- Joined

- Dec 14, 2007

- Messages

- 1,181

- Reaction score

- 31

I've been wanting to finish my Hoglet;

http://www.homemodelenginemachinist.com/index.php?topic=1831.0

But most of my time has been spent with my 18 month old Son (lots of fun) and working on my 55+ year old house (not much fun)

I tore out some kitchen cabinets which were built from 2x4's and cedar planks and added counter top outlets and a dedicated circuit for the microwave. Our kitchen is small and we need maximum storage space. The ultimate goal of this exercise is to make room for a dishwasher, aka "The Relationship Saver", which we need desperately.

I thought I would share some of the machining aspects of the project.

So of course before we can build anything we need to design and build our jigs and fixtures.

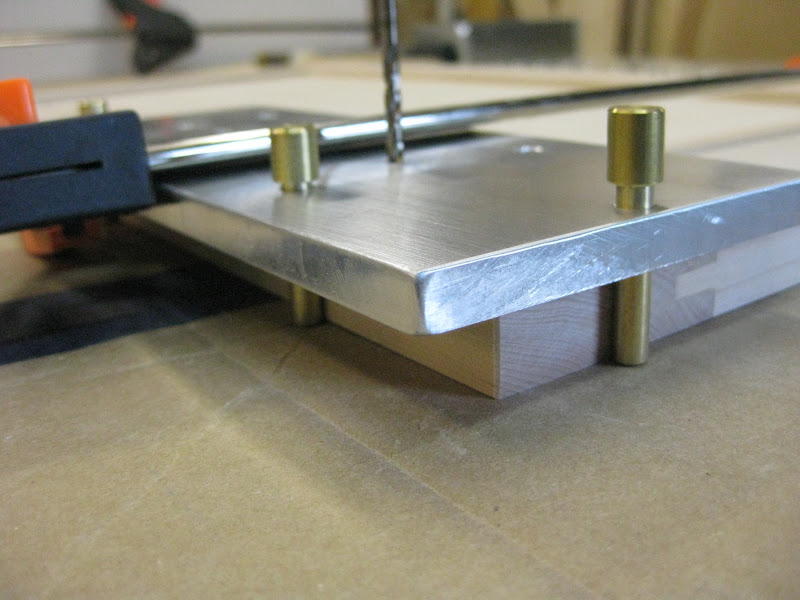

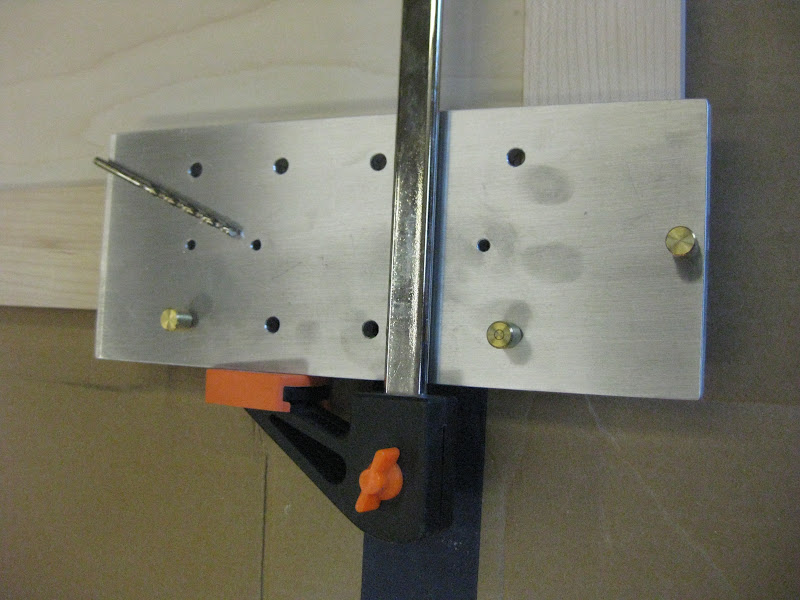

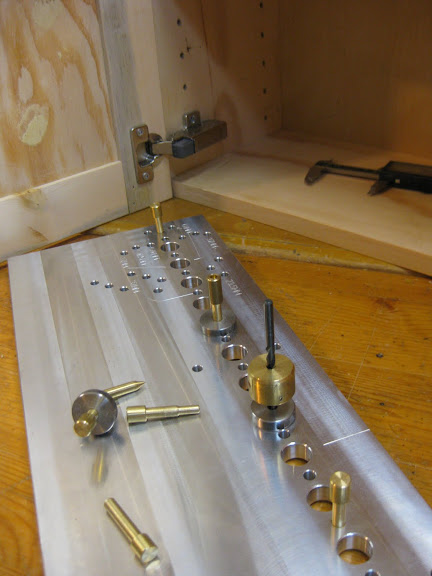

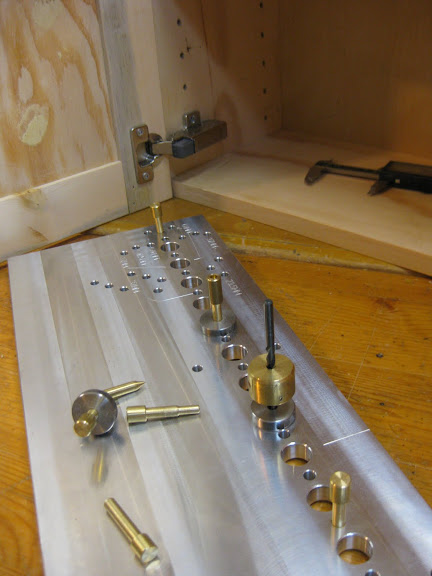

I decided to go with 32mm frameless cabinets. Here are a few shots of the drill jig I made for locating and drilling the shelf pin holes and door hinge holes as well as holes for the drawer slides.

