You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Whittle Aero V8 WIP

- Thread starter cobra428

- Start date

Help Support Home Model Engine Machinist Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

NOI53Y, GailInNM, wmf138,

Thanks Guys :bow:

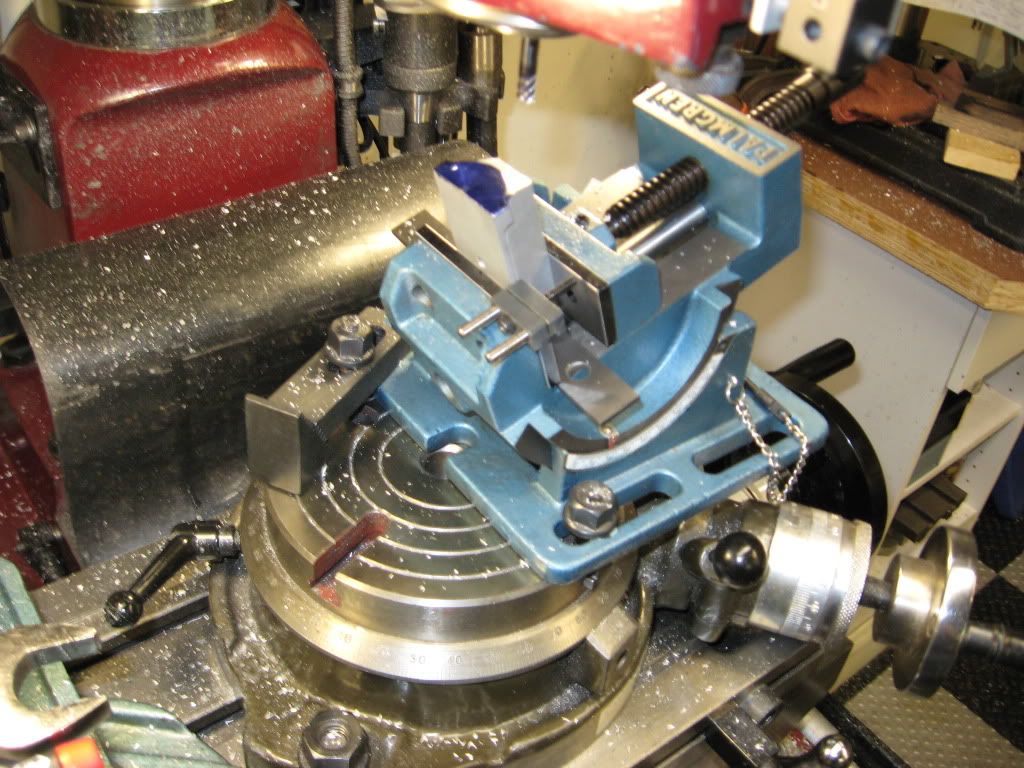

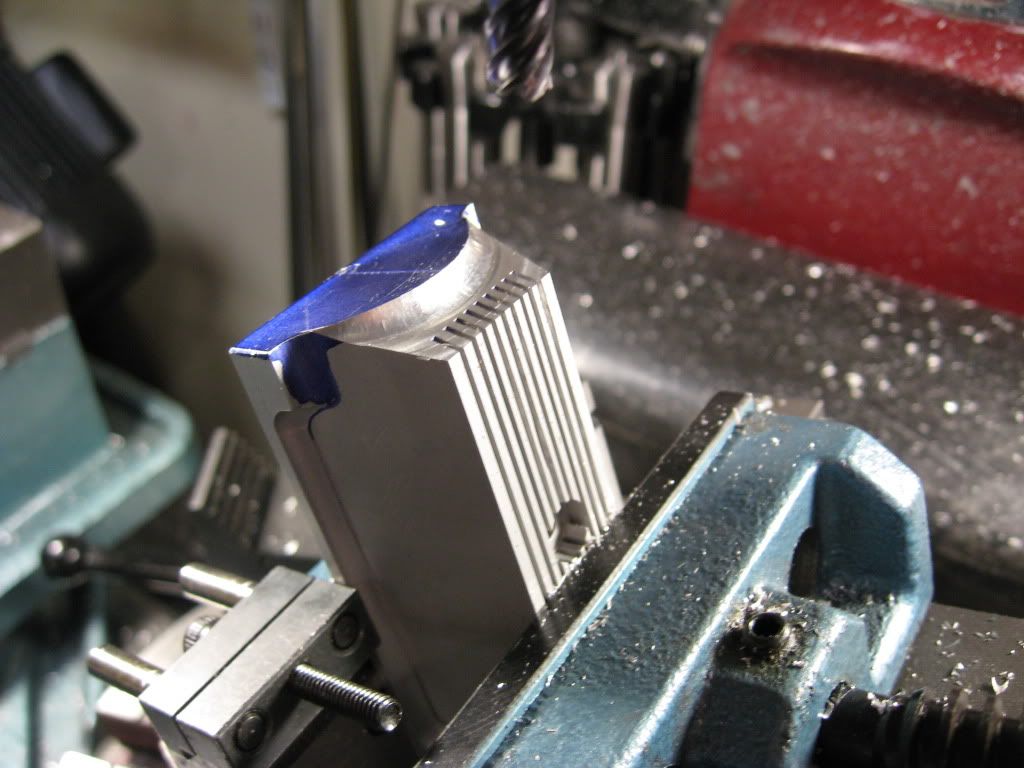

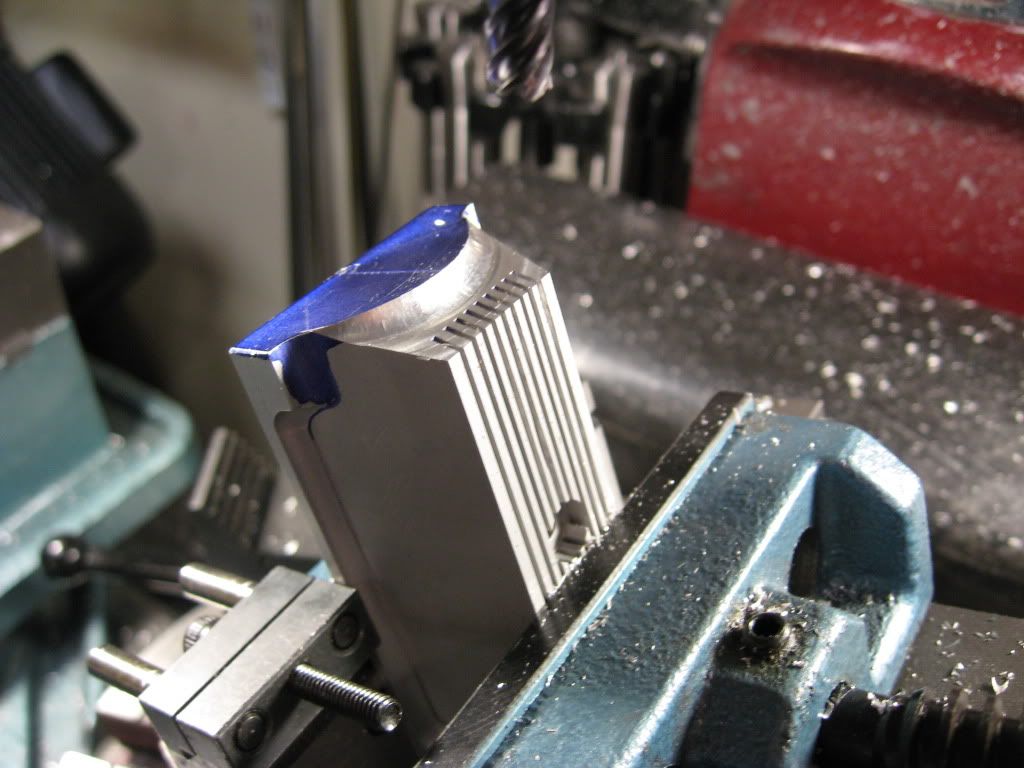

I've been :wall: :shrug: scratch.gif on how to do the front large radius that in the side view tappers. Rotor table angled and part standing on end. Or good ole mister file :shrug:

Tony

Thanks Guys :bow:

I've been :wall: :shrug: scratch.gif on how to do the front large radius that in the side view tappers. Rotor table angled and part standing on end. Or good ole mister file :shrug:

Tony

R

RobWilson

Guest

very nice Tony :bow: :bow: :bow:

Regards Rob

Regards Rob

Thanks Rob :bow:

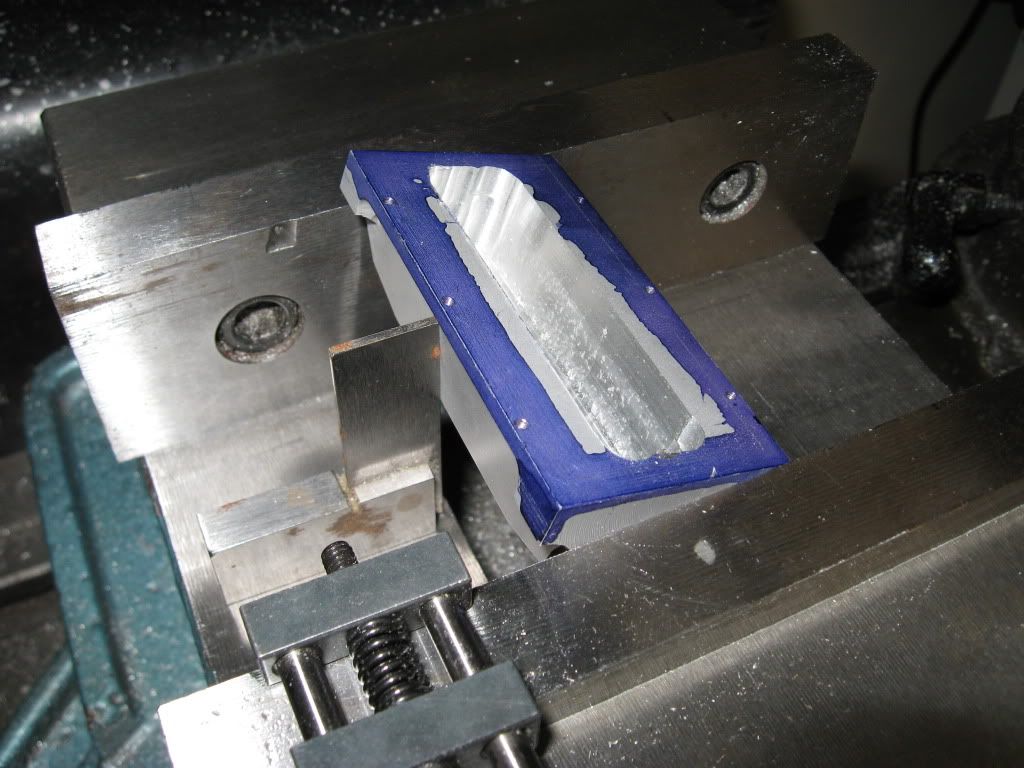

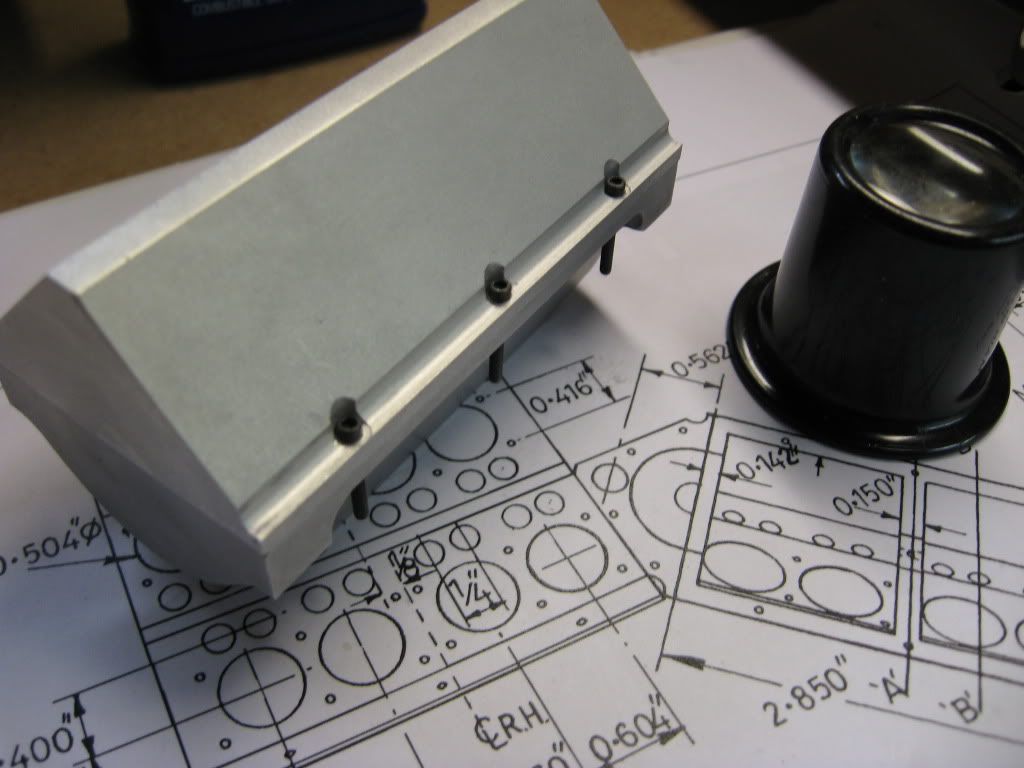

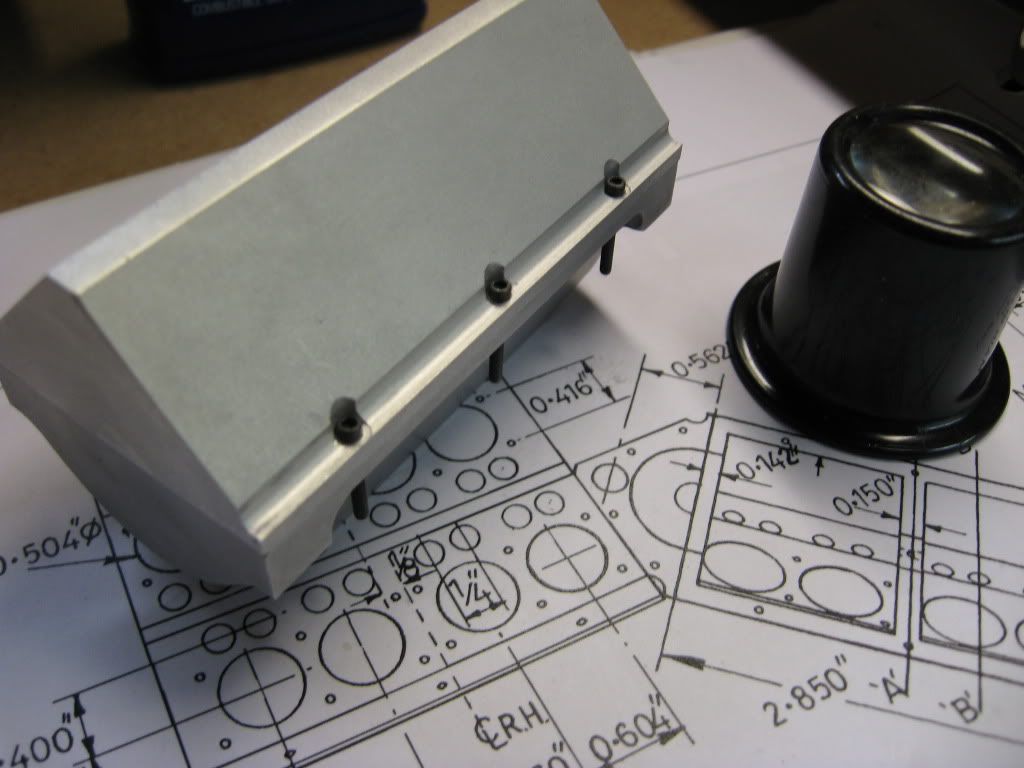

Well another installment of the lower crankcase

