D

Dirty_Vinylpusher

Guest

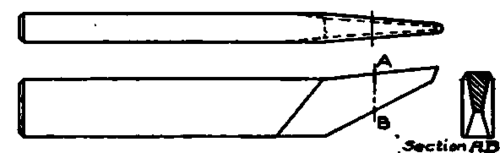

Hey guys, which tool, or rather; what shape of tool do I need to make the thing in the picture below with my lathe?

It's 60mm round stock aluminium, and I need to make a collar/flange/whatever you'd call it, on each end.

I'll need to shrink the diameter down to about 40mm in the middle section so I can drill a couple of holes in the collar at each end for bolts.

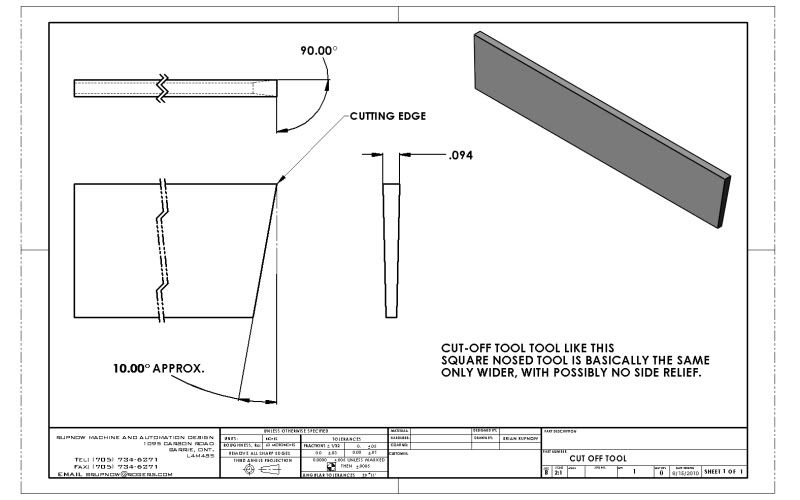

I'll most likely be making the tool myself from a piece of HSS toolsteel.

Any pictures, links or drawings greatly appreciated.

Cheers.

It's 60mm round stock aluminium, and I need to make a collar/flange/whatever you'd call it, on each end.

I'll need to shrink the diameter down to about 40mm in the middle section so I can drill a couple of holes in the collar at each end for bolts.

I'll most likely be making the tool myself from a piece of HSS toolsteel.

Any pictures, links or drawings greatly appreciated.

Cheers.