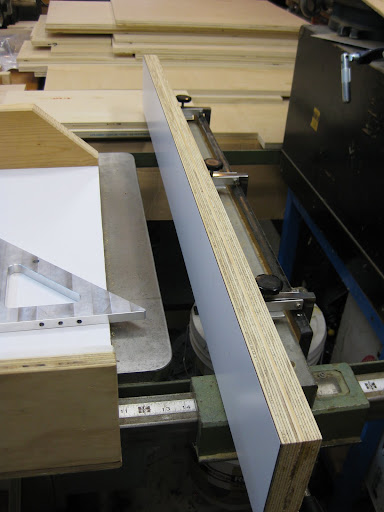

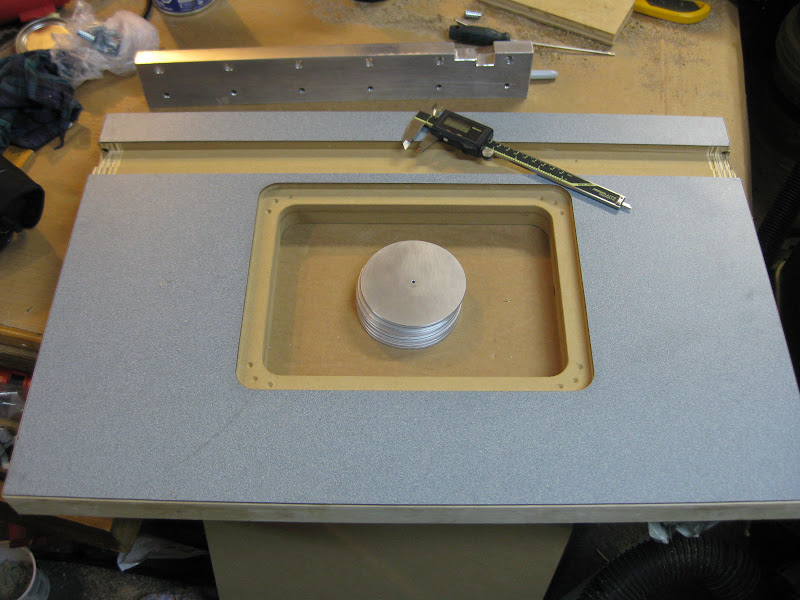

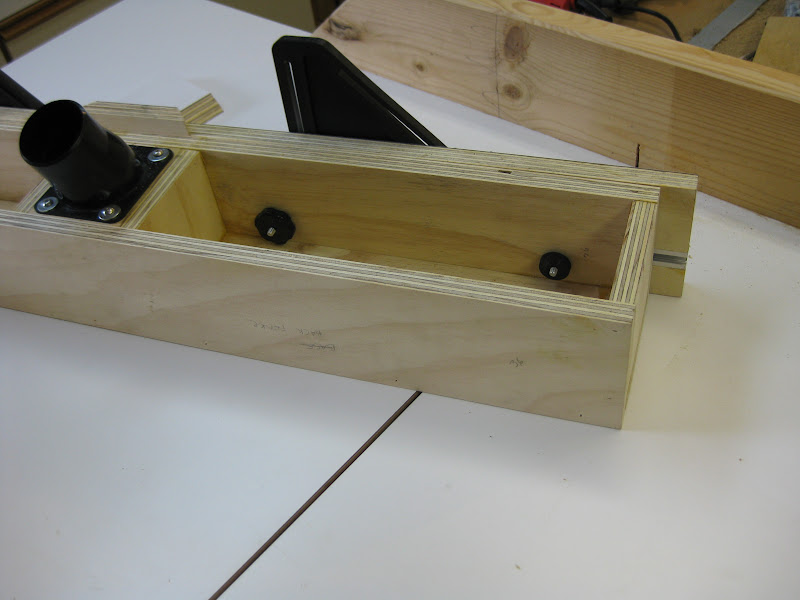

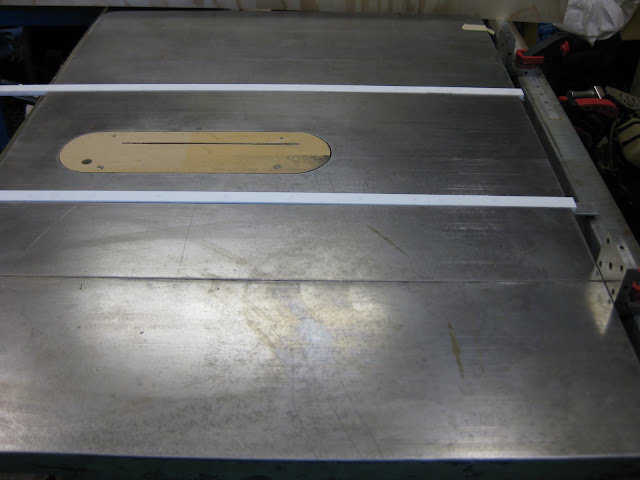

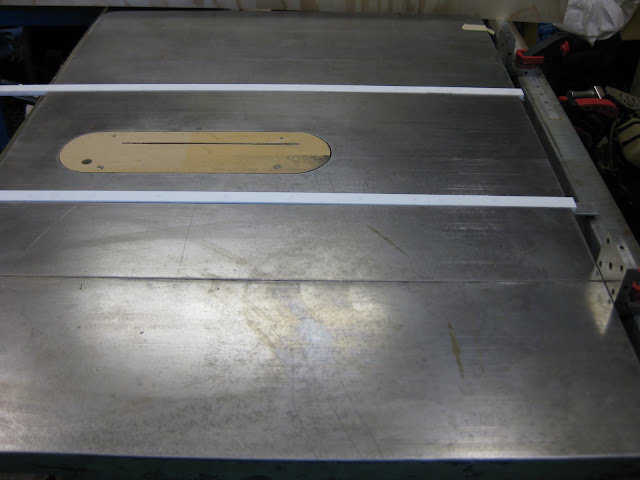

To cut the panels I needed a sled for the table saw. I started by machining teflon runners to have a sliding fit in the mitre gauge slots;