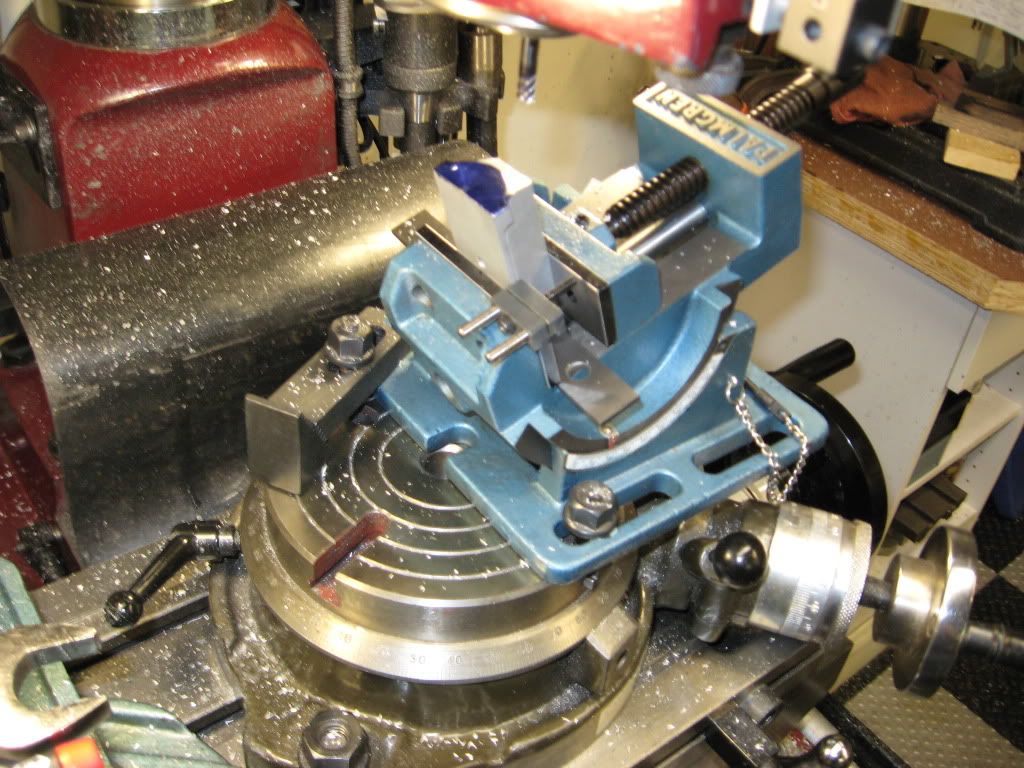

The Set up......2 hours....I knew I wasn't crazy for buying that vise

The cut.....2 min

