DavesWimshurst

DavesWimshurst

- Joined

- Dec 7, 2008

- Messages

- 102

- Reaction score

- 3

I eat dinner once a week with my techie friends and often want to run one of the engines I've brought. I wanted a silent air compressor.

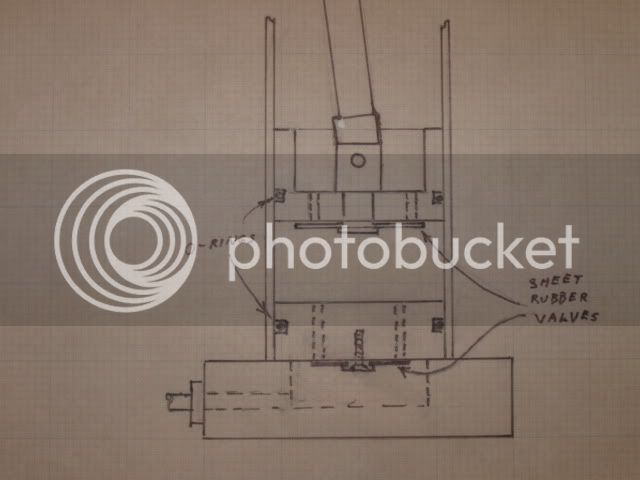

I had several feet of 2.25 inch bore brass pipe that was just begging to be used. The design I came up with is this:

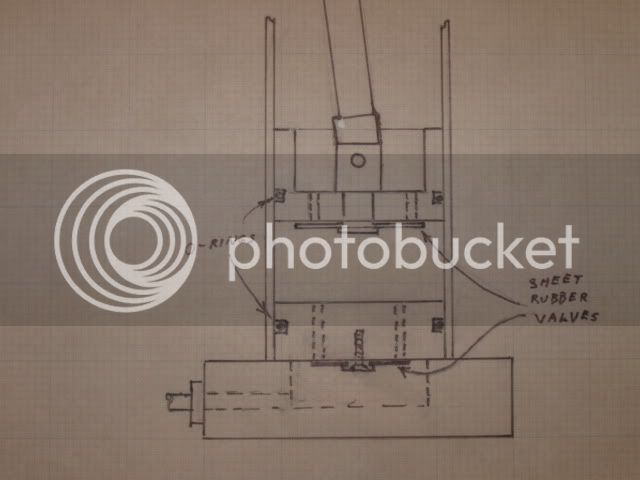

It is a two cylinder single acting pump of similar appearance to antique two man fire engine pumps. A propane cylinder as used for camping stoves provides an air reservoir and the support structure for the handle.

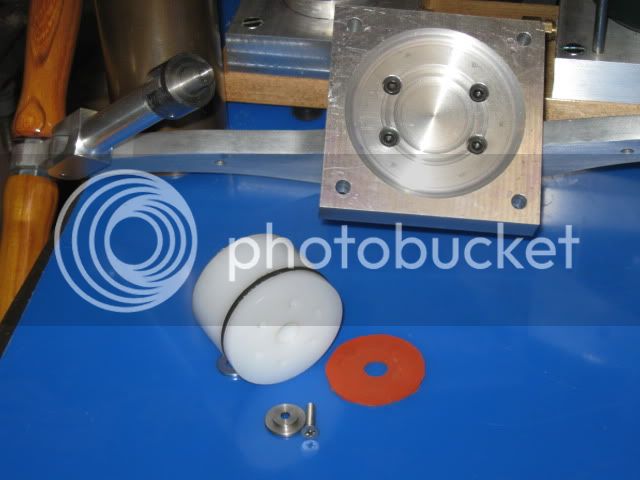

Here is a picture of the partially dismantled pump showing the valve on the bottom of one piston:

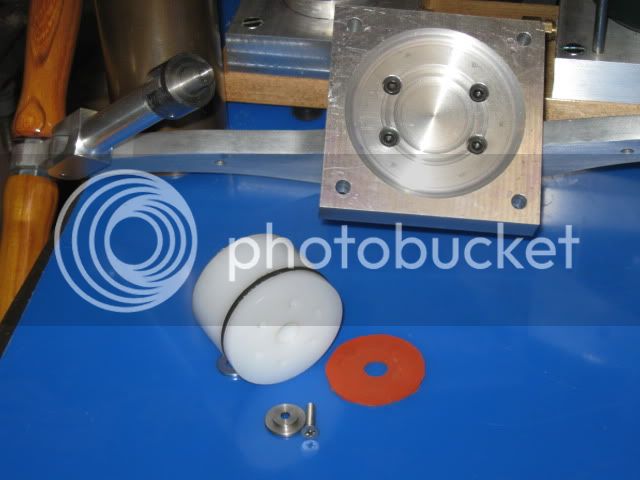

Here is the valve dismantled:

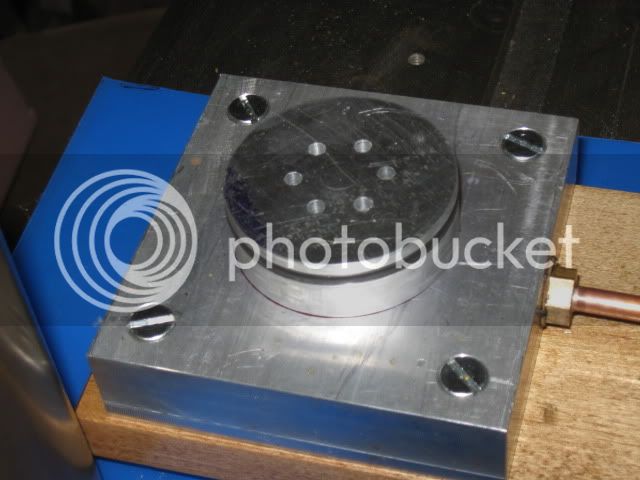

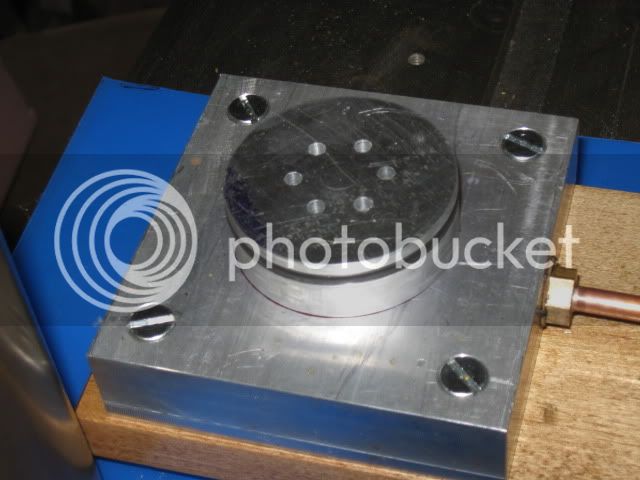

Each brass cylinder mounts over a short aluminum cylinder and is held in place and sealed by a tight fitting o-ring.

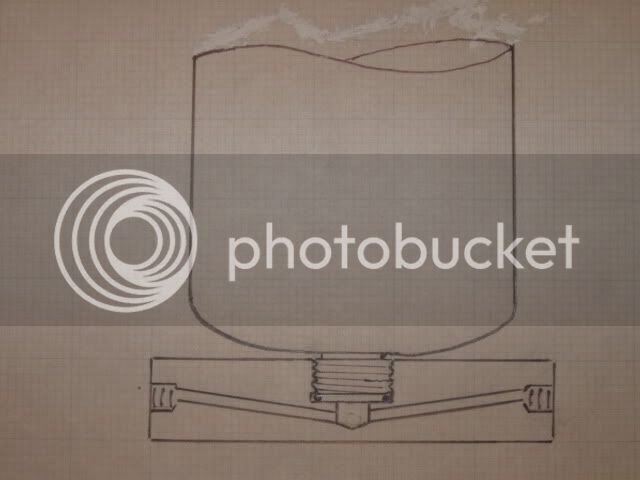

Six air holes lead to a valve chamber below the disk as shown in the sketch:

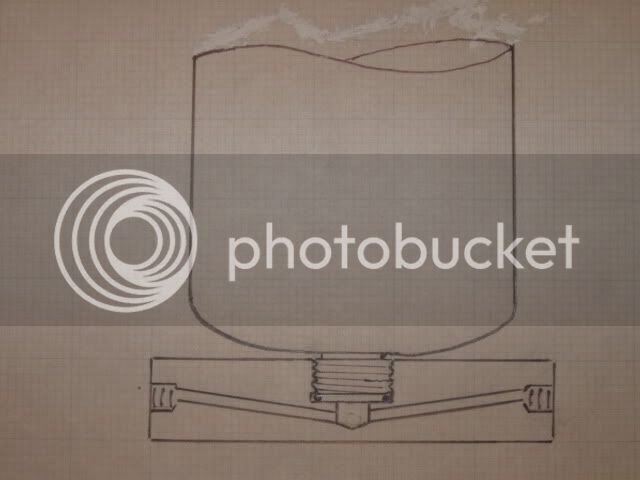

I removed the valves and baked the propane tank in a 150 deg F oven for about three days to get rid of the odorant from gas residue. I didn't know the specs for the thread on the cylinder which measures about 25 mm dia. and may be 1.25 mm pitch.

I approximated using 20 threads per inch (1.27 mm pitch) which seamed close enough since the sealing was done using an o-ring and the four long bolts provided structural stability:

Air passages connect to each pump half by copper tubing.

The piston area is about four square inches so to get 5 psi requires about 20 pounds force on the pump handles though the large pistons provide a good air flow for small engines.

The pump was made mostly from recycled materials including the osage orange wood for the handles.

A video of the pump in action:

The last engine shown is my version of Elmer's mine engine, I used a slip eccentric to get the reversing ability. I hope to get some pictures of it up soon.

Dave

I had several feet of 2.25 inch bore brass pipe that was just begging to be used. The design I came up with is this:

It is a two cylinder single acting pump of similar appearance to antique two man fire engine pumps. A propane cylinder as used for camping stoves provides an air reservoir and the support structure for the handle.

Here is a picture of the partially dismantled pump showing the valve on the bottom of one piston:

Here is the valve dismantled:

Each brass cylinder mounts over a short aluminum cylinder and is held in place and sealed by a tight fitting o-ring.

Six air holes lead to a valve chamber below the disk as shown in the sketch:

I removed the valves and baked the propane tank in a 150 deg F oven for about three days to get rid of the odorant from gas residue. I didn't know the specs for the thread on the cylinder which measures about 25 mm dia. and may be 1.25 mm pitch.

I approximated using 20 threads per inch (1.27 mm pitch) which seamed close enough since the sealing was done using an o-ring and the four long bolts provided structural stability:

Air passages connect to each pump half by copper tubing.

The piston area is about four square inches so to get 5 psi requires about 20 pounds force on the pump handles though the large pistons provide a good air flow for small engines.

The pump was made mostly from recycled materials including the osage orange wood for the handles.

A video of the pump in action:

The last engine shown is my version of Elmer's mine engine, I used a slip eccentric to get the reversing ability. I hope to get some pictures of it up soon.

Dave