I put double sided tape on them, dropped the base on and installed the counter sunk screws;

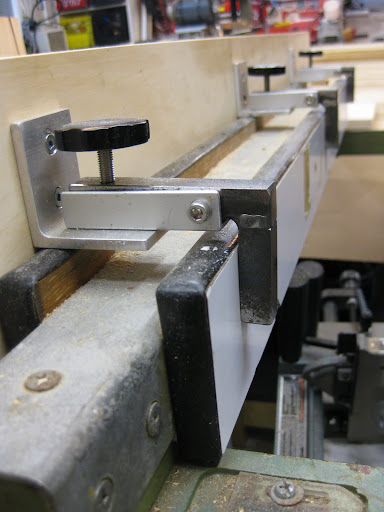

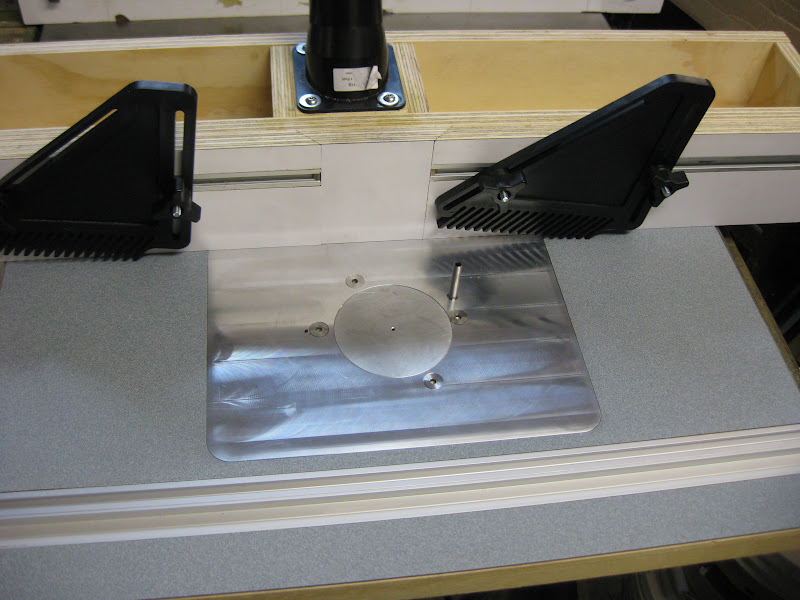

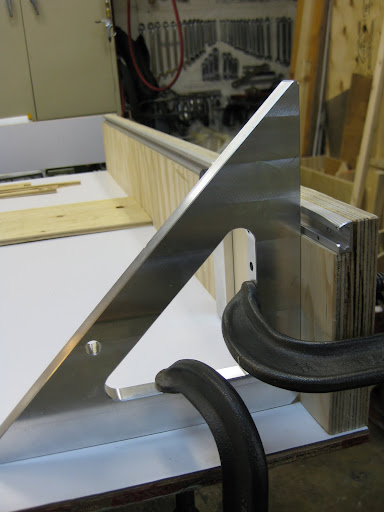

Plastic laminate was used to cover the face and I made a fence with t-track to take a sliding stop;

