raym 11

Well-Known Member

- Joined

- Jul 21, 2007

- Messages

- 147

- Reaction score

- 0

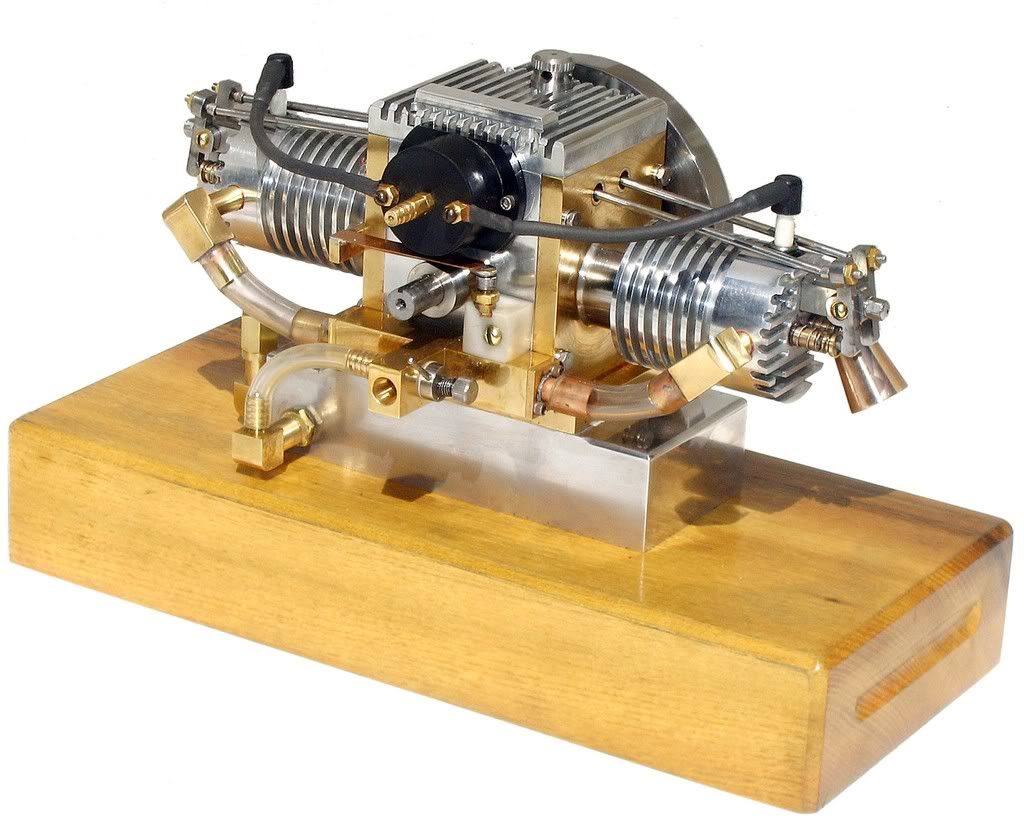

I finished this from Model Eng. Mag. last year. I'm in the process of making a propane demand valve for it to see if it will run as well as it does on camp gas & Mystery Oil.

I used Tygon tubing for the inlet manifold connections and I am not happy with it. Anybody suggest some other tubing that might work? How about hose clamps for same?, thought a few times about using 'O' rings stretched over the ends of the tubing.

Ray M