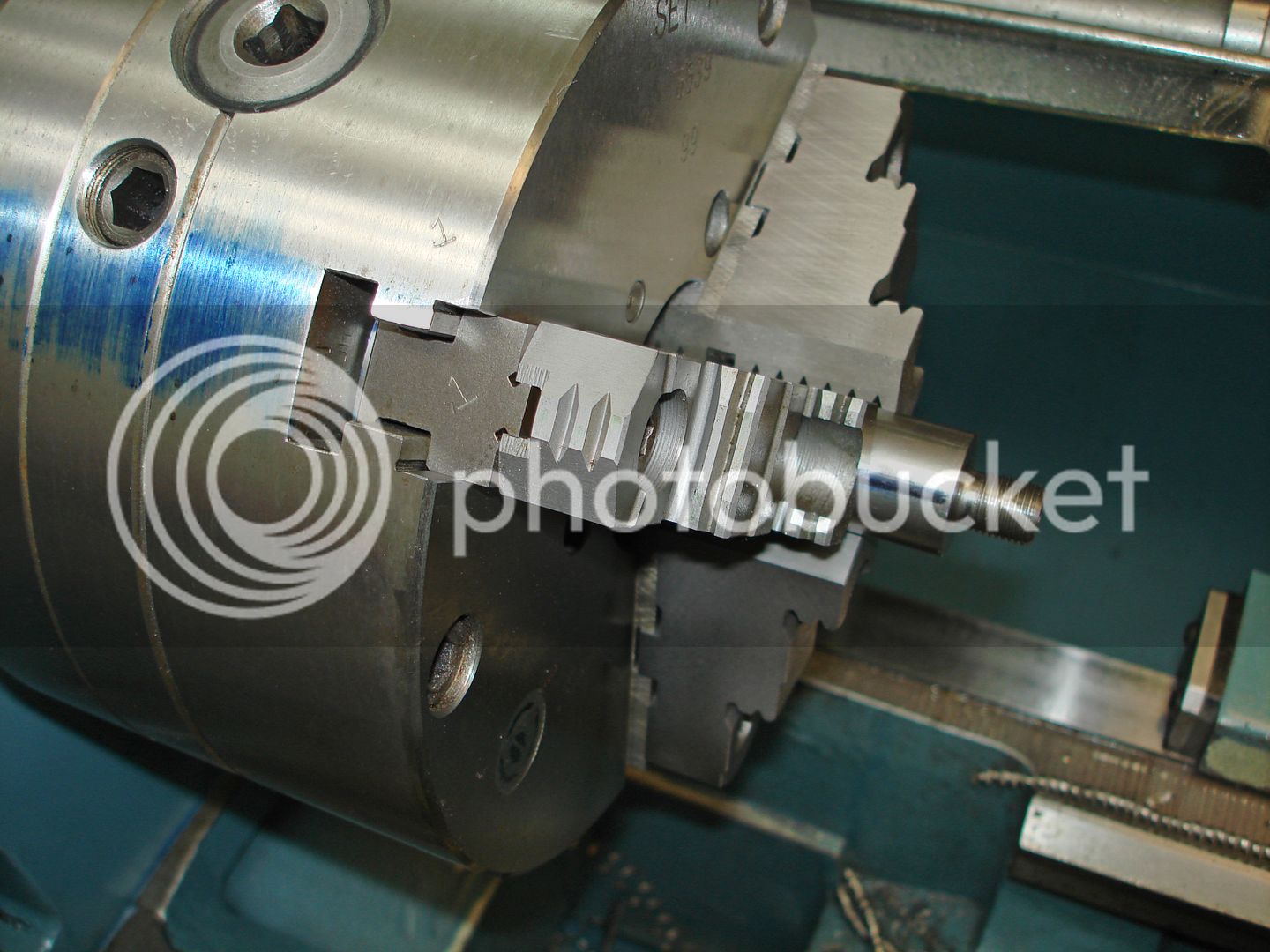

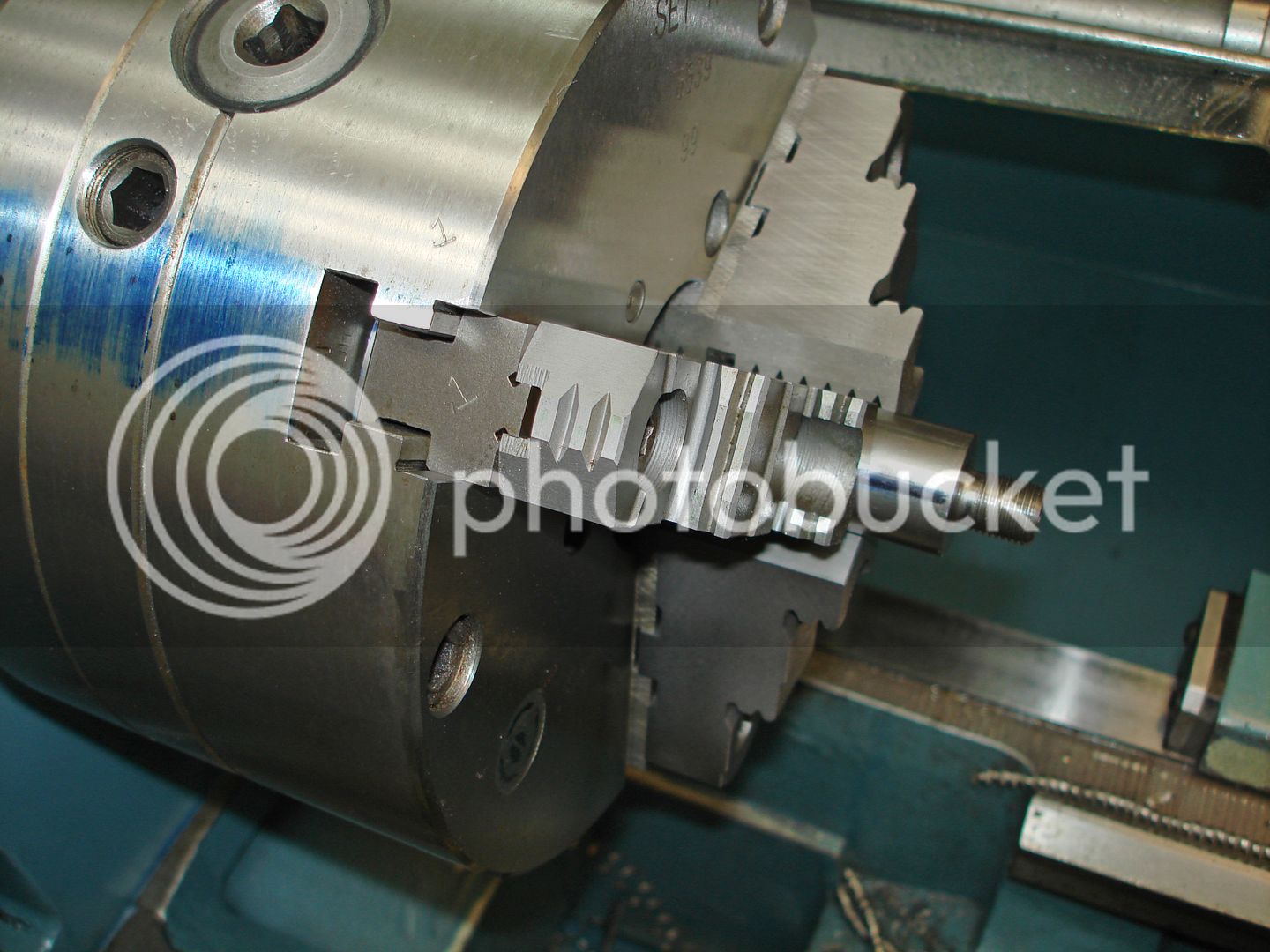

In the lathe for turning and threading one end I align the mark on the part with jaw one of the chuck. I mark the circumference of my chucks with marker at jaw one for convenience. The chuck is adjustable "Buck" style and is running true for a 1" diameter. Dialed in with a ground dowel.