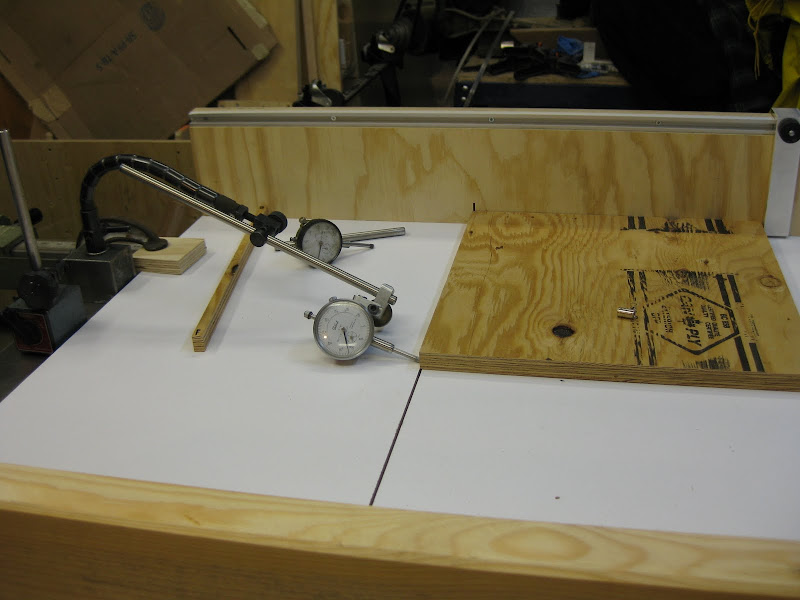

After trying the "5 cut test" method, my piece measured 2 thou taper over 12 inches. Dividing by 5 would suggest I was out .0004" over 12 inches. So I immediately went out and bought a lottery ticket.

I went out and purchased some nice maple plywood and roughed out my panels. After cutting over a dozen pieces I took a closer look and I was out closer to a thirty second over 20 inches. Unacceptable! I know my luck is never that good and it took 3 more adjustments to finally get the fence square to within 2 thou over 15 inches. I think I can live with that.

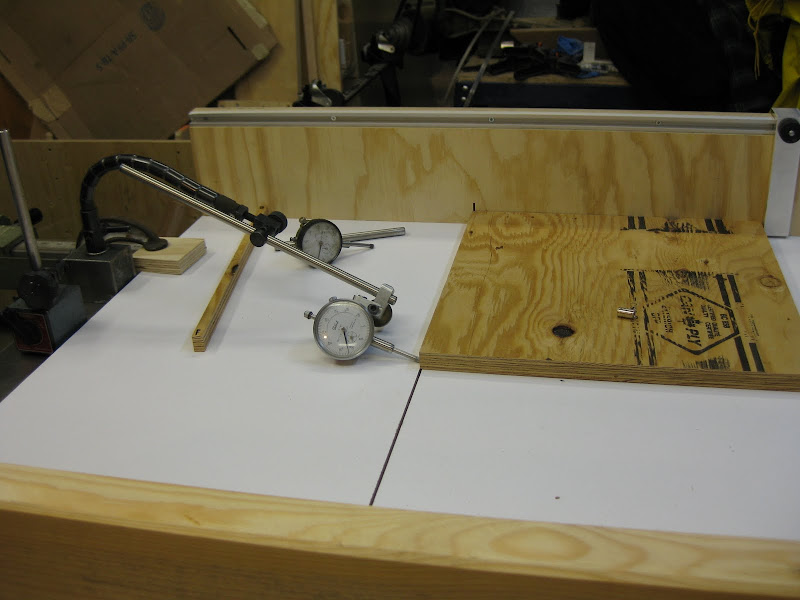

Here is my set-up for adjusting the fence;

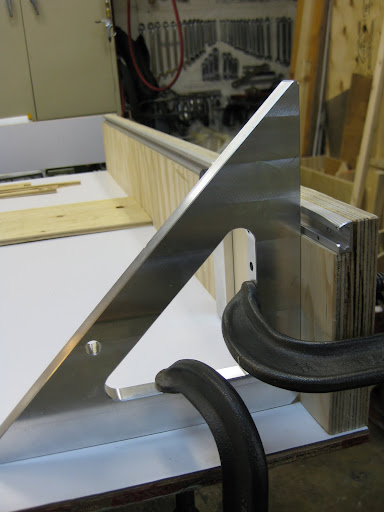

And the stop, which is keyed into the t-track to be square vertically;