Oh man...I actually did it

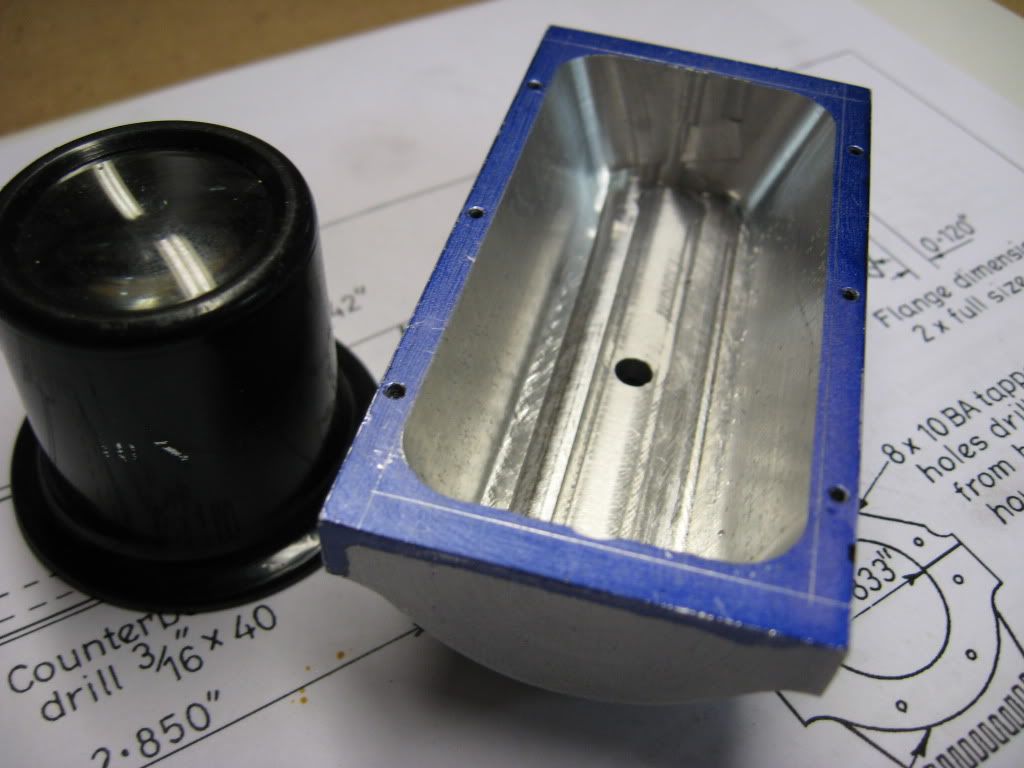

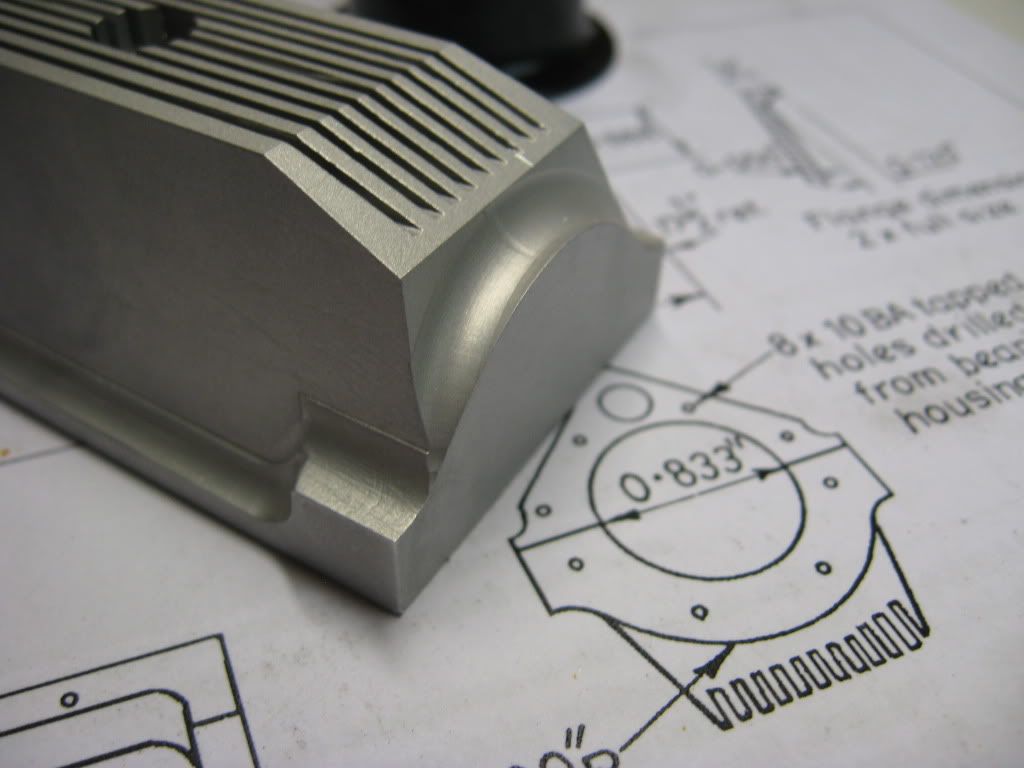

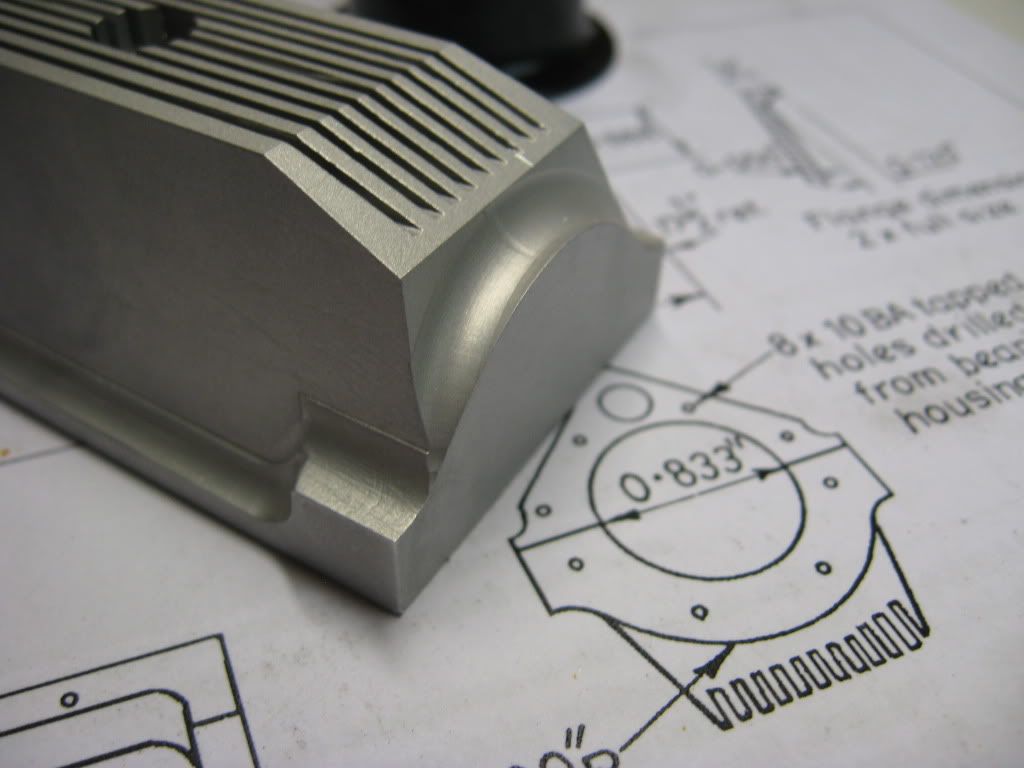

Outside Done....just some filing of the sharp edges

I might actually build this engine....the fun stuff is yet to come ...crank and camshaft scratch.gif