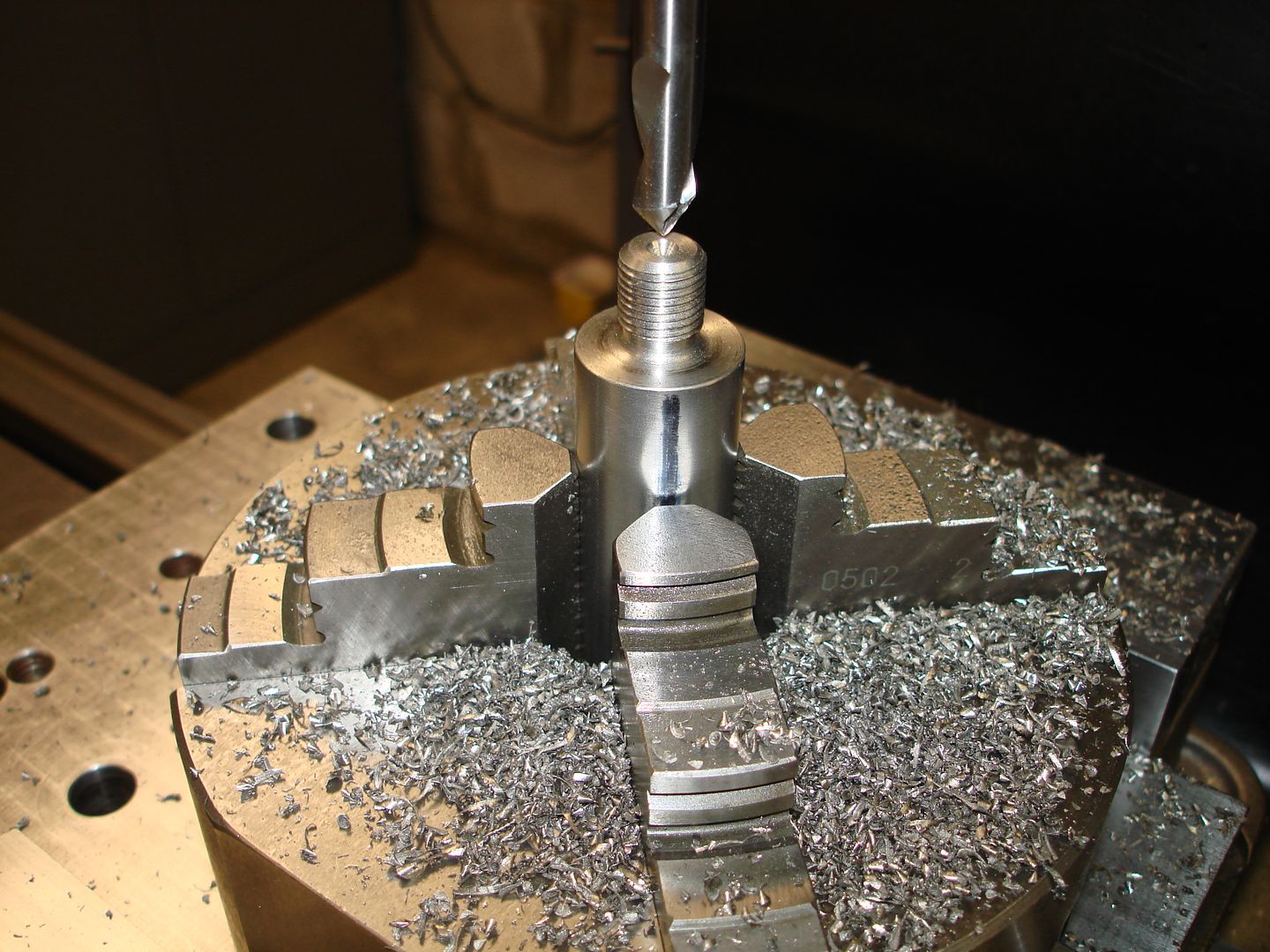

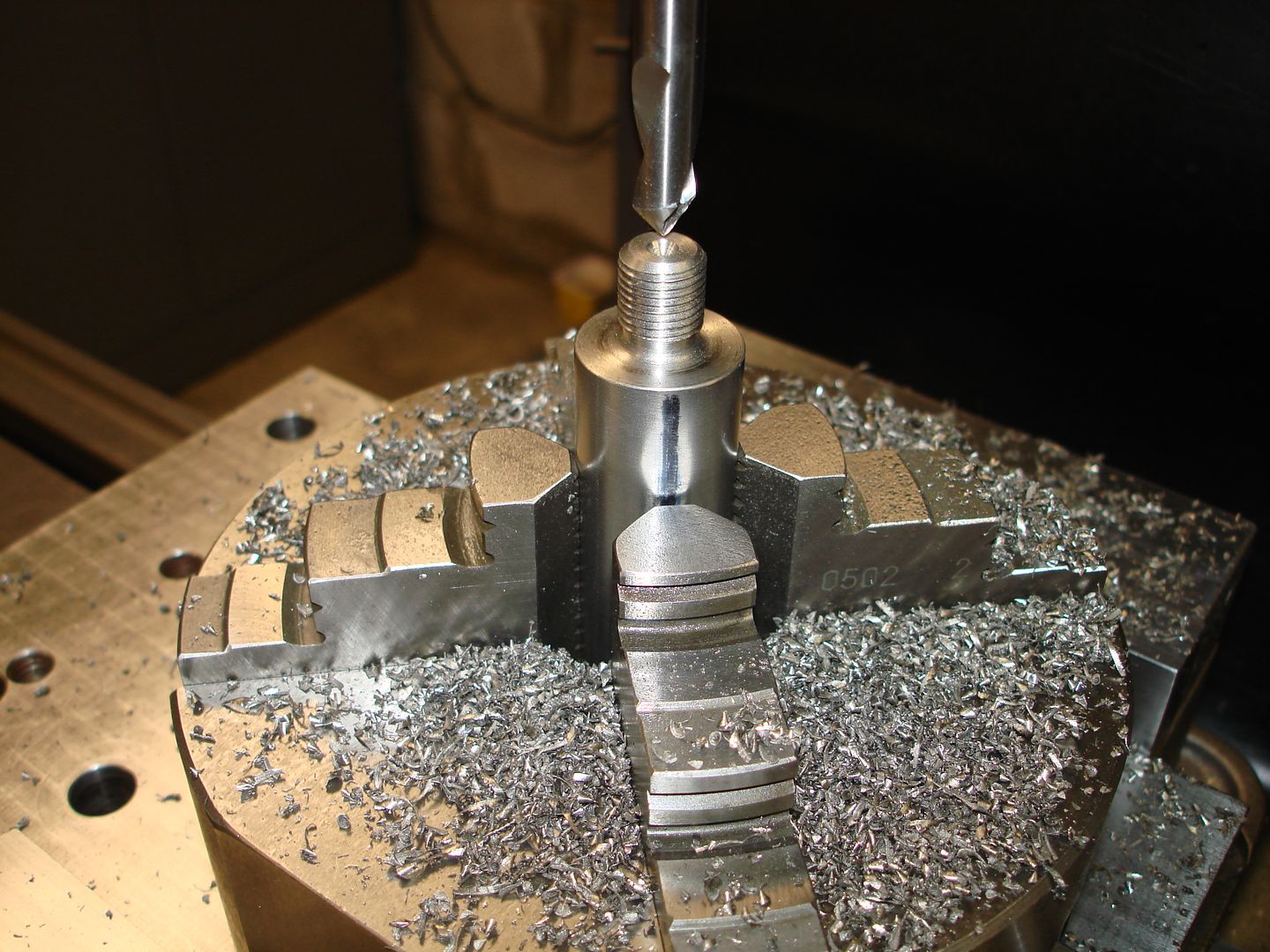

In this case I will be drilling a .166 hole thru the center of the part working from each end. Setting up a 4 jaw universal chuck at the mill I indicate a ground 1" piece of stock to find center. Then I can chuck on the mark with the same jaw and spot drill each end referencing to the mark each time.

Drilling from each end. The part is about 3 7/8" long.