And the blade guard which is to be installed once I am sure that I am happy with the squareness of it all;

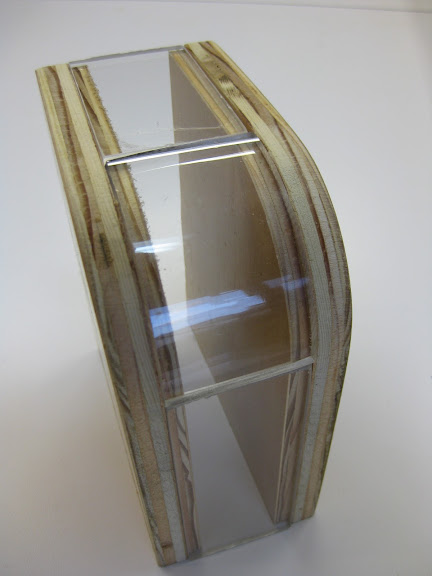

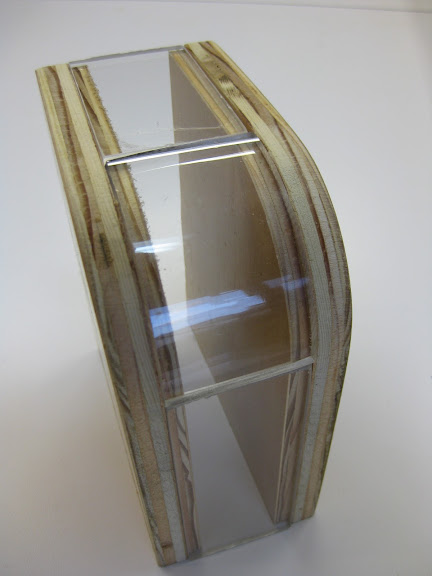

This is a practice cabinet I made, to familiarize myself with joinery technique's, from 2x4's and pieces of scrap wood I had laying around;

Thanks for looking!

http://www.homemodelenginemachinist.com/index.php?topic=1831.0

But most of my time has been spent with my 18 month old Son (lots of fun) and working on my 55+ year old house (not much fun)

I tore out some kitchen cabinets which were built from 2x4's and cedar planks and added counter top outlets and a dedicated circuit for the microwave. Our kitchen is small and we need maximum storage space. The ultimate goal of this exercise is to make room for a dishwasher, aka "The Relationship Saver", which we need desperately.

I thought I would share some of the machining aspects of the project.

So of course before we can build anything we need to design and build our jigs and fixtures.

I decided to go with 32mm frameless cabinets. Here are a few shots of the drill jig I made for locating and drilling the shelf pin holes and door hinge holes as well as holes for the drawer slides.

To cut the panels I needed a sled for the table saw. I started by machining teflon runners to have a sliding fit in the mitre gauge slots;

I put double sided tape on them, dropped the base on and installed the counter sunk screws;

Plastic laminate was used to cover the face and I made a fence with t-track to take a sliding stop;

After trying the "5 cut test" method, my piece measured 2 thou taper over 12 inches. Dividing by 5 would suggest I was out .0004" over 12 inches. So I immediately went out and bought a lottery ticket.

I went out and purchased some nice maple plywood and roughed out my panels. After cutting over a dozen pieces I took a closer look and I was out closer to a thirty second over 20 inches. Unacceptable! I know my luck is never that good and it took 3 more adjustments to finally get the fence square to within 2 thou over 15 inches. I think I can live with that.

Here is my set-up for adjusting the fence;

And the stop, which is keyed into the t-track to be square vertically;

And the blade guard which is to be installed once I am sure that I am happy with the squareness of it all;

This is a practice cabinet I made, to familiarize myself with joinery technique's, from 2x4's and pieces of scrap wood I had laying around;

Thanks for looking!