Tony

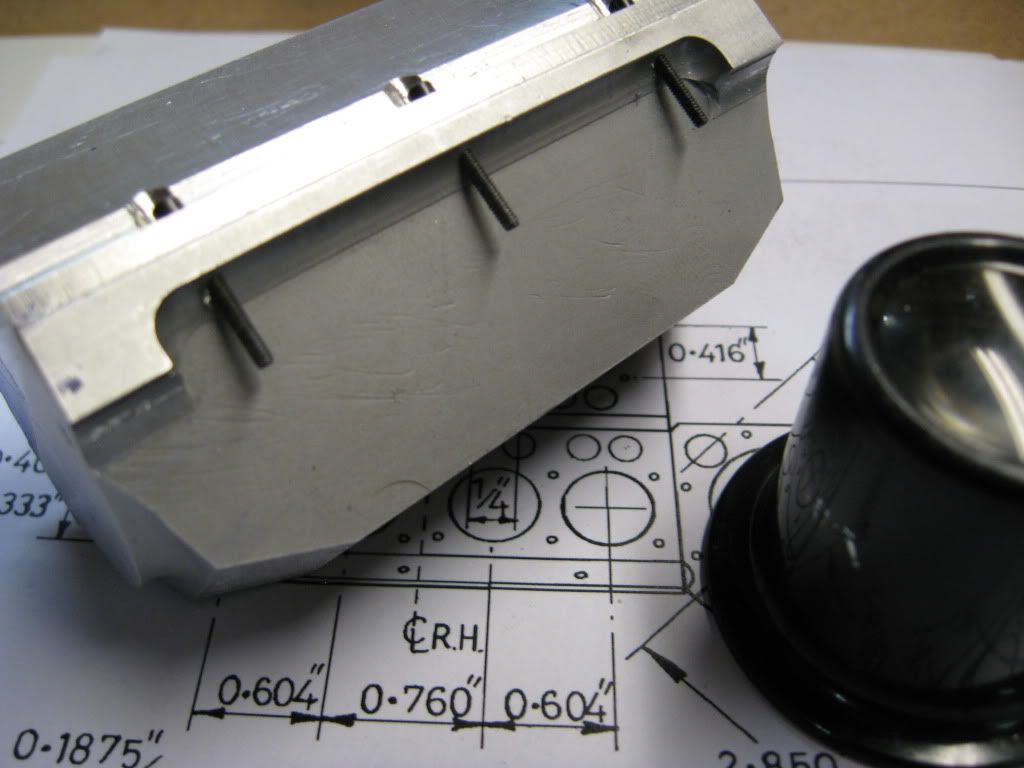

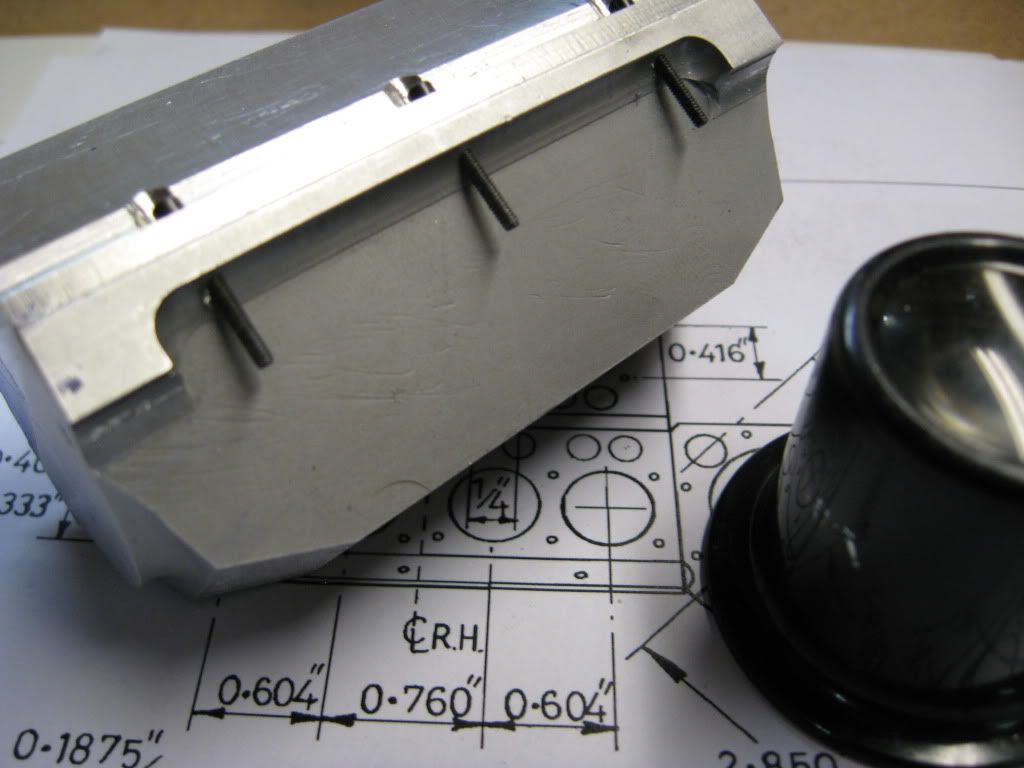

Well another installment of the lower crankcase

The Set up......2 hours....I knew I wasn't crazy for buying that vise

The cut.....2 min

Oh man...I actually did it

Outside Done....just some filing of the sharp edges

I might actually build this engine....the fun stuff is yet to come ...crank and camshaft scratch.gif

Tony

rake60

Well-Known Member

- Joined

- Jul 8, 2007

- Messages

- 4,756

- Reaction score

- 124

cobra428 said:The Set up......2 hours....I knew I wasn't crazy for buying that vise

Looking GREAT Tony!

On your "set up" time....

Machining is 80% Set Up - 10% Cutting - 6% Machine Maintenance

and 4% Clean Up.

I'd say you are right on schedule.

Rick

Thanks NOI53Y :bow:,

I don't know about the bevel thing to give you an honest answer. It's on the drawing so I put it in. I did find a place that had pics of the real engine.....know what.... in the 5 pics ....there is no view of that. And EW took some "artistic license" with his model.

Tony

I don't know about the bevel thing to give you an honest answer. It's on the drawing so I put it in. I did find a place that had pics of the real engine.....know what.... in the 5 pics ....there is no view of that. And EW took some "artistic license" with his model.

Tony

zeeprogrammer