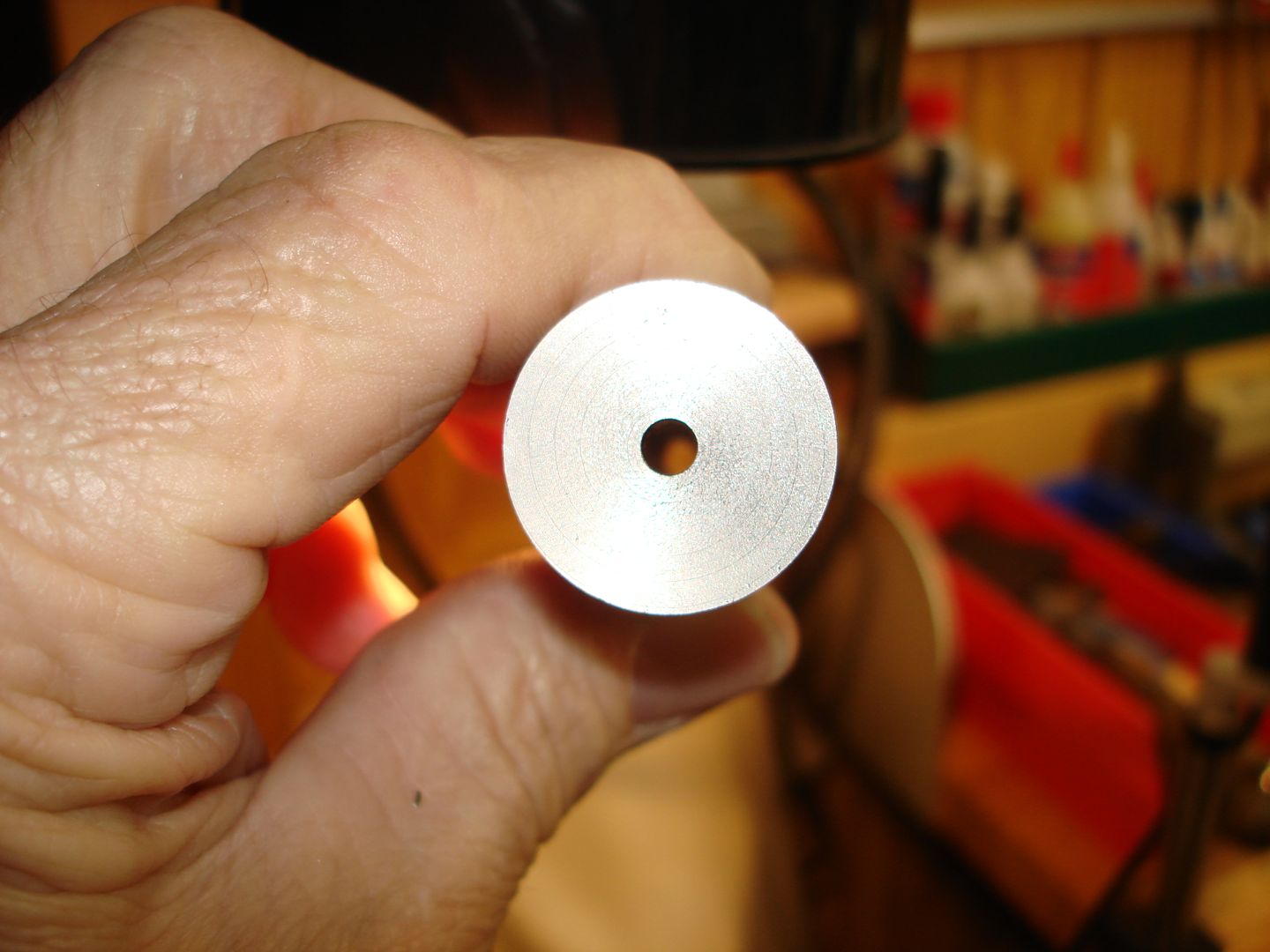

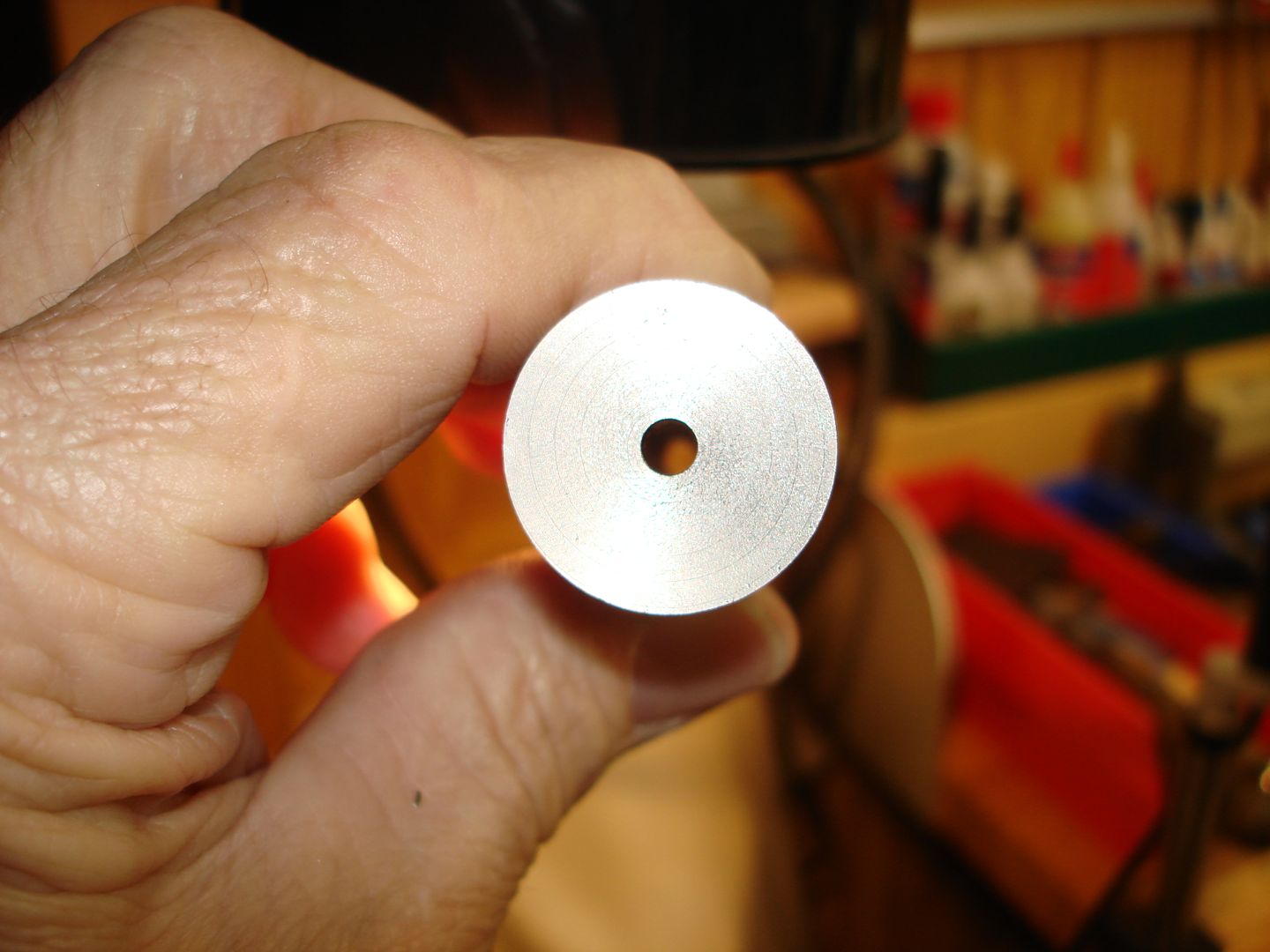

And the results with a nice matching drilled hole and more than true enough to the original stock o.d. for this part.

After sawing to rough length I use a marker and put a line down the length of the stock. Eyeball method.

In the lathe for turning and threading one end I align the mark on the part with jaw one of the chuck. I mark the circumference of my chucks with marker at jaw one for convenience. The chuck is adjustable "Buck" style and is running true for a 1" diameter. Dialed in with a ground dowel.

In this case I will be drilling a .166 hole thru the center of the part working from each end. Setting up a 4 jaw universal chuck at the mill I indicate a ground 1" piece of stock to find center. Then I can chuck on the mark with the same jaw and spot drill each end referencing to the mark each time.

Drilling from each end. The part is about 3 7/8" long.

And the results with a nice matching drilled hole and more than true enough to the original stock o.d. for this part.