Well-Known Member

- Joined

- Mar 14, 2009

- Messages

- 3,362

- Reaction score

- 13

Wow. Got caught here and had to read the entire thread.

Darn it. Another great thread taking away from my machining time.

Really beautiful work Tony. I hope it's less than 6 months though...for my sake.

Darn it. Another great thread taking away from my machining time.

Really beautiful work Tony. I hope it's less than 6 months though...for my sake.

Well this mornings effort

Top crankcase flanges cut drill and c'bore bottom crankcase drilled and taped

Let me tell you I was sweat-in taping those 0-80's...love to get hex head in there...we'll see

I will cut those screws down! next step cut out the insides of both

Tony

Top crankcase flanges cut drill and c'bore bottom crankcase drilled and taped

Let me tell you I was sweat-in taping those 0-80's...love to get hex head in there...we'll see

I will cut those screws down! next step cut out the insides of both

Tony

deere_x475guy

Well-Known Member

Cobra, very interesting project and a great read so far. I am looking forward to seeing more as I am sure the rest are.

vlmarshall

Well-Known Member

- Joined

- Dec 28, 2008

- Messages

- 1,138

- Reaction score

- 1

Jones said:That's a nice sump you made there

See? I'm not the only one!

(not mentioning who I'm talking to here... he knows who he is. ;D )